10. Testing the Throttle Potentiometer

9.

Riders Only

: Measure resistance across the black and white wires on the potentiometer, the resistance should be

zero ohms with pedal on the riders in the neutral position. When the pedal or knob is moved to the full throttle

position, in should be a smooth resistance change without dropping out. It should measure approximately 5K (5

thousand ohms) in the full position.

ES2832 and CP2832 Only:

Disconnect the potentiometer at the connector next to it. Measure resistance across

the black/orange and black/white wires should be 5 K ohms.

12.

Riders Only:

Measuring across the black and the red wire the resistance should be approximately 5K (5

thousand), when in the neutral position. When the pedal is at full throttle or the knob is full speed position, the

resistance should drop to zero without being intermittent.

ES2832 and CP2832 Only:

Disconnect the potentiometer at the connector next to it. Measure the resistance

across the black/orange and black/pink wires. The resistance should drop to zero without being intermittent when

turning the knob of the potentiometer. Note: The drive switch will need to be activated when doing this test.

13. If adjustment is needed, loosen the nut and screw on the throttle arm. Adjust the potentiometer shaft with a flat tip

screw driver, until it is set according to the information above (on the riders only).

14. Reconnect the plug at the throttle potentiometer.

Note: when moving the throttle to the full position, the resistance should be smooth, without dropping out for

both tests. If the resistance does not go to 5K during the test, the arm and the potentiometer may need to

be adjusted to achieve it.

9.

Riders Only

: Measure resistance across the black and white wires on the potentiometer, the resistance should be

zero ohms with pedal on the riders in the neutral position. When the pedal or knob is moved to the full throttle

position, in should be a smooth resistance change without dropping out. It should measure approximately 5K (5

thousand ohms) in the full position.

ES2832 and CP2832 Only:

Disconnect the potentiometer at the connector next to it. Measure resistance across

the black/orange and black/white wires should be 5 K ohms.

12.

Riders Only:

Measuring across the black and the red wire the resistance should be approximately 5K (5

thousand), when in the neutral position. When the pedal is at full throttle or the knob is full speed position, the

resistance should drop to zero without being intermittent.

ES2832 and CP2832 Only:

Disconnect the potentiometer at the connector next to it. Measure the resistance

across the black/orange and black/pink wires. The resistance should drop to zero without being intermittent when

turning the knob of the potentiometer. Note: The drive switch will need to be activated when doing this test.

13. If adjustment is needed, loosen the nut and screw on the throttle arm. Adjust the potentiometer shaft with a flat tip

screw driver, until it is set according to the information above (on the riders only).

14. Reconnect the plug at the throttle potentiometer.

Note: when moving the throttle to the full position, the resistance should be smooth, without dropping out for

both tests. If the resistance does not go to 5K during the test, the arm and the potentiometer may need to

be adjusted to achieve it.

Page 44

Potentiometer Assembly – Riders only

Adjust Here

Summary of Contents for ES2832

Page 6: ...2 1 Minuteman System Maintenance K Page 6 ...

Page 7: ...2 2 Minuteman System Maintenance I Page 7 ...

Page 8: ...2 3 Minuteman System Maintenance II Page 8 ...

Page 9: ...2 4 Minuteman System Maintenance S Page 9 ...

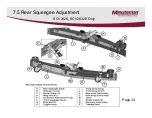

Page 34: ...7 5 Rear Squeegee Adjustment SCV2426 SCV2832E Only Page 34 ...

Page 35: ...7 6 Rear Squeegee Adjustment SCV2426 SCV2832E Only Page 35 ...

Page 38: ...8 1 Actuator Adjustment 742712 2 only Page 38 ...

Page 49: ...13 Notes ...