(continued)

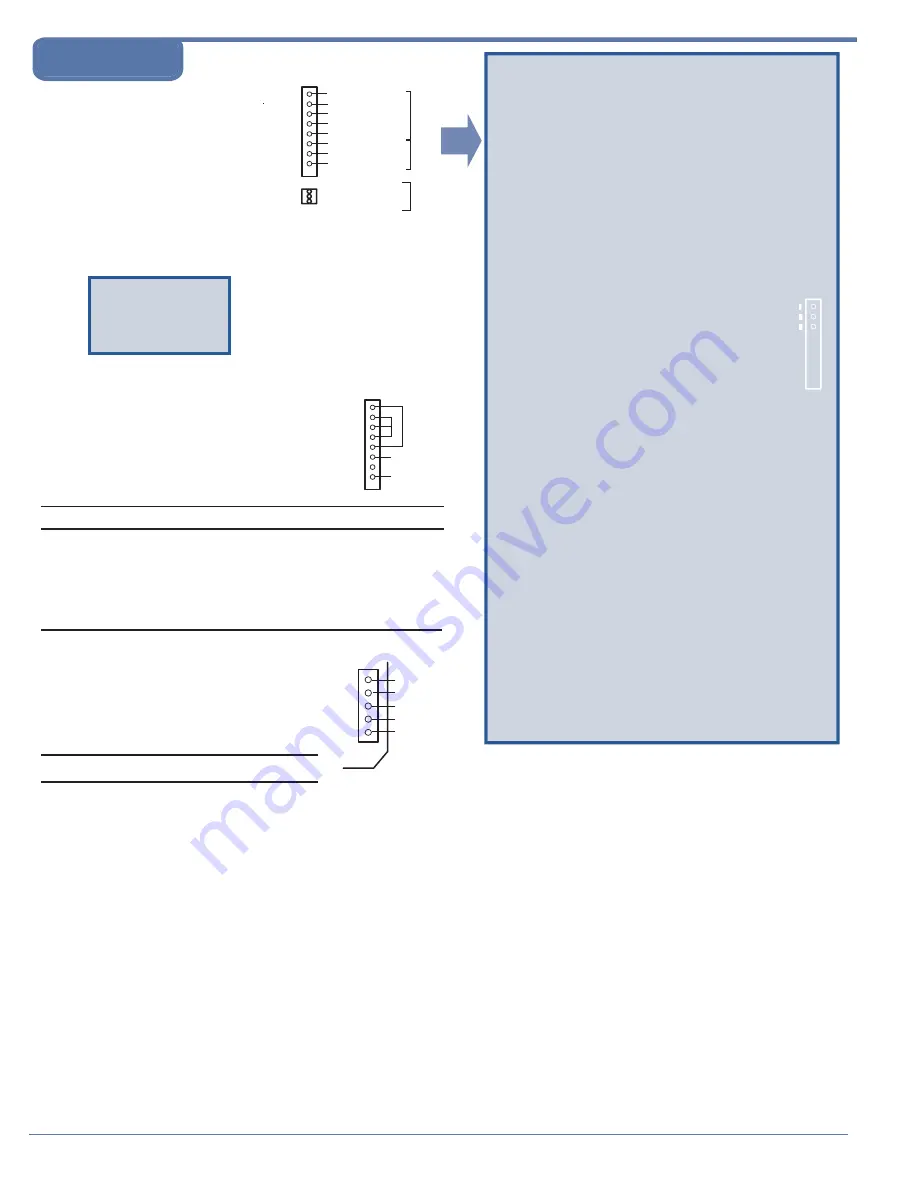

8. Connect EZServo to motor.

BLDC Motors: Connect servo motor

and Hall sensors to the eight pins of

the motor connector as shown in

diagram: (See Wiring Note on

preceding page and Hall sensor

phasing instructions on this page.)

On SV23 models, use 3-pin screw

terminal for high-current motors.

Brush motor connections: Connect brush servo motor to the eight

pins of the motor connector as shown in diagram:

(See Wiring Note on preceding page.)

9.

Ensure power is ON.

10. Test velocity function:

Issue command /1N0R to tell the board there is no encoder.

Issue command /1P0R or /1D0R endless move; then confirm response.

Issue command such as /1V10R to change speed; then confirm

response. (Hall sensors provide feedback for velocity control.)

11. If only velocity control is required, skip this step. If position

control is required, turn power OFF.

Then connect encoder to 5-pin connector

as shown in diagram:

(See Wiring Note

on preceding page

.)

12. Turn power ON.

13. Issue command /1P1000. The motor will move 1000 steps in

the positive direction.

If motor spins without stopping, reverse the CHA and CHB

connections.

You're on your way!

For other commands and hookups,

see the full command set and wiring diagram on our website.

MOTOR -

MOTOR +

GROUND

CHAN B

+5V ENCODER

POWER

CHAN A

INDEX

CAUTION!

Always turn off power before

connecting or disconnecting

motor to avoid damaging

circuit board.

NOTE: If you send your

motor to us, we will be

happy to work out the

correct Hall sensor

phasing for you.

CAUTION!

Always turn off power before

connecting or disconnecting

motor to avoid damaging

circuit board.

NOTE

On SV17, Hall Sensor

power is +15V. If +5V is

needed, obtain from

encoder connector pin 4.

Motor Tuning (BLDC motors)

If motor behavior is oscillatory:

Increase the value of the differential gain constant, for

example /1y3000R.

If oscillatory behavior continues, motor is noisy, and

encoder ticks can be heard, reduce both the proportional

and the differential constants until satisfactory

performance is obtained. For example, /1w250y500R

works well, especially with high (4000) line-count

encoders.

(The larger the line count, the smaller the w, x, and y

values.)

1

1

2

2

3

3

Hall Sensor Phasing (BLDC motors)

This is a trial-and-error method for finding the correct

hookup for your Hall sensor. (The correct hookup for

many Hall sensors can be found in the EZSV17 or

EZSV23 wiring diagram on our Web site.)

NOTE: For Hall sensor phasing by trial

and error, you MUST use a current-limited

lab supply set to the lesser value of 1/2A or

1/4 of the maximum current rating of the motor.

1. With power OFF and the encoder disconnected,

wire Hall sensors to pins 1, 2, and 3 in any order.

2. Set the current limit low by issuing command

/1m30R.

3. Do the following as you try each of the 6 possible

wiring combinations (123,132, 213, 231, 312,

321): ALWAYS DISCONNECT POWER BEFORE

CHANGING WIRES

Issue command /1A1000R. The motor

should spin smoothly in one direction for

about 5 seconds and stop

.

While the motor spins, hold its shaft lightly

and observe any "dead spots" that you feel.

DO THIS ONLY IF YOU CAN DO IT SAFELY!

Four combinations will produce dead spots or

positions at which the rotor locks.

One combination will produce dead spots or

positions at which the rotor locks that are less

obvious.

One combination will produce very smooth motion

with no dead spots or rotor locking points.This is

the correct wiring combination for your Hall

sensors.

NOTE: Don't switch power wires to the motor;

only switch Hall sensor wires.

All Motion

www.allmotion.com

5501 Del Oro Court, San Jose, CA 95124 Telephone 408.460.1345 Email

E Z S t a r t

Hall

Sensors

1

2

3

4

5

6

7

8

Motor

Use for

motors 3A

or higher

on SV23

HALL C

HALL SENSOR POWER

HALL SENSOR GROUND

PHASE A DRIVER

HALL A

HALL B

PHASE C DRIVER

PHASE B DRIVER

PHASE A DRIVER

PHASE C DRIVER

PHASE B DRIVER

Starting up