Moog Inc., East Aurora, NY 14052-0018

Telephone: +1-716-652-2000

Fax: +1-716-687-7910

Toll Free: +1-800-272-MOOG

www.moog.com/industrial

©2018 Moog Inc. All changes are reserved.

CDS6857 500-489 RevG 0818

TJW

Moog is a registered trademark

of Moog Inc. and its subsidiaries. Unless expressly indicated, all trademarks as indicated herein are the

property of Moog

Inc. and its subsidiaries. For disclaimers, see w

w

w

.moog.com/literature/disclaimers.

1. INTRODUCTION

This manual provides the instructions and procedures necessary to install,

operate, and troubleshoot the Moog 78N and 760N series servo valves. The

78N and 760N series servo valves are electro hydraulic equipment for hazardous

locations requiring explosion proof protection. The approved hazardous location

markings include:

II 2 G Ex d IIA T3 Gb KEMA 02ATEX2322 X,

0344 per ATEX directive 2014/34/EU

Ex d IIA T3 Gb IECEx DEK 13.0029X

per IECEx certification scheme.

The 78N and 760N series servo valves are also approved by CSA and TIIS

for hazardous locations. They are intended for directional, position, velocity,

pressure, or force control in hydraulic control systems that operate with mineral

based fluids, or others upon request.

2. OPERATION

The Moog 78N and 760N Series Industrial Servo valves consist of a polarized

electrical torque motor and two stages of hydraulic power amplification. The

motor armature extends into the air gaps of the magnetic flux circuit and is

supported in this position by a flexure tube member. The flexure tube acts as a

seal between the electromagnetic and hydraulic sections of the valve. The two

motor coils surround the armature one on each side of the flexure tube.

The flapper of the first stage hydraulic amplifier is rigidly attached to the

midpoint of the armature. The flapper extends through the flexure tube and

passes between two nozzles, creating two variable orifices between the nozzle

tips and the flapper. The pressure controlled by the flapper and nozzle variable

orifice is fed to the end areas of the second stage spool.

The second stage is a conventional 4-way spool design in which output

flow from the valve, at a fixed valve pressure drop, is proportional to spool

displacement from the null position. A cantilever feedback spring is fixed to

the flapper and engages a slot at the center of the spool. Displacement of the

spool deflects the feedback spring which creates a force on the armature/flapper

assembly.

Input signal induces a magnetic charge in the armature and causes a

deflection of the armature and flapper. This assembly pivots about the flexure

tube and increases the size of one nozzle orifice and decreases the size of the

other.

This action creates a differential pressure from one end of the spool to

the other and results in spool displacement. The spool displacement transmits a

force in the feedback wire which opposes the original input signal torque. Spool

movement continues until the feedback wire force equals the input signal force.

CAUTION

DISASSEMBLY, MAINTENANCE, OR REPAIR OTHER THAN IN ACCORDANCE WITH THE

INSTRUCTIONS HEREIN OR OTHER SPECIFIC WRITTEN DIRECTIONS FROM MOOG WILL

INVALIDATE MOOG’S OBLIGATIONS UNDER ITS WARRANTY AND YIELD THE EXPLOSION

PROOF PROTECTION PERMIT NULL AND VOID.

78N/760N Series Installation

and Operation Instruction

Electrohydraulic Servo Valve

Explosion Proof

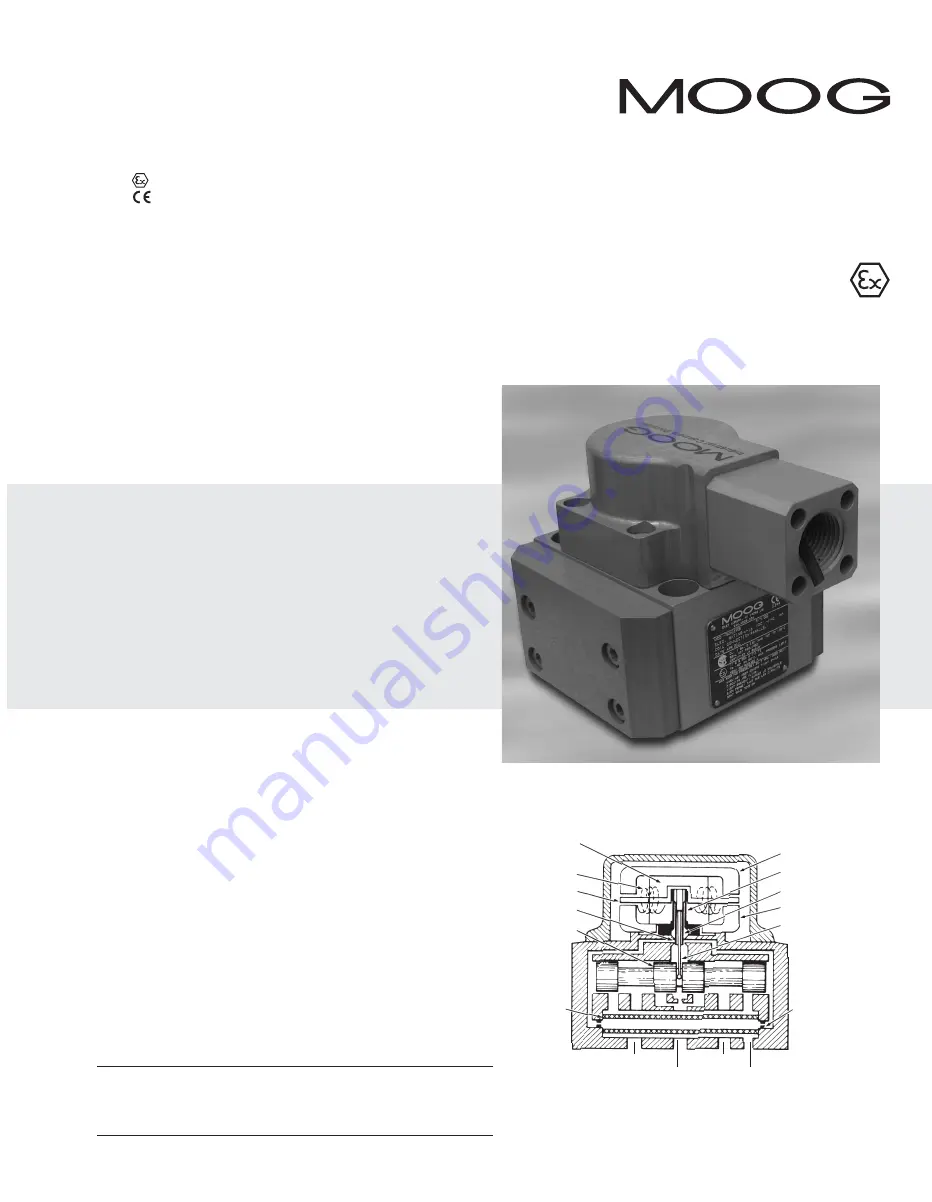

ELECTROHYDRAULIC VALVE CUT-AWAY

Figure 1 Moog Series 760N

Upper Polepiece

Flexure Tube

Flapper

Lower Polepiece

Feedback Wire

Inlet Orifice

Magnet

Coil

Armature

Nozzle

Spool

Control Port B

Tank

Control Port A

Pressure

Filter

(760N shown)