DISASSEMBLY

1. Loosen jam nut, washer (3700/7500) and thread seal. Screw adjustor out of cylinder

head. Remove thread seal, washer (3700/7500) and jam nut.

2. Thoroughly clean and inspect all parts for wear or damage. Replace with new parts

as required.

RE-ASSEMBLY

NOTE:

MUST BE RE-ASSEMBLED BEFORE CYLINDER HEAD IS MOUNTED TO

CYLINDER TUBE.

1. Install jam nut, washer (3700/7500) and thread seal on adjustor.

2. Screw adjustor into the cylinder head. Thread into head until adjustor is flush with

the inside of the cylinder head (Approx. 6-7 turns).

3. Adjust rotation at test. Turning adjustor clockwise reduces rotation, counter-

clockwise increases rotation.

NOTE:

ADJUSTMENTS SHOULD NOT BE MADE WHILE UNIT IS UNDER PRESSURE. FOR

DUAL RACK UNITS, BOTH ADJUSTORS AT EACH END OF STROKE MUST BE SET

EQUALLY SO END OF STROKE LOAD IS EQUALLY ABSORBED BY (2) CYLINDER

HEADS.

DISASSEMBLY

1. Remove cover screw and cover screw seal.

2. Loosen the adjustable stop-set screw.

3. With cylinder head removed from cylinder tube, the adjustor can be removed by

screwing out towards the inside of the cylinder head with a hex wrench

4. Remove nylon pellet and inspect for wear and damage. Replace with new pellet

if required.

RE-ASSEMBLY

NOTE:

MUST BE RE-ASSEMBLED BEFORE CYLINDER HEAD IS MOUNTED TO

CYLINDER TUBE.

1. Screw adjustor into cylinder head from inside cylinder head face. Screw adjustor in

until flush or below the surface of the cylinder head so rotation can be adjusted

at test.

2. Install nylon pellet and set screw but do not tighten until adjustment is set.

3. Adjust rotation at test. Turning adjustor clockwise reduces rotation, counter-

clockwise increases rotation.

NOTE:

ADJUSTMENTS SHOULD NOT BE MADE WHILE UNIT IS UNDER PRESSURE.

FOR DUAL RACK UNITS, BOTH ADJUSTORS AT EACH END OF STROKE MUST

BE SET EQUALLY SO END OF STROKE LOAD IS EQUALLY ABSORBED BY (2)

CYLINDER HEADS.

4. When adjustment is complete, tighten set screw to lock position.

5. Install cover screw seal and cover screw.

DISASSEMBLY

NOTE:

CYLINDER HEAD MUST BE REMOVED FROM THE CYLINDER TUBE

BEFORE DISASSEMBLY.

1. Remove jam nut.

2. Screw adjustor out of the cylinder head. Remove O-ring and back-up ring from

adjustor head.

3. Thoroughly clean and inspect all parts for wear or damage. Replace with new parts

as required.

RE-ASSEMBLY

NOTE:

MUST BE RE-ASSEMBLED BEFORE CYLINDER HEAD IS MOUNTED TO

CYLINDER TUBE.

1. Install new back-up ring and O-ring on adjustor head making sure the flat of the

back-up ring is on the cylinder head side of the seal groove and the curved side is

toward the O-ring and cylinder tube side. Make sure the O-ring is installed in the

curved portion of the back-up ring.

2. Screw adjustor into the cylinder head from inside of the cylinder head. Screw

adjustor all the way in so rotation can be adjusted at test.

3. Adjust rotation at test. Turning adjustor clockwise reduces rotation, counter-

clockwise increases rotation.

4. Tighten jam nut.

NOTE:

ADJUSTMENTS SHOULD NOT BE MADE WHILE UNIT IS UNDER PRESSURE.

FOR DUAL RACK UNITS, BOTH ADJUSTORS AT EACH END OF STROKE MUST

BE SET EQUALLY SO END OF STROKE LOAD IS EQUALLY ABSORBED BY (2)

CYLINDER HEADS.

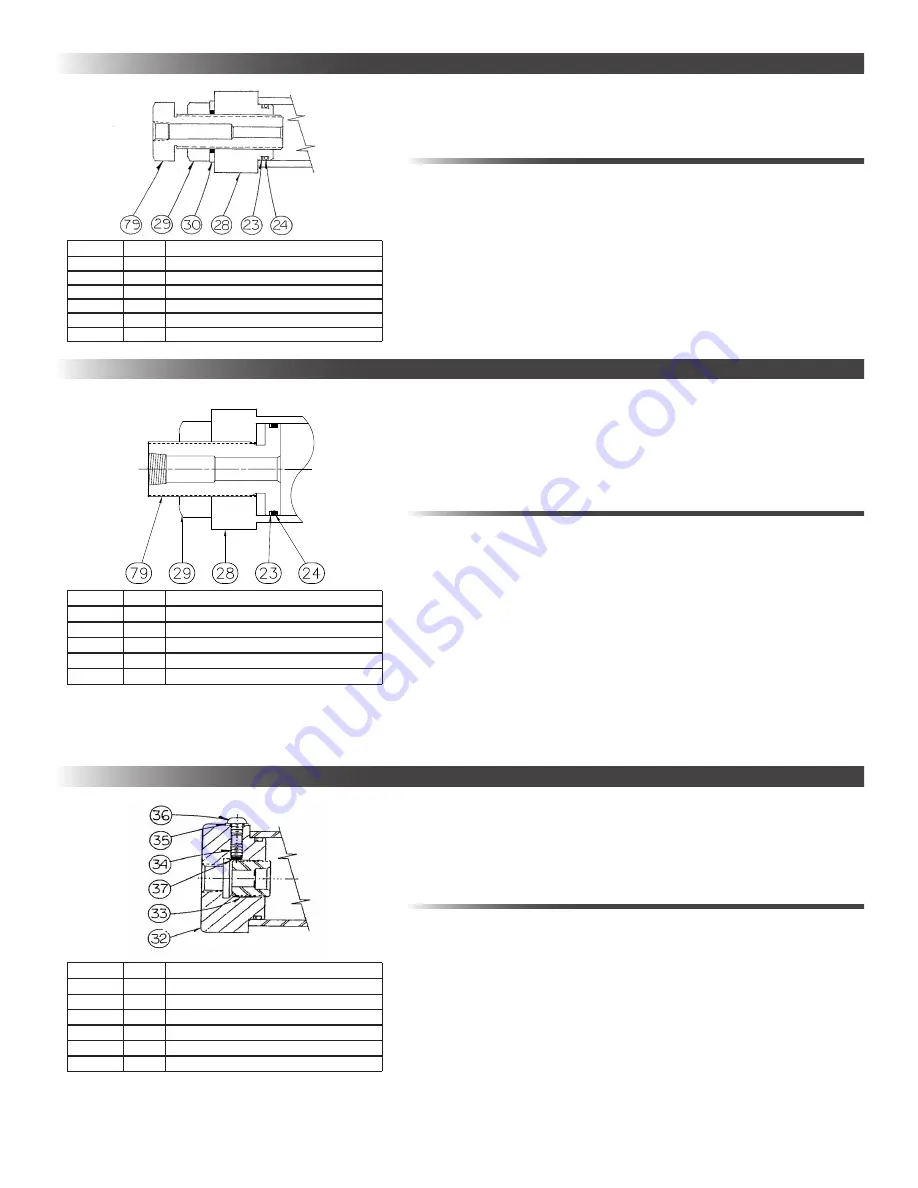

0° TO 30° EXTERNAL ADJUSTABLE STOPS (MODELS 900-7500)

0° TO 5° INTERNAL ADJUSTABLE STOPS (MODELS 3700-30,000)

0° TO 30° EXTERNAL ADJUSTABLE STOPS (MODELS 15,000 & 30,000)

ITEM

QTY

PART NAME

23

1

BACK-UP RING

24

1

O-RING

28

1

EXTERNAL ADJUSTOR, CYLINDER HEAD

29

1

JAM NUT

30

1

THREAD SEAL

79

1

EXTERNAL ADJUSTOR, FIXED CUSHION

ITEM

QTY

PART NAME

32

1

CYLINDER HEAD

33

1

0

O

TO 5

O

INTERNAL ADJUSTABLE STOP

34

1

SET SCREW - ADJUSTABLE STOP

35

1

THREAD SEAL - COVER SCREW

36

1

COVER SCREW

37

1

NYLON LOCKING PELLET

ITEM

QTY

PART NAME

23

1

BACK-UP RING

24

1

O-RING

28

1

EXTERNAL ADJUSTOR, CYLINDER HEAD

29

1

JAM NUT

79

1

EXTERNAL ADJUSTOR, FIXED CUSHION