3

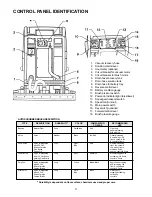

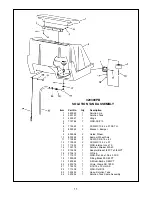

1. Vacuum recovery hose

2. Solution control lever

3. Hour meter (optional)

4. Circuit breaker for vacuum motor

5. Circuit breaker for brush motor

6. Drain hose recovery tank

7. Drain hose solution tank

8. Drain hose for battery tray

9. Reverse control lever

10. Battery condition gauge

11. Brush pressure switch

12. Power-on Indicator light (raise/lower)

13. Squeegee/transport switch

14. Speed control knob

15. Main power switch

16. Key switch (optional)

17. Forward control lever

18. Brush pressure gauge

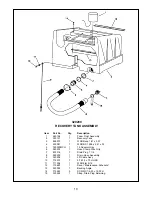

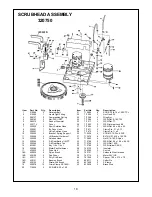

AUTO SCRUBBER BRUSH DESCRIPTION

TYPE

DESCRIPTION

DURABILITY*

COLOR

COMPARISON

RECOMMENDED

TO PADS

USE

Bassine

Natural Fiber

Short

DarkBrown

Red

Light duty

general cleaning,

acid etching

Nylon

Nylon

Medium

Black

Tan/Red

General cleaning

& scrubbing vinyl

floors, ceramic tile

& concrete floors

Dyna-Scrub

Nylon impregnated

Long

Light

Red

General scrubbing,

with 500 Grit

Blue

vinyl tile, ceramic

Silicone Carbide

tile, epoxy floors,

Fine Bristle,

urethane finish,

Dense Fill

uneven concrete floors

Power-Scrub

Nylon impregnated

Long

Rust

Red/Blue

Moderate aggressive

with 120 Grit Silicon

scrubbing, tile floors

Carbide Fine Bristle,

concrete floors

Dense Fill

Poly-Grit

Nylon impregnated

Long

Green

Brown/Black

Aggressive stripping

with 80 Grit

and scrubbing, tile

Silicon Carbide

floors, unfinished

Coarse Bristle

concrete floors

Strata-Grit

Nylon impregnated

Long

Dark

Black

Heavy duty

with 46 Grit

Blue

stripping/scrubbing

Silicon Carbide

unfinshed

Coarse Bristle

concrete

*

Durability is dependent on floor surface, chemicals used and proper care.

CONTROL PANEL IDENTIFICATION

Summary of Contents for Powerboss PB32036CE

Page 2: ......

Page 11: ...8 ...

Page 15: ...12 ...

Page 17: ...14 ...

Page 19: ...16 ...

Page 24: ...21 WIRING DIAGRAM STANDARD MODEL ...

Page 25: ...22 WIRING DIAGRAM CE MODEL ...