User Instructions

Should you find your equipment is no longer of use,

please dispose of in a responsible manner. Please

contact Modulift if you need further guidance

© Copyright 2017 Modulift.

All rights reserved.

MOD CLS

MOD CLS US JULY 2017

Assembly Procedure

●

●

Each lifting beam clamp will be supplied fully assembled.

Individual clamps are not to be dismantled.

●

●

Remove stopper bolts and push each lifting beam clamp

through the open-end section of the beam, ensuring that

the lug plate is orientated the correct way as shown in

Fig. 4

●

●

Replace stopper bolts and nuts on top and bottom flanges

at each end of the beam. Tighten to a torque of 30 lbf.ft

●

●

For additional safety, always ensure the

red locking bolt

on each clamp is tightened to a torque of 30 lbf.ft and the

clamp is secure, once in the correct position on the beam

for your desired lifting configuration.

●

●

Always fit at least one

red safety stop

to each clamp (see

Fig.

3

). Tighten bolt to a torque of 30 lbf.ft before lifting. For ease

of visibility, fit all

red safety stops

to one side of the beam

●

●

Always ensure the 6.5t Lifting Beam Clamps are fitted to

the top of the beam and the 4.75t Lifting Beam Clamps are

fitted to the bottom of the beam.

●

●

If in any doubt please contact Modulift.

Do’s & Don’ts

●

●

Always have the safety stopper bolts or studs tightened with

nuts on both top and bottom flanges and at both ends of the

beam before commencing any lifts.

●

●

Do not hang any loads directly from the beam section, always

lift from shackles on the beam clamps.

●

●

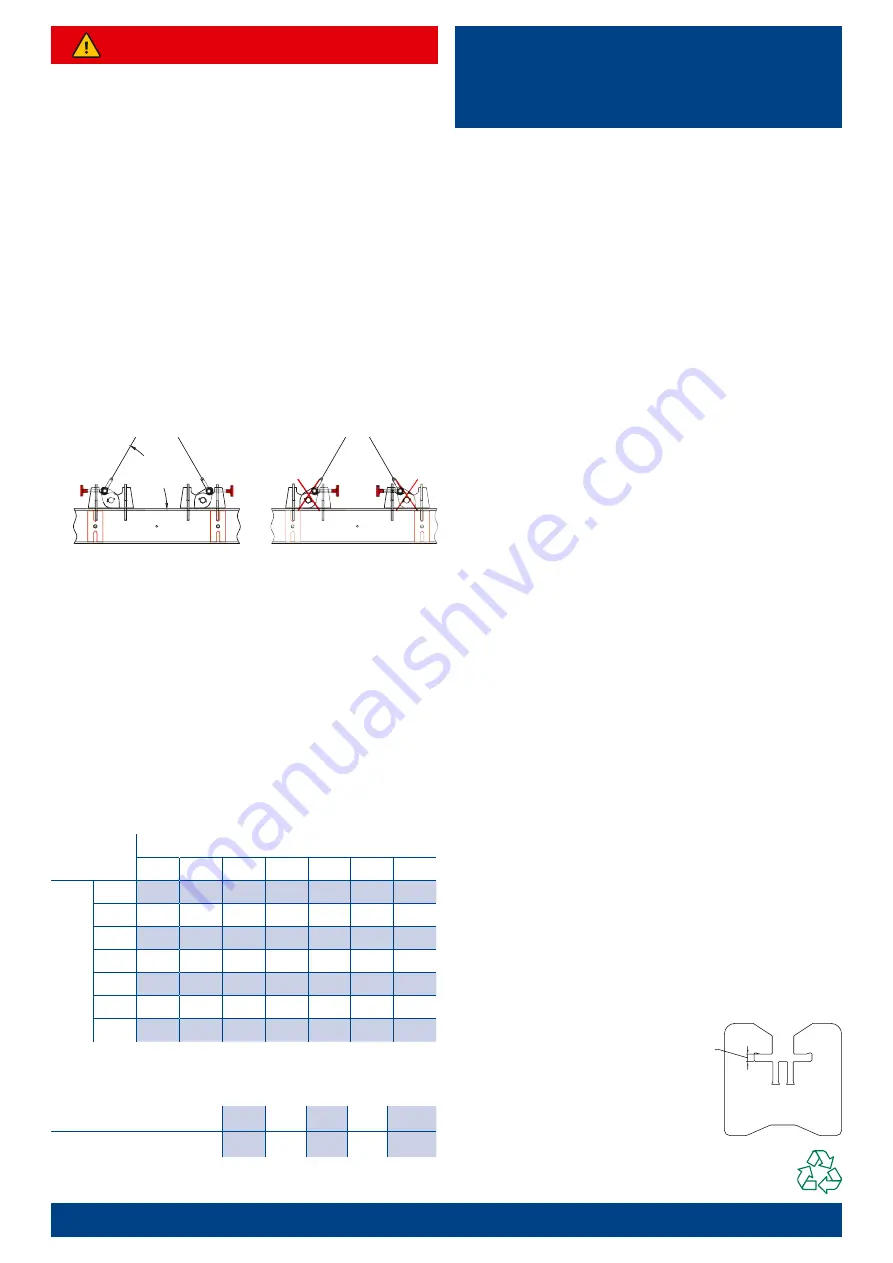

Do ensure that the clamp lug plate is always being pulled

towards the body of the clamp, never away from the body of

the clamp (see

Fig. 4

and

Fig. 5

).

●

●

Do ensure the

red locking bolt

on each clamp is tightened

to a torque of 30 lbf.ft prior to any lift.

●

●

Do ensure at least one

red safety stop

is fitted to each clamp

(see

Fig. 3

). For arrangement (iii)

Fig.3

, always check

red

safety stop

is attached to the nearest beam hole to the clamp.

Tighten bolt to a torque of 30 lbf.ft prior to any lift. For ease of

visibility, fit all

red safety stops

to one side of the beam

●

●

Do ensure that the lift is stable. Never carry out unstable lifts.

●

●

Do ensure that the load and the beam (either loaded

or unloaded) both lift level by positioning the bottom

clamps in the correct location (depending on clamp lug plate

orientation, a maximum of 6 degrees of tilt is permitted).

●

●

Never stand beneath the suspended load or lifting beam

(either loaded or unloaded).

●

●

Do ensure that the beam flange and the clamps are free of

grease or excessive water where they clamp together.

●

●

Check that there is no

deformation or distortion

on the clamps before any

lift. In case of deformation or distortion,

the relevant part must be discarded and

replaced. Always check and ensure

that the arms of the collar plates are

parallel and not deformed (refer to

Fig. 6

).

Check collar

plate arms are

parallel and

not deformed

Fig. 6 – Collar plate

WARNING!

●

●

Personnel using this system should be suitably trained,

competent and have a clear understanding of Safe

Slinging procedures.

●

●

The use of Modulift equipment must be in accordance with

the procedures laid down in ‘ASME B30.20 – 2013’.

●

●

Never exceed stated beam WLL

(adhere to

Table 3

WLL for

configuration used) or clamps WLL (see MOD CLS specification).

●

●

The top sling length is critical to the safe use of the beam

when used on the semi-spreader configuration.

Do not

have less than 60° BSA sling angles

.

●

●

Ensure that clamp lug plates are always being pulled

towards the body of the clamp (as shown in

Fig. 4

), never

away from the body of the clamp (as shown in

Fig. 5

).

Always ensure the

red locking bolt

on each clamp is

tightened to a torque of 30 lbf.ft before lifting.

●

●

Always fit at least one

red safety stop

to each clamp (see

Fig.

3

). Tighten bolt to a torque of 30 lbf.ft before lifting. For ease

of visibility, fit all

red safety stops

to one side of the beam.

●

●

Ensure that the beam is lifting level whenever possible.

Never allow the beam to tilt more than 6 degrees from

the horizontal plane

(Please refer to LEEA COPSULE). In

case of tilt, ensure that the clamp lug plates are orientated

so that the tilt angle pulls the clamp lug plate towards the

body of the clamp, never away from the body of the clamp.

●

●

Always ensure that the lift is stable. Please note that for a

lifting beam configuration the height increment between

beam pivoting points shall not exceed 19.7

"

, as shown in

Fig. 2

(1 top lug). If in any doubt please contact Modulift.

Modulift UK Ltd

tel:

011 44 1202 621511

email:

www.modulift.com

Page 2 of 4

Table 3 – WLL v Span (in metric tons)

Semi-Spreader configuration (2 top lugs, Fig. 1)

Lifting Beam configuration (1 top lug, Fig. 2)

WLL (t)

A – Top Clamp Span (ft)

<1½

3

6½

10

13

16

19½

B – B

ott

om Span (f

t)

<1½

8.5

8

7

3.5

2

1.25

0.8

3

8

8.5

8

4.5

2.5

1.5

0.9

6½

7.5

8

8.5

7

3.25

1.75

1

10

4.25

5.5

8

8.5

5.25

2.5

1.25

13

2.25

3

4.5

8

8

4

1.75

16

1.25

1.75

2.25

3.75

7

7.5

2.5

19½

0.9

1

1.25

2

2.75

4.25

5.25

If your exact spans are not noted in the table, then please round the

spans up or down to the values that will give you the lowest SWL.

Contact Modulift if you need a specific WLL value for a specific span or

arrangement not covered on the tables above.

B – Bottom Span (ft)

≤ 6½ ≤ 10 ≤ 13 ≤ 16 ≤ 19½

WLL (in metric tons)

6.2

3.75

2.25

1.25

0.8

Fig. 4 – Correct orientation

of lug plates

Fig. 5 – Incorrect orientation

of lug plates

60°

Minimum