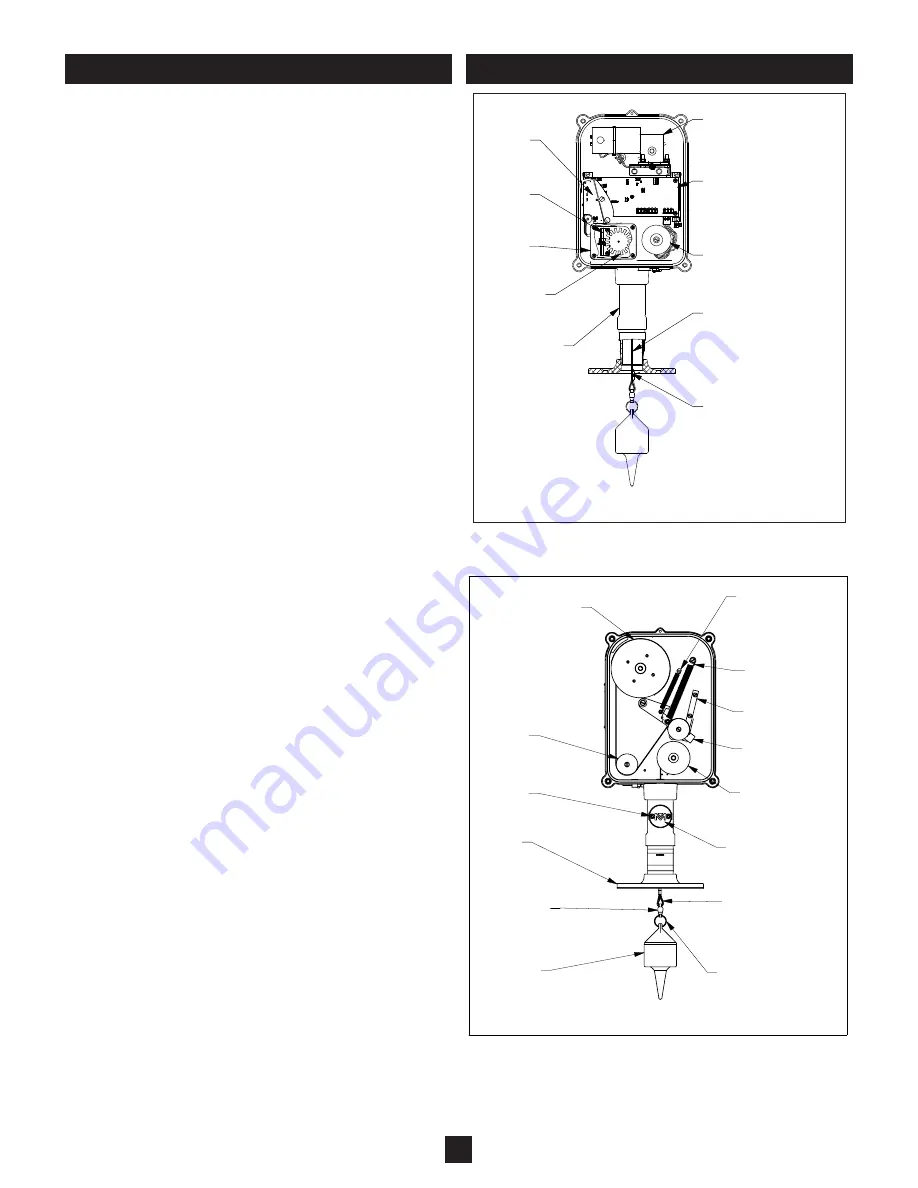

COVER SCREWS

(6-0052)

COVER ASSY

(6-3257)

MOTOR ASSY

(6-1162)

MODULES

SMART, 115V (6-8033)

SMART, 230V (6-8043)

4~20,

115V (6-8036)

4~20,

230V (6-8046)

STANDPIPE ASSY

(6-3258)

CODEWHEEL

(6-3112)

COVER,

OPTICS BOX

(6-4007)

OPTICAL

ENCODER

(6-8031)

SWING ARM

SENSOR

(6-8034)

TRANSFORMER ASSY

(230VAC MODELS ONLY)

(6-1152)

CABLE

NYLON-JK (R0321-002)

UNJKT SS (R0421-001)

POLY-JKT (R0321-003)

COMPRESSION SLEEVE

FOR UNJKTED (6-0047)

FOR JKTED (6-0064)

WIPER SEALS

VITON (6-2094)

BRUSH (6-2095)

FLANGE

(6-0086)

SPLIT RING FASTENER

CABLE THIMBLE

(6-0065)

(6-0055)

(6-3103)

PLUMB BOB

WIPER SEAL

STORAGE REEL ASSY

(6-3220)

(6-2087)

ROLLER

(6-3204)

CABLE SWIVEL

WHEEL ASSY

(6-3229)

SWING ARM ASSY

(6-0051)

TAKE-UP SPRING

(6-0056)

WEAR PLATE

(6-2075)

COVER SCREWS

MEASURING

INTENSIFIER SPRING

(6-0057)

SMU Replacement Parts (Electrical Side)

SMU Replacement Parts (Mechanical Side)

PROBLEM: The SMU will not make a measurement (take a

sounding)

CAUSE/SOLUTION:

1. (All models) Lock-out feature is “active”. Remove "lock-out"

signal from the lock-out terminal block.

2. (RS-485) The address of the SMU and the operator inter-

face channel do not match, or there are multiple SMUs with

the same address. Create a unique address for each SMU

on the network and ensure they match-up with a operator

interface channel #.

3. (RS-485) The network termination switches are improper-

ly set. Verify that only the devices on the physical ends of

the network have the network termination switches “ON”,

and all others are “OFF”.

4. (Analog) The automatic timer is not activated. Verify that

the parameter AutoTime is “ON” if automatic measurement

cycles are desired.

PROBLEM: The SMU reports an “Error” after a measure-

ment cycle is completed

CAUSE/SOLUTION:

1. (Return Error) The plumb bob did not travel as far when

ascending as it did when descending. Determine if plumb

bob is trapped in material. Request another measurement.

A subsequent “motion” error confirms an entrapment. A

subsequent “index” error indicates that plumb bob has

freed itself. Request another measurement and errors will

likely cease.

2. (Index Error) The plumb bob did not travel as far when

descending as it did when ascending. Determine if mount-

ing is causing the plumb bob to return to an inconsistent

location at the start/socket position.

3. (Motion Error) The plumb bob did not travel a far

enough distance when measurement was requested.

Consider the following possibilities:

- Plumb bob is trapped in material

- Plumb bob is stuck to mounting surface

- Cable is broken

- Cable is restricted in wiper seal

- Cable is damaged

PROBLEM: The plumb bob gets stuck in the socket

CAUSE/SOLUTION:

1. Material build-up may be causing plumb bob to “cling” to

the socket. Turn “ON” the Descend-Assist feature through

the ConfigureSensor app in the MISC SETTINGS section.

See Pg. 10 (RS-485) or Pg. 13 (Analog) of this document.

PROBLEM: The SMU measurement is not accurate

CAUSE/SOLUTION:

1. Cable length is too short for application. Replace cable

with suitable length.

2. Wiper seals are creating excessive drag resulting in pre-

mature reversing of plumb bob. Clean or replace

wiper seals.

3. Cable is slipping on measuring wheel due to the lubricity of

the material being measured. Consult factory.

4. Cable is damaged (kinked, frayed) somewhere through its

length resulting in premature reversing of plumb bob.

Replace cable.

5. Cycle Limit function CycLimit is causing plumb

bob to reverse before reaching material surface.

Configure CycLimit value to suit application.

TROUBLESHOOTING

MECHANICALS

16

COVER ASSY

6-3257 (HAZARDOUS LOC)

6-3259 (ORDINARY LOC)

COVER ASSY

(6-3257)

COVER SCREWS

(6-0052)

(6-0047)