The Specialist In Drum Handling Equipment

Model 82AM-GT

Mobile-Karrier / Palletizer with Geared Tilt

and Spark Resistant Parts

operator’s Manual for Model 82AM-GT Morse Mobile-Karrier / Palletizer

Serial number 0315 to ____ (MMYY)

morsedrum.com

Copyright 2019 - Morse Mfg. Co., Inc.

Form OM82AM-GT (0315-____) (Updated 12 Jun, 2019 9:35 AM)

3

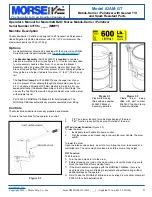

Machine Description

The Mobile-Karrier / Palletizer is designed to lift, transport, and dispense a

ribbed 55-gallon (208 liter) steel drum with 22.5” (57.2 cm) diameter. The

maximum capacity is 600 Lb. (272 kg).

options

A smaller diameter drum can be handled with the correct size 55/30M

•

Series Diameter Adaptor installed (see

Diameter Adaptor literature

).

The

•

Bracket Assembly

(Part # 4556M-P) is

required

to handle a

plastic drum without a top rim (see figure 2.1). It is also recommended

to more securely handle a fiber drum. You can use the Bracket

Assembly with a 55-gallon (208 liter) plastic, steel or fiber drum. The

brace at top and bottom of the drum prevent it from slipping lengthways

through the drum holder. It adjusts for a drum 31” to 37” (79 to 94 cm)

tall.

The

•

Top Rim Clamp

(Part # 4560M-P) grips the upper rim of your

drum to prevent it from slipping through the drum holder (see figure

2.2). To handle a 55-gallon (208 liter) plastic drum with top rim, you

must

install either the Bracket Assembly or the Top Rim Clamp. You

can use the Top Rim Clamp with a 55-gallon plastic, steel or fiber drum

with suitable top rim.

Part # 3900-P MORStop Tilt-Brake Kit for field installation. The

•

MORStop Tilt-Brake automatically prevents unwanted drum tilting.

Controls

The Morse Mobile-Karrier is manually propelled and steered.

There are two functions for the operator to control:

“LIFT” and lower function for vertical positioning of the drum

1.

“TILT” function to control the degree of rotation of the drum

2.

LIFT and Lower Function

(Figure 2.3)

To raise the drum

Insert pump lever handle into pump socket.

1.

With the release valve closed, begin to pump the lever handle. The drum

2.

will lift.

To lower the drum

Open the release valve slowly, a part of a turn. Allow the drum to descend at a

controlled rate. The valve may be reclosed to hold the drum at any height.

TILT Function

To tilt the drum

Turn the hand crank to turn the drum.

1.

Before releasing your grip on the hand crank, pull out the crank stop pin to

2.

block the hand crank from spinning freely.

If the drum handler is equipped with the MORStop Tilt-Brake, there is no

3.

need to use the stop pin. Braking is immediate and self-actuating, without

additional steps by the operator.

Note: To add the MORStop Tilt-Brake to an existing drum handler, order part

4.

# 3900-P for a field installation kit.

Figure 2.2

Plastic

drum

being

lifted with part number

4560M-P Top Rim Clamp

Assembly installed.

Figure 2.1

Plastic drum being

lifted with part number

4556M-P Bracket

Assembly installed.

Figure 2.3