SCROLL 15SP1CB / 13SP2CB – 35SP1CB / 29SP2CB – 52SP1CB / 42SP2CB

520606-00

7

EN

Table 1.

Amount of supplying grease

[0.83MPa use for 15SP1CB; 35SP1CB; 0.8MPa use for 52SP1CB]

Item

Amount of supplying grease

0h

2,500h

2,501h

5,000h

5,001h

7,500h

7,501h

10,000h

15SP1CB

Main shaft

bearing

5 strokes

(2.8±0.3 g)

9 strokes

(5.0±0.5 g)

13 strokes

(7.3±0.6 g)

15 strokes

(8.4±0.6 g)

Support bearings

(3 places)

1 stroke

(0.6±0.1 g)

2 strokes

(1.1±0.1 g)

3 strokes

(1.7±0.2 g)

4 strokes

(2.2±0.2 g)

35SP1CB

Main shaft

bearing

5 strokes

(2.8±0.3 g)

9 strokes

(5.0±0.5 g)

13 strokes

(7.3±0.6 g)

15 strokes

(8.4±0.6 g)

Support bearings

(3 places)

1 stroke

(0.6±0.1 g)

2 strokes

(1.1±0.1 g)

3 strokes

(1.7±0.2 g)

4 strokes

(2.2±0.2 g)

52SP1CB

Main shaft

bearing

5 strokes

(2.8±0.3 g)

11 strokes

(6.2±0.4 g)

16 strokes

(9.0±0.5 g)

22 strokes

(12.3±0.6 g)

Support bearings

(3 places)

1 stroke

(0.6±0.1 g)

2 strokes

(1.1±0.1 g)

3 strokes

(1.7±0.2 g)

5 strokes

(2.8±0.2 g)

Table 2.

Amount of supplying grease

[1.0MPa use for all models]

Item

Amount of supplying grease

0h

1,250h

1,251h

2,500h

2,501h

3,750h

3,751h

5,000h

13SP2CB

Main shaft

bearing

5 strokes

(2.8±0.3 g)

9 strokes

(5.0±0.5 g)

13 strokes

(7.3±0.6 g)

15 strokes

(8.4±0.6 g)

Support bearings

(3 places)

1 stroke

(0.6±0.1 g)

2 strokes

(1.1±0.1 g)

3 strokes

(1.7±0.2 g)

4 strokes

(2.2±0.2 g)

29SP2CB

Main shaft

bearing

5 strokes

(2.8±0.3 g)

9 strokes

(5.0±0.5 g)

13 strokes

(7.3±0.6 g)

15 strokes

(8.4±0.6 g)

Support bearings

(3 places)

1 stroke

(0.6±0.1 g)

2 strokes

(1.1±0.1 g)

3 strokes

(1.7±0.2 g)

4 strokes

(2.2±0.2 g)

42SP2CB

Main shaft

bearing

5 strokes

(2.8±0.3 g)

11 strokes

(6.2±0.4 g)

16 strokes

(9.0±0.5 g)

22 strokes

(12.3±0.6 g)

Support bearings

(3 places)

1 stroke

(0.6±0.1 g)

2 strokes

(1.1±0.1 g)

3 strokes

(1.7±0.2 g)

5 strokes

(2.8±0.2 g)

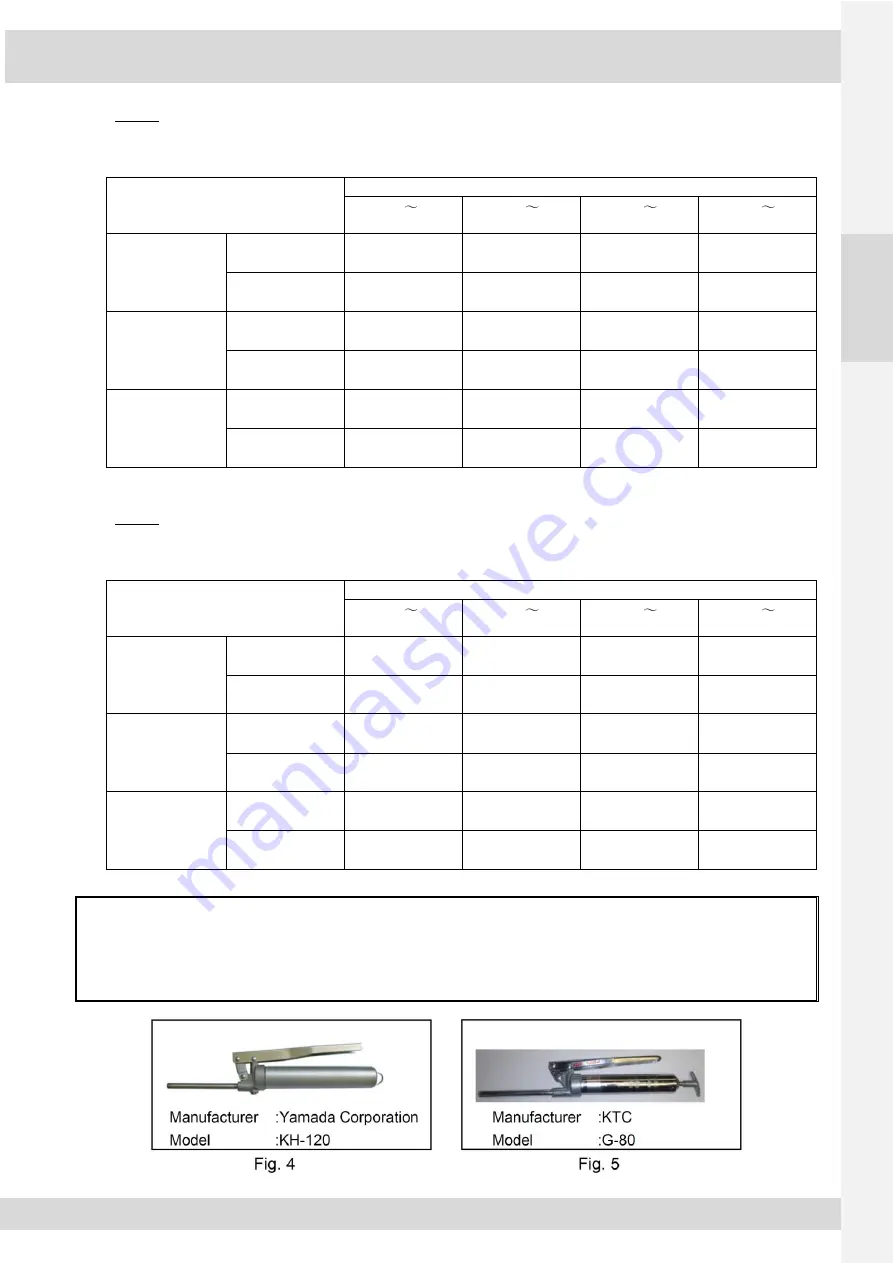

Note:

1) Use grease gun as shown in Fig 4 or 5 when supplying grease into each bearings.

2) Do not supply grease into each bearings beyond specified number show in above table, otherwise the bearings are damaged.

3) The amount of supplying grease should be determined based on operating time mentioned below.

1st time: Operating time from start operation

2nd time: Operating time from the last time maintenance

Summary of Contents for 13SP2CB

Page 16: ...www mils fr...