Quality Crimp Handbook

Order No 63800-0029

Release Date:09-04-03

UNCONTROLLED COPY

Page 17 of 24

Revision: B

Revision Date: 10-07-05

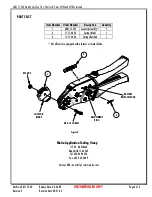

Bell Mouth and Cut-off Tab Length

Symptom

Cause

Solution

Excessive bell mouth, no cut-off tab

Adjust track position for small cut-off tab

Low pull force

(Figure 9-6 and 9-7)

Excessive bell mouth, cut-off tab alright

Check for worn or incorrect punch tooling and replace

Adjust track position

Cut or nicked strands

(Figure 9-8)

No bell mouth and/or excessive cut-off tab

Check for camber in terminal strip

Check for worn cut-off and replace if necessary

Long cut-off tab (Figure 9-9) Good bell mouth and excessive cut-off tab

Check for worn punch tooling, replace, and re-adjust track

Conductor Brush and Insulation Position

Symptom

Cause

Solution

Insulation under conductor crimp, good

conductor brush (Figure 9-10)

Strip length too short

Check specification, adjust strip length longer

Bench - Wire stop position incorrect

Adjust wire stop to center of transition area

Insulation under conductor crimp, long

conductor brush length (Figure 9-11)

Wire Processing – Press position incorrect

Adjust press position away from wire

Check specification, adjust strip length longer

Insulation under conductor crimp,

short or no conductor brush (Figure 9-12)

Strip length too short

Re-adjust wire stop position for bench applications OR

re-adjust press position for wire processing applications

Check specification, adjust strip length shorter

Strip length too long

Re-adjust wire stop position for bench applications OR

re-adjust press position for wire processing applications

Insulation edge centered in transition area,

conductor brush too long (Figure 9-13)

Irregular wire cut-off or strands pulled

from insulation bundle

Check for worn stripping tooling

Check specification, adjust strip length longer

Insulation edge centered in transition area,

conductor brush too short (Figure 9-14)

Strip length too short

Re-adjust wire stop position for bench applications OR

re-adjust press position for wire processing applications

Check specification, adjust strip length shorter

Insulation edge under insulation crimp,

good or long conductor brush (Figure 9-15)

Strip length too long

Re-adjust wire stop position for bench applications OR

re-adjust press position for wire processing applications

Bench - Wire stop position incorrect

Adjust wire stop to center of transition area

Wire processing - Press position incorrect

Adjust press position away from wire

Insulation edge under insulation crimp,

short or no conductor brush (Figure 9-16)

Verify operators wire placement ability

Operate training, reduce crimping rate

Figure 9-5

OPTIMAL CRIMP

Figure 9-6

EXCESSIVE BELL MOUTH

Figure 9-7

EXCESSIVE BELL MOUTH, NO CUT-OFF TAB

Figure 9-8

NO BELL MOUTH, EXCESSIVE CUT-OFF TAB

Figure 9-9

EXCESSIVE CUT-OFF TAB, GOOD BELL MOUTH