The Specialist In Drum Handling Equipment

Model 400A-96-110

Hydra-Lift, 96”, AC Power Lift & Tilt

Operator’s Manual for Morse Hydra-Lift Karrier Model 400A-96-110

Serial Number 1210 to ____ (MMYY)

morsedrum.com

Copyright 2022 - Morse Mfg. Co., Inc.

Form OM400A-96-110 (1210-____)

(Updated 2 Feb, 2022)

5

CAUTION

– Do Not Transport with Drum Raised

ALWAYS LOWER THE DRUM HOLDER TO LOWEST POSITION BEFORE TRANSPORTING.

Unit can become unstable when transporting with raised load.

5.) Lift drum to desired pouring height. Operate tilt control as described in

“Machine Description - Controls”

(page 4) to

adjust drum attitude. This is especially important when lifting an open drum. The floor lock should be engaged while

dispensing / draining.

6.) When dispensing is complete, tilt drum back to upright position. Disengage floor lock and lower drum to transporting

height; about 6” (15.2 cm) off floor.

WARNING

- Stay Clear of Raised Drum

NEVER allow anyone to be below any part of raised drum handler or drum. Remain behind

push handle while handling drum.

WARNING

– Do NOT Disengage Cinch Chain When Drum is off the Ground

When drum is in upright position, lower drum to floor before releasing cinch chain.

7.) Push unit to drum storage area and lower to floor in upright position. Release cinch chain from ratchet by applying

pressure to ratchet handle in clockwise direction with one hand and opening pawl to free ratchet with other hand.

Remove cinch chain link from ratchet.

Operating Instructions

1.) Push Hydra-Lift Karrier to drum.

2.) Using the “LIFT” control as described in “

Machine

Description - Controls

” (page 4), position drum holder

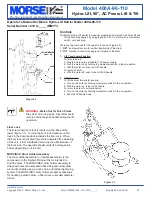

assembly with back band at middle of drum (Figure 3.1).

With ratchet plate swung open and cinch chain hanging

from chain hook, push unit until back band rests firmly

against drum. Some adjustment to tilt angle of saddle

may be necessary to ensure band fits flush on drum.

3.)

Attaching the drum:

Drape chain across front of drum and engage a link into

slot in ratchet (Figure 3.2). Turn ratchet clockwise to

tighten chain. If ratchet turns until pawl is beyond last

ratchet tooth, turn ratchet back and slide next link into

ratchet slot and try tightening again. Chain must be

held tightly against drum with pawl engaged securely in

ratchet teeth.

4.) Operate lift function to lift drum clear of floor. Roll to

dispensing location. NOTE: Do not allow drum to impact

on floor, pouring station, etc. or spill or damage could

occur.

Figure 3.2

START-UP Procedure

Machine is shipped with hydraulic fluid.

1.

Install provided hydraulic control levers (threaded rods with black

ball handles).

2. IMPORTANT:

BEFORE operation, remove the

RED

shipping plug

from the hydraulic reservoir, and replace with the provided

BLACK

breather.