A.3

Error Code List

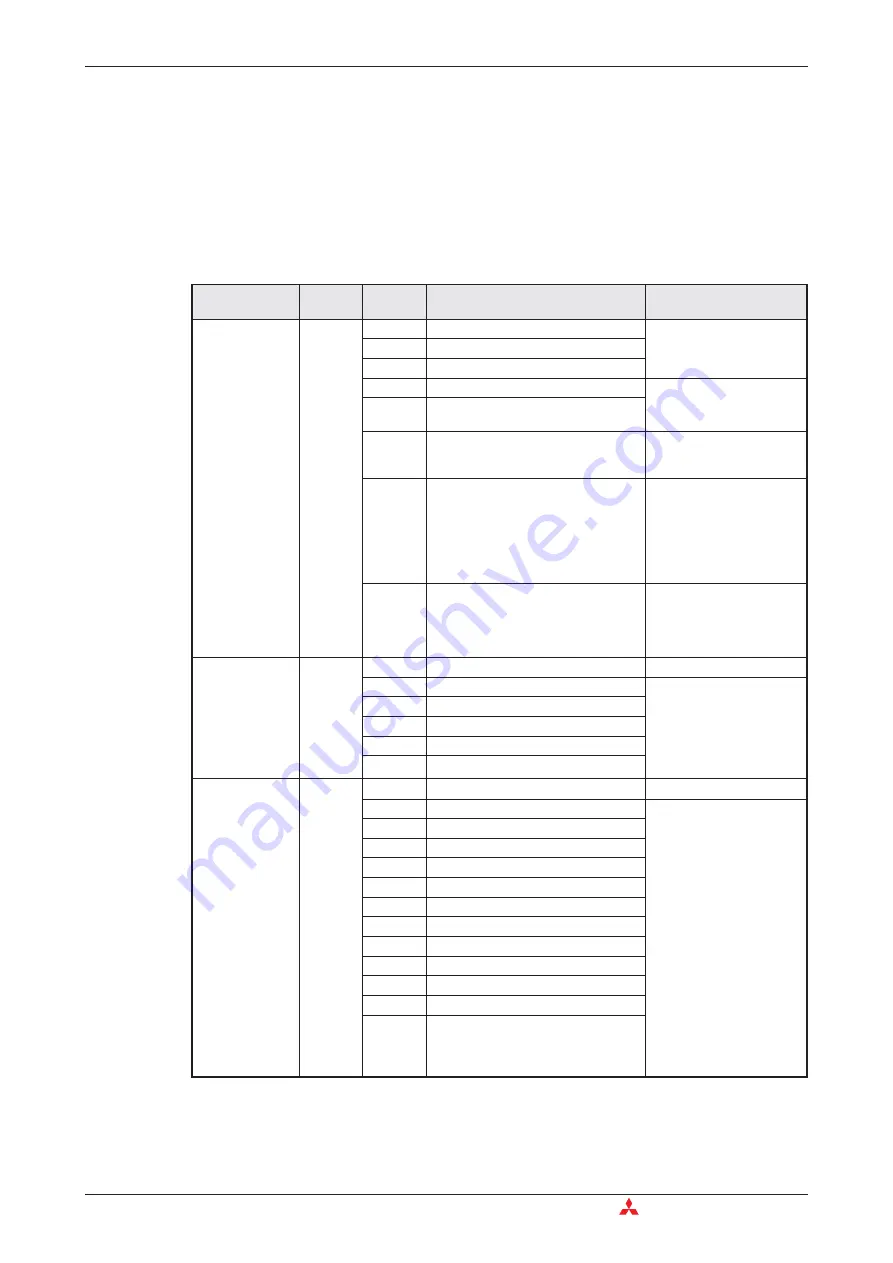

When an error has been detected in the PLC, the error code is stored in special registers D8060

to D8067 and D8438. The following actions should be followed for diagnostic errors.

Represented here are some of the most common error codes.

A.3.1

Error codes 6101 to 6409

Error Code List

Appendix

A - 10

MITSUBISHI ELECTRIC

Error

Special

Register

Error

Code

Description

Corrective Action

PLC

hardware error

D8061

0000

No error

—

6101

RAM error

6102

Operation circuit error

6103

I/O bus error (M8069 = ON)

Check for the correct con-

nection of extension cables.

6104

Powered extension unit 24 V failure

(M8069 = ON)

6105

Watchdog timer error

Check user program. The

scan time exceeds the value

stored in D8000.

6106

I/O table creation error (CPU error)

When turning the power ON to the

baseunit, a 24V power failure occurs in

a powered extension unit. (The error

occurs if the 24V power is not supplied

for 10 seconds or more after main

power turn ON.)

Check the power supply for

the powered extension

units.

6107

System configuration error

Check the number of the

connected special function

units/blocks. A few special

function units/blocks are lim-

ited the number to connect.

Communication

error between

PLC and program-

ming device

(FX

2N

and FX

2NC

only)

D8062

0000

No error

—

6201

Parity, overrun or framing error

Check the cable connection

between the programming

device and the PLC. This

error may occur when a

cable is disconnected and

reconnected during PLC

monitoring.

6202

Communication character error

6203

Communication data sum check error

6204

Data format error

6205

Command error

Serial

communication

error

D8063

0000

No error

—

6301

Parity, overrun or framing error

쎲

Inverter communication,

computer link and pro-

gramming: Ensure the

communication parame-

ters are correctly set ac-

cording to their applica-

tions.

쎲

N:N network, parallel

link, etc.: Check pro-

g r a m s a c c o r d i n g t o

applications.

쎲

Remote maintenance:

Ensure modem power is

ON and check the set-

t i n g s

o f

t h e

AT

commands.

쎲

Wiring: Check the com-

munication cables for

correct wiring.

6302

Communication character error

6303

Communication data sum check error

6304

Communication data format error

6305

Command error

6306

Communication time-out detected

6307

Modem initialization error

6308

N:N network parameter error

6312

Parallel link character error

6313

Parallel link sum error

6314

Parallel link format error

6320

Inverter communication error

Summary of Contents for FX2N-32CAN

Page 1: ...MITSUBISHI ELECTRIC FACTORY AUTOMATION Programmable Logic Controllers GX IEC Developer ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 10: ...IV MITSUBISHI ELECTRIC ...

Page 18: ...Modular PLC Training Hardware Course Overview and Requirements 1 2 MITSUBISHI ELECTRIC ...

Page 176: ...Device Edit 8 4 MITSUBISHI ELECTRIC ...

Page 190: ...Assigning DUT Variables to Function Blocks Data Unit Types DUT 10 10 MITSUBISHI ELECTRIC ...

Page 198: ...Array Example Single Dimension Array Arrays 11 8 MITSUBISHI ELECTRIC ...

Page 219: ...Sequential Function Chart SFC SFC Elements Training Manual GX IEC Developer 14 3 ...

Page 230: ...Structured Text Program Example IEC Structured Text 16 4 MITSUBISHI ELECTRIC ...

Page 278: ...PLC Components Glossary Appendix A 18 MITSUBISHI ELECTRIC ...

Page 283: ......