The Specialist In Drum Handling Equipment

201 Series

Portable Drum Rollers

operator’s Manual for Morse 201 Series Portable Drum Rollers

Serial number 286584 to ______

morsedrum.com

Copyright 2019 - Morse Mfg. Co., Inc.

Form OM201 (286584-______)

(Updated 22 Jul, 2020)

3

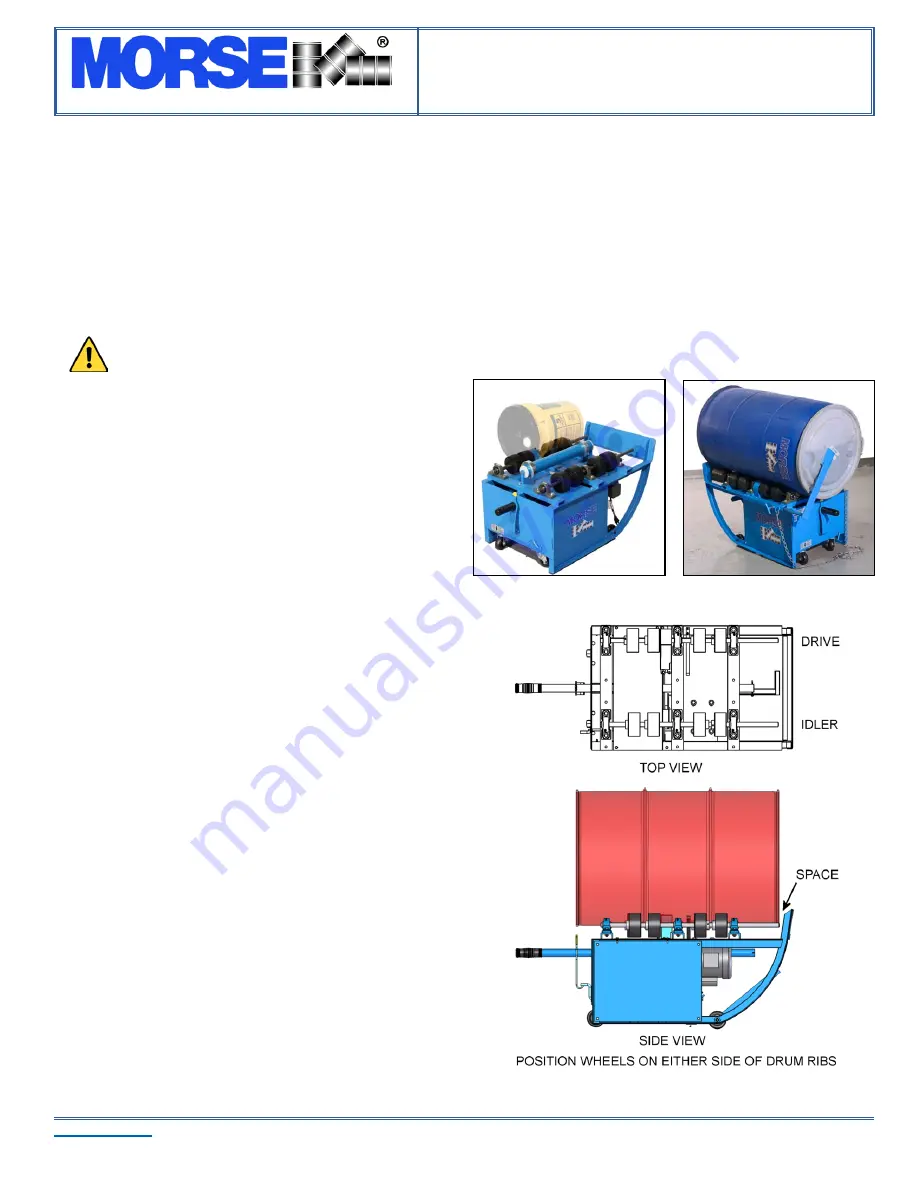

Machine Description

The 201 Series Drum Rollers are designed to roll a steel drum, 6” to 28” (15.2 to 71.1 cm) in diameter, and up to 37” (94 cm) long.

Fixed speed models roll a 22.5” (57.2 cm) diameter drum at 20 RPM.

•

The 201VS Series has Variable Speed from 15 to 24 RPM. The drum rotation speed is based on a 22.5” (57.2 cm) diameter

•

55-gallon (210 liter) steel drum and a 60 Hz, 1725 RPM motor. The drum rotation speed decreases with a 50 Hz motor.

Capacity:

The maximum liquid load capacity rating is 500 Lb. (227 kg).

•

Dry load capacity is 300 Lb. (136 kg).

•

WARnInG -

DO NOT exceed these ratings. Exceeding these ratings or handling a drum other than those mentioned above

is unsafe and could result in equipment damage,

excessive wear, motor overload and shortened service

life of transmission components.

options

option # 1-5P

•

(top right) - Install this Idler Attachment to roll a

1 to 5 gallon can or pail on a Portable Drum Roller.

A 55-gallon plastic drum can be rotated with the correct POLY

•

option installed.

Order

•

option # PoLY-201

factory installed on your new

201 Series Drum Roller.

Order

•

option # PoLY-201FI

for field installation of POLY

Kit on your existing 201 Series Drum Roller.

Important

Review the Material Safety Data Sheet(s) for the material(s) in

1.

the drum(s) and take all necessary precautions. Safety shoes,

work gloves, hard hat and other personal protective devices are

recommended.

Please read all instructions thoroughly before attempting to

2.

operate your new Morse drum handler.

When loading, unloading, operating, or maintaining your MORSE

3.

drum Roller, always use care and good judgment. Maintain

secure footing and a firm hold. Keep hands and loose clothing

away from all moving parts. Never allow anyone to be below

any part of a raised drum handler or drum. Read operating

instructions and review the pictures in the sales brochure before

operation.

Morse Rollers do not comply with OSHA unless they are installed

4.

in accordance with OSHA subpart O, 1910.212 - “General

requirements for all machines.” Morse Rollers should be installed

in accordance with OSHA requirements for enclosure and

interlock, etc. Power connections and motor controls must comply

with applicable codes.

Prior to initial use, inspect all moving parts. Perform necessary

5.

inspections, operator training, etc.

Figure 1

Option # 1-5P

Option # POLY-201