FineAdjust Applicator

Doc. No: TM-638004900

Release Date: 09-04-03

UNCONTROLLED COPY

Page 46 of 50

Revision: G

Revision Date: 01-15-13

B.1 Crimp Process Control

The crimp process is the interaction of a terminal, wire,

tooling, personnel, methods and procedures, and

environmental attributes that, when controlled, produce a

quality termination. Quality control is an important aspect

of quality crimping. It should not take excessive setup or

inspection time to implement, and can save a harness

manufacturer thousands of dollars in potential rework or

re-manufacturing.

The key to quality is to target nominal specifications while

continuously reducing variability. Achieving target is

determined by the adjustability of the tooling. The

FineAdjust applicator allows crimp height adjustment to

.005mm (.0002”) of target.

Variability is the slight changes that occur from crimp to

crimp. There are two types of variability, common and

special. Common sources of variation are those causes

that affect the process uniformly, and are created from

numerous small sources. Common variability is inherent

tolerances within a reel of wire or terminals. In addition,

common variability is created by the natural tolerances of

the stripping and crimping machines. Reduction of

variability at the common level normally has to come from

changes at the wire, terminal, and tooling manufacturer.

The second source of variability is referred to as special

cause. Unlike common cause, special sources of

variation occur irregularly and unpredictably. Without

checks throughout a run, a tool becoming loose after the

first hundred crimps, or a damaged tool from a jam, may

be undetected until thousands of crimps are made.

This section assumes that crimp height is being

measured with a resolution of .0025 mm (.0001”), and

pull force is measured with a resolution of 1 N (.25 lbf).

B.2 Process Capability

Molex qualifies each FineAdjust Applicator design for pull

force and crimp height.

This qualification is performed on a common wire

stranding, and is targeted at 2.0 C

pk

. Before a new

crimping tool is put in production, it is recommended that

the customer using their specific wire in their process

should do a capability study. A capability study is based

on the assumption of a normal distribution (bell-type

curve). It provides an estimate on the probability of a

measurement being outside of specification.

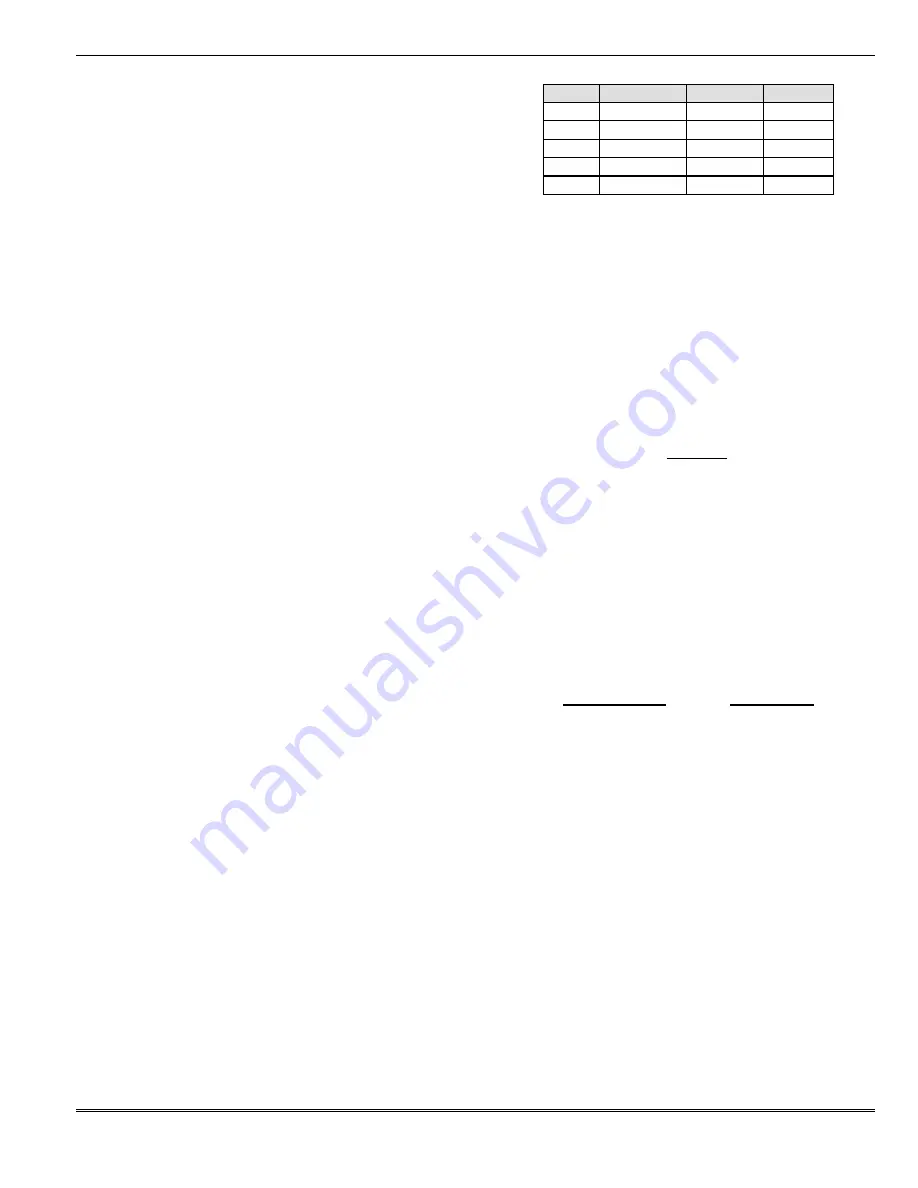

C

pk

+/- Sigma

% Yield

PPM

0.67

2

95.45

45,500

1

3

99.73

2,699

1.33

4

99.99

63

1.67

5

99.99+

0.57

2

6

99.99++

0

PPM - Parts per million – number of potential defects

per million crimps produced.

A minimum of a 25-piece sample should be run off

the crimping process. The average and standard

deviation should be calculated for each specification.

A capability index (C

p)

is defined by the formula

below. C

p

may range in value from 0 to infinity, with

a larger value indicating a more capable process. A

value greater than (>) 1.33 is normally considered

acceptable.

Tolerance

6*Standard Deviation

The C

pk

index indicates whether the process will produce

units within the tolerance limits. C

pk

has a value equal to

C

p

if the process is centered on the mean of specification;

if C

pk

is negative, the process mean is outside the

specification limits; if C

pk

is between 0 and 1 then some of

the 6 sigma spread falls outside the tolerance limits. If

C

pk

is larger than 1, the 6 sigma spread is completely

within the tolerance limits. C

pk

is calculated with the

lesser of the following formulas:

(USL - MEAN) (LSL - MEAN)

3*Standard Deviation 3*Standard Deviation

USL = Upper Specification Limit, LSL = Lower

Specification Limit

Six sigma is a goal of many companies because it

represents virtually zero defects. The ability of a

company to achieve a six-sigma level is dependent on

the amount of common variability in their process. Hand

stripping of the wire will produce more variability than a

stripping machine.

A crimping hand tool will produce more variability than a

press and die set. Bench terminations will produce more

variability than a wire-processing machine.

A portion of the variability in crimping will come from what

instruments are used to measure the parts and the ability

of an operator to repeat the measurement. A crimp

micrometer will measure more accurately than a dial

caliper. An automatic pull force system will measure