3.3 Wiring

The use of crimp “boot lace ferrules” is recommended for the

screw terminals. Allow sufficient cable length so the circuit

card can be withdrawn from its case with the wires still

connected. This enables switch changes on the circuit card

to be made while the card is still connected and operating.

An extra 100mm, for cables going outside the enclosure,

as well as wires connecting to adjacent DIN rail units,

is adequate.

The screw terminals will accommodate wire sizes from 0.2mm

2

to 2.5mm

2

(24AWG to 12AWG). One Amp rated, 0.2mm

2

should be adequate for all applications.

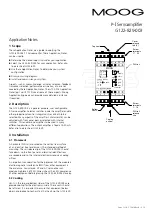

cable gland

100mm Loop

Wires

Enclosure

Radial screen

termination

Cable

Grounded EMI

Preferred Wiring

Page 2 of 6: C70916 Rev B – 4.10

Cable gland

100mm Loop

Cable

Enclosure

Cable

Wire soldered

to screen

Drain wire.

or

(Heat shrink to

cover the screen)

Alternative Wiring

3.4 EMC

The G122-829-003 emits radiation well below the level called

for in its CE mark test. Therefore, no special precautions are

required for suppression of emissions. However, immunity from

external interfering radiation is dependent on careful wiring

techniques. The accepted method is to use screened cables for

all connections and to radially terminate the cable screens, in

an appropriate grounded cable gland, at the point of entry into

the industrial steel enclosure. If this is not possible, chassis

ground screw terminals are provided on the G122-829-003.

Exposed wires should be kept to a minimum length. Connect

the screens at both ends of the cable to chassis ground.

4 Power supply

24V DC nominal, 22 to 28V

75mA @ 24V without a load, 200mA @ 100mA load.

If an unregulated supply is used the bottom of the ripple

waveform is not to fall below 22V.

It is recommended that an M205, 250mA T (slow blow) fuse,

compliant with IEC127-2 sheet 3, be placed in series with the

+24V input to protect the electronic circuit. If terminal 23 is

used to power a proportional valve, the fuse should be

increased to cater for the extra current.

R17

1

2

3

4

spare

enable

dither

4-20mA (feedback input)

P gain range

Input 3 to

output amp

lim

cmd lag

feedback lead

Input 2 to

error amp

R34

R33

R16

SW5

SW4

SW 6

1

2

3

4

spare

PR

INT

E or P

SW5 V or

SW 3

Step P.B.

[SW1]

To access the circuit card switches, the circuit card must be

withdrawn from the case. See paragraph 17.

5 Set-up adjustments

Trimpots are all 15 turns.

Plug-in resistors are all “quarter watt” 1% metal film. Two

suitable types are Beyschlag MBB0207 and Roderstein

MK20207.

The amplifier is shipped in the following default state.

top board switches

SW3

STEP

not applicable

SW4

1

P-E

E

2

CMD LAG

off

SW5

IN 2

V

SW6

1

spare

off

2

PR

on

3

I

Lim

off

4

INT

off

bottom board switch, shown as [ ]

[SW1]

1

spare

off

2

ENABLE

on

3

DITHER

off

4

4-20mA (fdbk)

on

R17: 100k (P gain range 1 to 20)

R34: 100k (input 2 to error amp)

R33: not fitted (input 3 to output amp)

R16: not fitted (feedback derivative)

Feedback gain and zero pots: configured for 4-20mA input

Dither level pot: fully counter clockwise (FCCW)

Scale pot: FCCW

P gain pot: FCCW

I

gain pot: FCCW

Bias pot: 0V

ON

shown in on position

shown in off position

SW1 and 6 switch positions