GB

4

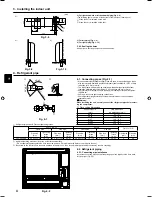

3. Installing the indoor unit

2) For right downward or left downward piping (Fig. 3-8)

(The following figure is a view of the bottom of the indoor unit from above.)

A

When the unit is installed on the wall.

B

When the unit is installed on the floor.

150

168

200

73

105

147

60

700

75

62

31

61

Fig. 3-8

60

19

60

19

60

60

Fig. 3-10

Fig. 3-9

2)

(mm)

4)

3)

3) For left piping (Fig. 3-9)

4) For right piping (Fig. 3-10)

3.4.3. Sealing the holes

Use putty or a caulking compound to seal the holes.

4. Refrigerant pipe

4.1. Connecting pipes (Fig. 4-1)

• When commercially available copper pipes are used, wrap liquid and gas pipes

with commercially available insulation materials (heat-resistant to 100°C or more,

thickness of 12 mm or more).

• The indoor parts of the drain pipe should be wrapped with polyethylene foam

insulation materials (specific gravity of 0.03, thickness of 9 mm or more).

• Apply thin layer of refrigerant oil to pipe and joint seating surface before tighten-

ing flare nut.

• Use two wrenches to tighten piping connections.

• Use refrigerant piping insulation provided to insulate indoor unit connections.

Insulate carefully.

Warning:

When installing the unit, securely connect the refrigerant pipes before start-

ing the compressor.

Copper pipe O.D.

(mm)

Flare dimensions

øA dimensions (mm)

ø6.35

8.7 - 9.1

ø9.52

12.8 - 13.2

ø12.7

16.2 - 16.6

ø15.88

19.3 - 19.7

ø19.05

23.6 - 24.0

A

Flare cutting dimensions

B

C

D

90

°

±0.5°

øA

R0.4 - R0.8

A

45°±2°

Fig. 4-1

B

Refrigerant pipe sizes & Flare nut tightening torque

R407C or R22

R410A

Flare nut O.D.

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

Pipe size

(mm)

Tightening

torque

(N·m)

Pipe size

(mm)

Tightening

torque

(N·m)

Pipe size

(mm)

Tightening

torque

(N·m)

Pipe size

(mm)

Tightening

torque

(N·m)

Liquid pipe

(mm)

Gas pipe

(mm)

P20/25/32/40

O.D. ø6.35 (1/4”)

14 - 18

O.D. ø12.7 (1/2”)

49 - 61

O.D. ø6.35 (1/4”)

14 - 18

O.D. ø12.7 (1/2”)

49 - 61

17

26

C

Apply refrigerating machine oil over the entire flare seat surface.

* Do not apply refrigerating machine oil to the screw portions. (This will make the flare nuts more apt to loosen.)

D

Be certain to use the flare nuts those are attached to the main unit. (Use of commercially-available products may result in cracking.)

Fig. 4-2

4.2. Refrigerant piping

4.2.1. Connecting pipe installation

Install the connecting pipes so that the piping can move slightly to the front, back,

left, and right. (Fig. 4-2)