CHAPTER 5

TROUBLE SHOOTING AND POSSIBLE REMEDY

5-7

No

No

No

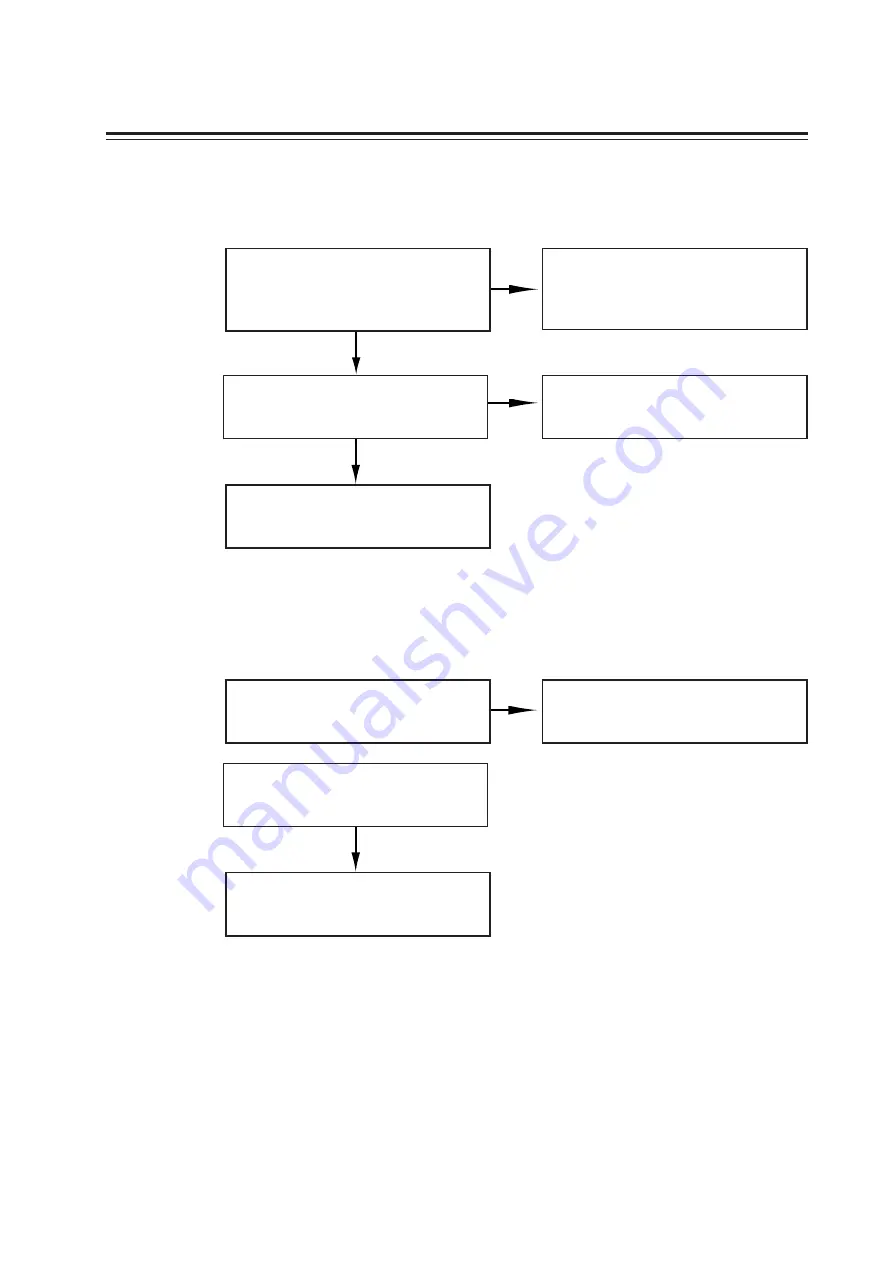

Paper is caught at the part cut portion, resulting in paper jam-

ming.

Is pressure command for the part

that remains uncut under the dotted

line cut mode transmitted from

CAD?

Check to be sure that dotted line cut

mode is ON and lower the dotted

line cutting pressure. See page 2-

15.

Is residual part length command for

the dotted line cut mode transmitted

from CAD?

Check to be sure that dotted line cut

mode is ON and increase the re-

sidual part length. See page 2-15.

C h a n g e p a r a m e t e r s e s t a b l i s h e d

on CAD properly.

Paper is caught at the auto cut portion, resulting in paper jam-

ming.

Does paper jamming arise in any

case other than the time immedi-

ately after auto-cut?

Increase the slant cutting amount.

See page 3-27.

Does paper jamming arise particu-

larly when remaining amount of roll

paper is small?

Increase the slant cutting amount.

See page 3-27.

INDICATIONS OF FAILURE

Yes

Yes

Yes

Summary of Contents for cg-100AP

Page 16: ...xiv ...

Page 70: ...1 54 ...

Page 108: ...2 38 ...

Page 145: ...CHAPTER 4 SELF DIAGNOSIS FUNCTION 4 9 DEMONSTRATION PATTERN 1 2 Demonstration Pattern 1 ...

Page 146: ...4 10 Demonstration Pattern 2 ...

Page 173: ...CHAPTER 6 APPENDIX 6 13 Table of 82 special character codes supported ...

Page 179: ...D200310MAC 2 00 09061999 ...

Page 180: ... MIMAKI ENGINEERING CO LTD 1999 6 Printed in japan ...