258

Appendix B

Using The Standard Peel With Liner Rewinder Option

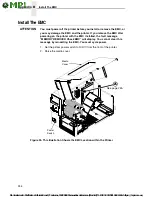

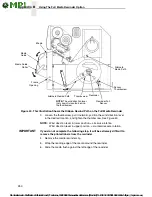

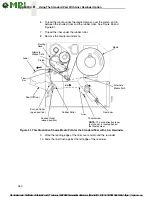

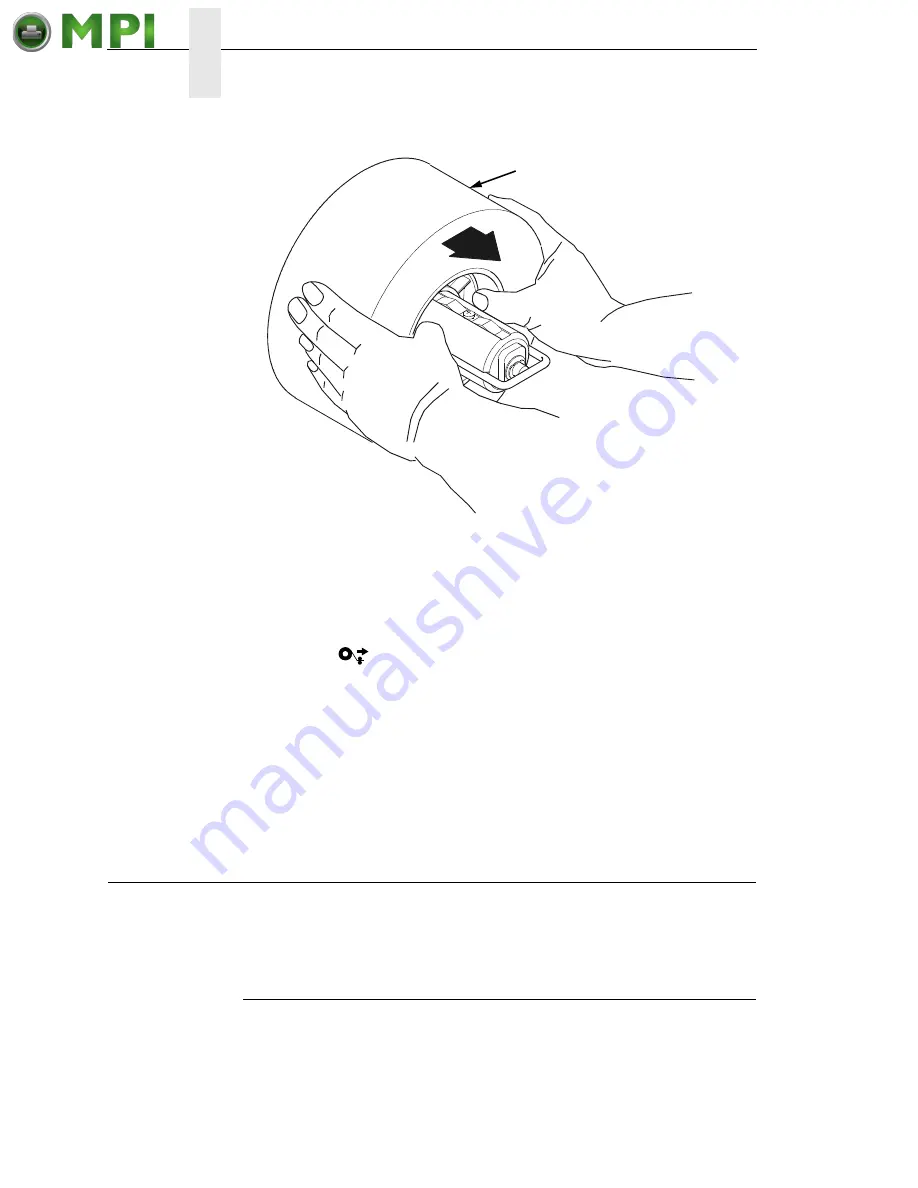

Figure 49. Removing the Media Roll

Remove Printed Media from the Rewinder

1.

Open the media cover and side cover.

2.

Press the

(Feed) key to advance the last printed label past the

printhead, and tear the liner from behind the last printed label.

3.

Manually rewind the remaining printed labels onto the media roll by

turning the media retainer (refer to Figure 48 on page 257).

4.

Loosen the thumbscrew and remove the media retainer.

5.

Remove the media roll from the rewinder as shown in Figure 49, and set

the roll aside.

6.

Close the side cover and media cover.

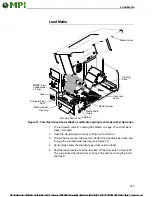

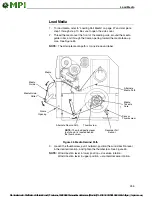

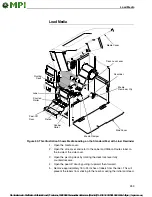

Using The Standard Peel With Liner Rewinder Option

The Standard Peel with Liner Rewinder allows you to automatically peel die-

cut labels off their liner (backing) and dispense them one at a time while

rewinding the liner.

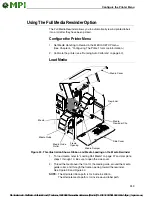

Configure the Printer Menu

1.

Set Media Handling to Peel-Off under the MEDIA SETUP menu.

(See “Configuring The Printer” on page 63 for more information.)

2.

Calibrate the printer (see “Running Auto Calibrate” on page 50).

pgr

wld10

Media Roll