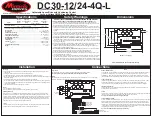

COIL

MOTOR

CL

REGEN

CL

FWD

SPEED

REV

SPEED

FB

OFFSET

FB

GAIN

BAND

DEAD

ERROR

GAIN

POWER

CUR LMT

A1

MOTOR

3 (Common)

2 (Wiper)

1 (+5V)

9

8

7

10

6

5

4

POSITION COMMAND POT

REVERSE INHIBIT

(Close to Run)

ENABLE

FORWARD INHIBIT

(Close to Run)

(Close to Run / Open to Coast to Stop)

FEEDBACK POT

FUSE

+

_

+

_

DC POWER

SOURCE

MOTOR

Posi�on Poten�ometer

Use a 10K ohm, 1/4 W poten�ometer for posi�on control. Connect the counter-clockwise end of the

poten�ometer to terminal 3, the wiper to terminal 2, and the clockwise end to terminal 1. If the

poten�ometer works inveresly of desired func�onality, (i.e. to move motor forward, you must turn

the poten�ometer counterclockwise), power off the drive and swap the terminal 1 and 3 connec�ons.

Posi�on Analog Signal

Instead of using a poten�ometer, the drive may be wired to follow an analog input signal of 0 - 5 VDC.

Connect the signal common / nega�ve (-) to terminal 3 and the signal reference /posi�ve (+) to

terminal 2. The drive is not isolated and the common terminal 3 is connected to ba�ery nega�ve.

Feedback Poten�ometer

Connect the common / nega�ve end of the poten�ometer to terminal 3, the referece to terminal 5,

and the posi�ve end to terminal 1.

Enable

Connect an enable switch to terminals 4 and 6. Close the connec�on to run and open the connec�on to

coast the motor to a stop. If no switch is desired, jumper terminals 4 and 6.

Do not use the Enable func�on for emergency stopping.

Forward & Reverse Inhibit

Connect a forward inhibit switch to terminals 7 and 8 and a reverse inhibit switch to terminals 9 and 10.

Opening a connec�on regenera�vely brakes the motor to a stop. The forward inhibit switch has no

effect if the motor is running in reverse, and vice versa. The inhibits can be used with normally closed

switches to act as end-of-travel limits. If the use of only one inhibit switch is desired, jumper terminals

7 and 9 and then connect the switch to either the forward or reverse inhibit input. If no inhibit switches

are desired, jumper terminals 7 and 8 and jumper terminals 9 and 10.

Do not use the Inhibit func�ons for emergency stopping.

LOGIC

Input Power

Connect the DC input power leads to terminals POS (posi�ve) and NEG (nega�ve).

Connec�ng the DC input power backwards will cause damage to the drive.

Motor

Connect the DC armature leads to terminals A1 and A2. If the motor does not spin in the desired

direc�on, power down the drive and reverse these connec�ons.

POWER

Connections

Moun�ng

• Drive components are sensi�ve to electrosta�c discharge. Avoid direct contact with the circuit

•

components.

• Protect the drive from dirt, moisture, and accidental contact.

• Provide sufficient room for access to the terminal block and calibra�on trim pots.

• Mount the drive away from heat sources. Operate the drive within the specified ambient opera�ng

•

temperature range.

• Prevent loose connec�ons by avoiding excessive vibra�on of the drive.

• Mount the drive with its board in either a horizontal or ver�cal plane. Six 0.15” (4 mm) wide slots

•

in the chassis accept #8 pan head screws. Fasten either the large base or the narrow flange of the

chassis to the subplate.

• The chassis should be earth grounded when possible.

Wiring

Use 18 - 24 AWG wire for logic wiring.

Use

10 - 12 AWG wire for DC source (POS, NEG) and motor (A1, A2) wiring.

Shielding Guidelines

As a general rule, it is recommended to shield all conductors. If it is not prac�cal to shield power

conductors, it is recommended to shield all logic-level leads. If shielding of logic-level leads is not

prac�cal, the user should twist all logic leads with themselves to minimize induced noise. It may be

necessary to earth ground the shielded cable. If noise is produced by devices other than the drive,

ground the shield at the drive end. If noise is generated by the drive, ground the shield at the end

away from the drive. Do not ground both ends of the shield.

Fusing

The drive requires an external line fuse for protec�on. Use fast ac�ng fuses rated for at least 150%

of the maximum armature voltage and current. Fuse the posi�ve terminal.

Installation

3.00 [76]

2.64 [67]

1.75 [44]

3.80 [97]

4.30 [109]

0.19 [5]

Height = 1.41 [35.8]

MOTOR

CL

REGEN

CL

FWD

SPEED

REV

SPEED

FB

OFFSET

FB

GAIN

BAND

DEAD

ERROR

GAIN

MOTOR

A1

ALL DIMENSIONS IN INCHES [MILLIMETE

R

S]

Dimensions

•

DO NOT INSTALL, REMOVE, OR REWIRE THIS EQUIPMENT WITH POWER APPLIED.

Have a

•

qualified electrical technician install, adjust and service this equipment. Follow the Na�onal

•

Electrical Code and all other applicable electrical and safety codes, including the provisions of the

•

Occupa�onal Safety and Health Act (OSHA), when installing equipment.

• Avoid direct contact with the printed circuit board or with circuit elements to prevent the risk of

•

serious injury or fatality. Use a non-metallic screwdriver for adjus�ng the calibra�on trim pots. Use

•

approved personal protec�on equipment and insulated tools if working on this drive with power

•

applied.

• The drive is not diode-protected from reverse ba�ery voltage. You must ensure that the posi�ve

•

terminal is wired to POS and the nega�ve terminal is wired to NEG.

• Reduce the chance of an electrical fire, shock, or explosion by using proper grounding techniques,

•

over-current protec�on, thermal protec�on, and enclosure. Follow sound maintenance procedures.

•

Removing DC power is the only acceptable method for emergency stopping.

Do not use

•

regenera�ve braking, decelera�ng to minimum speed, or coas�ng to a stop for emergency stopping.

•

They may not stop a drive that is malfunc�oning. Removing DC power is the only acceptable method

•

for emergency stopping.

• Applying and removing DC source voltage is recommended for infrequent star�ng and stopping of a

•

drive only. Regenera�ve braking, decelera�ng to minimum speed, or coas�ng to a stop is

•

recommended for frequent starts and stops. Frequent star�ng and stopping can produce high

•

torque. This may cause damage to motors.

•

Do not disconnect any of the motor leads from the drive

unless power is removed or the drive is

•

disabled. Opening any one lead while the drive is running may destroy the drive.

• Under no circumstances should power and logic level wires be bundled together.

• Be sure poten�ometer tabs do not make contact with the poten�ometer’s body. Grounding the

•

input may cause damage to the drive.

• This product does not have internal solid state motor overload protec�on. It does not contain speed-

•

sensi�ve overload protec�on, thermal memory reten�on, or provisions to receive and act upon

•

signals from remote devices for over temperature protec�on. If motor protec�on is needed in the

•

end-use product, it needs to be provided by addi�onal equipment in accordance with NEC standards.

READ ALL SAFETY WARNINGS BEFORE INSTALLING THIS EQUIPMENT

Safety Warnings

............................................................................................................8 - 32 VDC

...................................................................................................1.01 at base speed

..................................................................................0.5 - 16 seconds

..................................................................................0.5 - 16 seconds

........................................................................................0 - 5 VDC

.....................................................................................

>100K ohms

..................................................................................................1% base speed

......................................................................................................................100:1

............................................................................................0.5G maximum

...............................................................................................0.1G maximum

.....................................................................................0°C - 55°C

..............................................................................................................................0.6 lbs

Source Voltage

Form Factor

Accelera�on Time Range

Decelera�on Time Range

Analog Input Voltage Range

Input Impedance (S1 to S2)

Load Regula�on

Speed Range

Vibra�on

(0 - 50 Hz)

(>50 Hz)

Ambient Temperature Range

Weight

* Peak current ra�ng for 1 minute. Con�nuous current ra�ng is 15 amps.

1/50 - 1/6

1/25 - 1/3

Motor

Horsepower

Range

30*

Peak

Armature

Current (Amps)

Up to 95%

of Source Voltage

Armature

Voltage Range

(VDC)

12

24

Source

Voltage

(VDC)

DC30-12/24-4Q-L

Model

Specifications

4Q PWM Microprocessor-based Chassis

Adjustable Speed Drive with Positioning Control

for Low Voltage PMDC Brushed Motors

DC30-12/24-4Q-L

An American Control Electronics Brand