5-565.1

19

oPtions

b) Two-stage Electronic Type Thermostat - Includes a

factory installed discharge air sensor. The thermostat

body is field installed remotely and includes the discharge

air set point adjuster that must be field set. Refer to

Literature 5-577 latest revision.

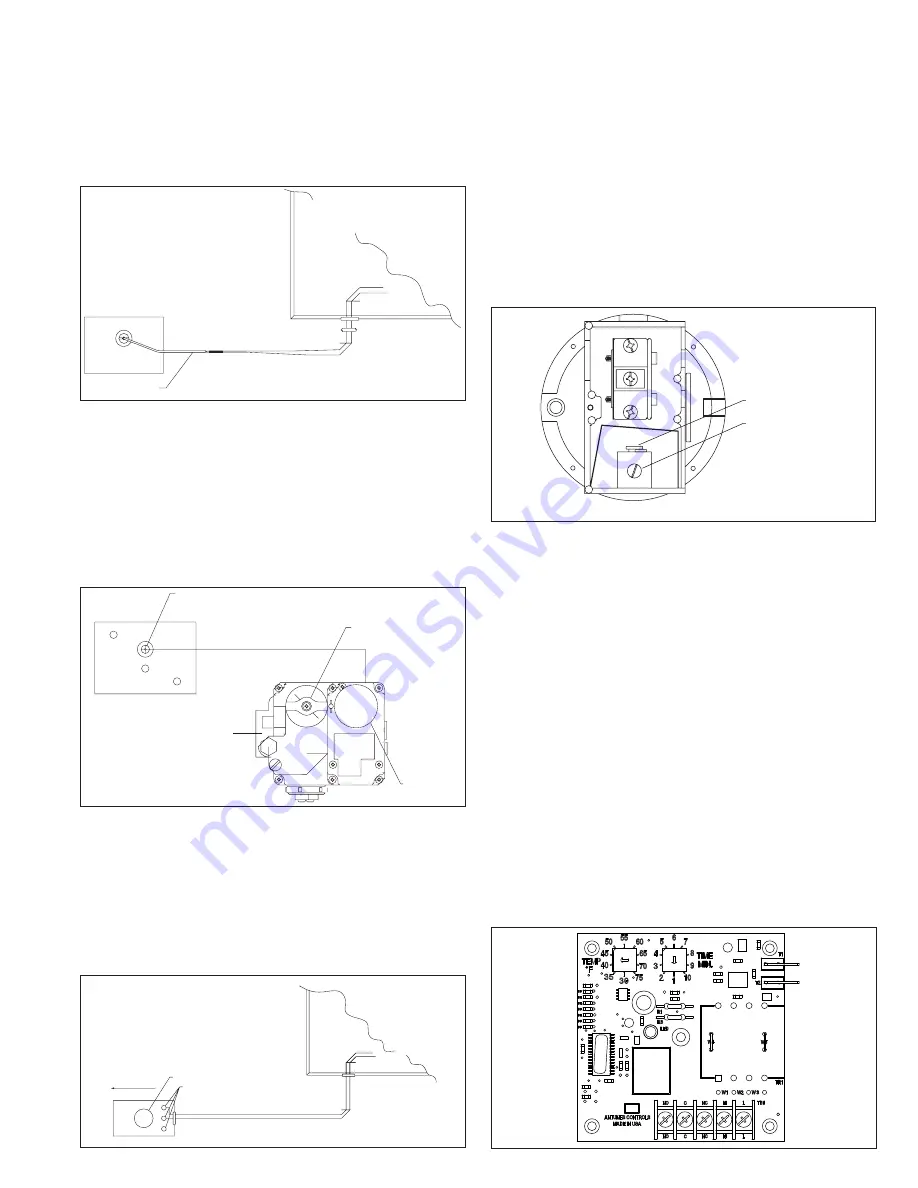

figure 19.1 - two-stage electronic type thermostat sensor

c

) Mechanical Modulating Sensing Bulb - The mechanical

modulating valve includes a hydrostatic sensing bulb that

is factory installed in the discharge air stream for cooling

package units. For blower package units the sensing

bulb is temporarilly afixed to the side of unit to be field

installation in duct work. The discharge air temperature

is field set by the control dial on the modulating gas

valve. Refer to Control Operating Sequence - Mechanical

Modulating Gas Controls for set point temperatures.

figure 19.2 - mechanical modulating sensing Bulb

d)

Electronic Modulating Discharge Air Thermostat –

Includes a factory installed mixing tube and discharge

air sensor for cooling package units. For blower package

units, the air sensor is factory wired but field installed in

duct work. The set point adjuster is field installed remotely

and must be field set. Refer to Literature 5-578 latest

revision.

figure 19.3 - electronic modulating discharge air

thermostat

(2) low gas Pressure switch – (oPt)

The low gas pressure switch is factory installed in the duct

furnace above the gas train. The switch monitors the gas

pressure upstream of all the gas controls and shuts off the

electric supply to the ignition controller and combination gas

valve if low gas pressure is experienced. This will shut off all

gas flow to the burner. The switch has an automatic reset so

that if the gas pressure is interrupted and then is returned, the

switch will automatically allow the unit to operate when gas

conditions are returned to the allowable range of the pressure

switch. The pressure switch range is 2" to 14" W.C. and should

be set to insure that the minimum inlet gas pressure is available

(6" W.C. for natural gas, 11" W.C. for propane gas).

figure 19.4 - low or High gas Pressure switch

(3) High gas Pressure switch – (oPt)

The high gas pressure switch is factory installed in the duct

furnace above the gas train. The switch monitors the gas

pressure downstream of all the gas controls and shuts off

the electric supply to the ignition controller and combination

gas valve if high gas pressure is experienced right before the

manifold. This will shut off all gas flow to the burner. The switch

has a

manual reset so that if the gas pressure is too high, a

service person must check the unit to make sure that none of

the gas controls have been damaged by the high gas pressure

and then reset the switch to allow the unit to operate when gas

conditions are returned to the allowable range of the pressure

switch. The pressure switch range is 2" to 16" W.C. and should

be set to insure that the maximum manifold gas pressure is not

exceeded (3.5" W.C. for natural gas, 10" W.C. for propane gas).

(5) timed freeze Protection – (oPt)

The timed freeze protection system is factory installed in the

duct furnace electrical junction box with the sensor (30°-75°F

adjustable) factory installed in the discharge air stream. On

initial start-up, the timed delay in the system allows the unit to

go through the normal ignition sequence. The timed delay is an

automatic reset switch and adjustable for 1-10 minutes. In the

event that the unit fails to fire after this period, the discharge air

sensor will sense the cold air and will shut down the entire unit.

Duct Furnace

Electrical

Control

Box

Air flow

3

2

1

Mixing Tube

Discharge air

Sensor Terminals

Gas Control Knob

Hydrostatic Sensing Bulb

HI 8 7 6

5

4

3

2

1

LO

IN

OFF

NO

Control Dial

Hydrostatic Sensing Bulb

Gas Control Knob

Control Dial

Box

Control

Electrical

Duct Furnace

Sensor

Duct

Furnace

Electrical

Control

Box

Sensor

Pressure adjustment screw

(High Pressure Switch only)

Reset Switch

C

NO

NC

Top: cover removed

Pressure adjustment screw

Reset Switch

(High Pressure Switch only)

Top cover removed

figure 19.5 - timed freeze Protection module