14

5. Periodically care (Once a year)

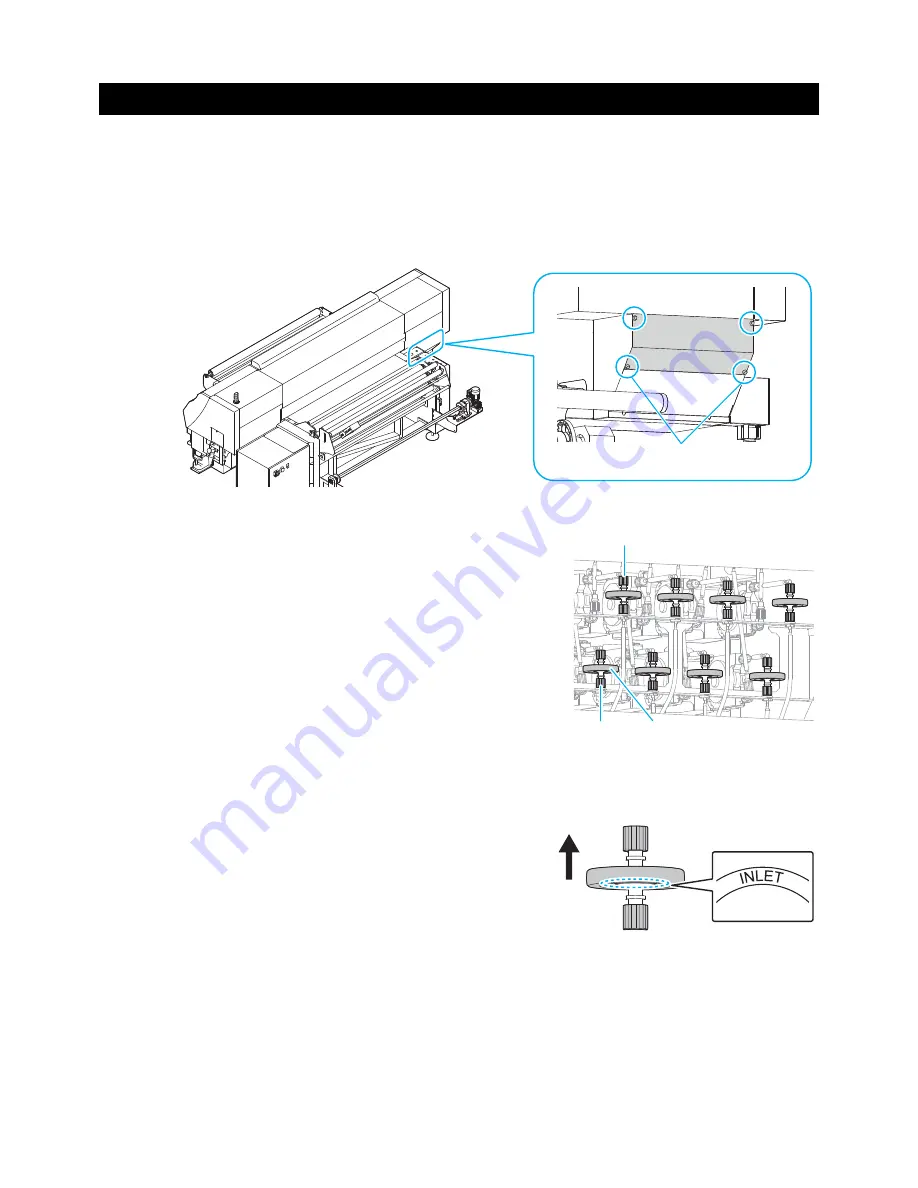

(1) Replacing the ink filter at main body side

Replace it once a year.

1

After turning off the main power switch, open the rear maintenance cover (right) of

the rear surface right side of this machine.

• Remove the screws (for 4 positions) of the rear surface maintenance cover (right).

2

Loosen the joints of upper/ lower of the ink filter.

3

Replacing the used ink filter.

4

Attach new ink filter (SPA-0196), and tighten

the joint.

• When attaching the ink filter, be careful of the ink

feeding direction.

• Face the side of the filter with “INLET” written on it

downwards and attach the filter.

5

Return the rear surface maintenance cover (right) to the original position, and turn on

the main power switch.

Screw

Joint

Joint

Ink filter

In

k fe

ed

in

g

di

recti

o

n

Summary of Contents for Tx500-1800B

Page 22: ...22 MEMO...

Page 23: ...23 MEMO...