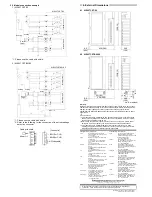

3. Name of Each Part

A1S62TCRT-S2

NC

NC

NC

NC

NC

NC

NC

b2

B2

A2

NC

NC

b1

B1

A1

+

L2C

L2H

L1C

L1H

-

CH1

H OUT

C OUT

ALM

RUN

H OUT

C OUT

ALM

CH2

A1S62TCRTBW-S2

NC

NC

NC

NC

NC

NC

NC

b2

B2

A2

NC

NC

b1

B1

A1

;

L2C

L2H

L1C

L1H

-

CH1

H OUT

C OUT

ALM

BR.W

RUN

CH2

H OUT

C OUT

ALM

BR.W

1)

1)

2)

2

4

6

8

10

12

14

16

18

20

1

3

5

7

9

11

13

15

17

19

2

4

6

8

10

12

14

16

18

20

1

3

5

7

9

11

13

15

17

19

A1S62TCRT-S2

A1S62TCRTBW-S2

A1S62TCRT-S2 LED

A1S62TCRTBW-S2 LED

A

1S62TCRT-S2

CH1

H OUT

C OUT

ALM

RUN

H OUT

C OUT

ALM

CH2

A

1S62TCRTBW-S2

CH1

H OUT

C OUT

ALM

BR.W

RUN

CH2

H OUT

C OUT

ALM

BR.W

Number

Name

Description

RUN

A1S62TC operation status display

ON: Normal operation in progress

Flashing (2 sec. ON/2 sec. OFF): Write data error

Flashing (1 sec. ON/1 sec. OFF): Hardware error

OFF: 5V power shutoff, Watchdog timer error

OUT

Transistor output status display

ON: Transistor output ON

OFF: Transistor output OFF

ALM

Alert alarm status display

ON: Alert alarm is ON.

Flashing: The measured temperature range is

exceeded.

The platinum temperature-measuring

resistor is not connected.

The platinum temperature-measuring

resistor cable is disconnected.

OFF: Alert alarm is OFF

1)

LED

BR.W

Heater wire breakage detection status display

ON: Heater wire breakage is detected.

OFF: Heater wire breakage is not detected.

2)

Wire

breakage

detection

connector

Connector for current sensor

Wire breakage detection

connector installation screw

Cable fixing screw

BW1(For CH1)

BW2(For CH2)

NC(Unusable)

4. Loading and Installation

Precautions when handling the A1S62TC and installation environment

are explained.

For details of implementing and setting up this unit, please refer to the

User’s Manual for the PC CPU used.

4.1 Handling Instructions

1) The module case is made of plastic. Be sure not to drop it or

subject it to strong vibration.

2) Do not remove the module printed circuit boards from the case.

It may cause trouble.

3) When connecting the wiring, do not allow wire cuttings or other

foreign matter to enter from the top of the module. Remove any

foreign matter from the module.

4) Tighten the module installation screws within the following

tightening torque range.

Screw position

Tightening torque range

Module installation screw (M4 screw)

78 to 118N

•

cm

Terminal block terminal screw (M3.5 screw)

59 to 88N

•

Terminal block installation screw (M4 screw)

78 to 118N

•

cm

Wire breakage detection connector installation

screw (M2.6 screws)*

15 to 30N

•

cm

Cable fixing screw (M2 screws)*

11 to 14N

•

cm

*:Use only for A1S62TCRTBW-S2 .

4.2 Installations Enviroment

Never install the AnS series PC system in the following environments:

1) Locations where the ambient temperature is outside the range of

0 to 55

.

2) Locations where the ambient humidity is outside the range of 10

to 90%RH.

3) Locations where dew condensation takes place due to sudden

temperature changes.

4) Locations where there are corrosive and/or combustible gasses.

5) Locations where there is a high level of conductive power (such

as dust and iron filings, oil mist, salt, and organic solvents).

6) Locations exposed to the direct rays of the sun.

7) Locations where strong power and magnetic fields are generated.

8) Locations where vibration and shock are directly transmitted to

the main module.

5. Wiring

The precaution when wiring and the module connection example are

shown below.

5.1 Precaution when wiring

In order to have the best result from the A1S62TC functions and to

make the system highly reliable, an external cabling with low noise

effects are necessary.

The external wiring precautions are shown below:

1) Use separate cables for the alternating current and A1S62TC

external input signals to avoid A/C surges and induction effects.

2) Do not bunch the cables with the main circuit, high-voltage cable

or load cables from other than PC, or install them close to each

other.

Install the cables far apart from high-frequency circuits, such as the

high-voltage cable and inverter load main circuit, as much as

possible.

This increases the noises, surges, and induction.

3) Perform a one-point grounding for the shielded line and shields of

the seal and cable at the PC. However, there may be cases

when grounding should be performed externally depending on

the noise condition.