OM-230 161 Page 8

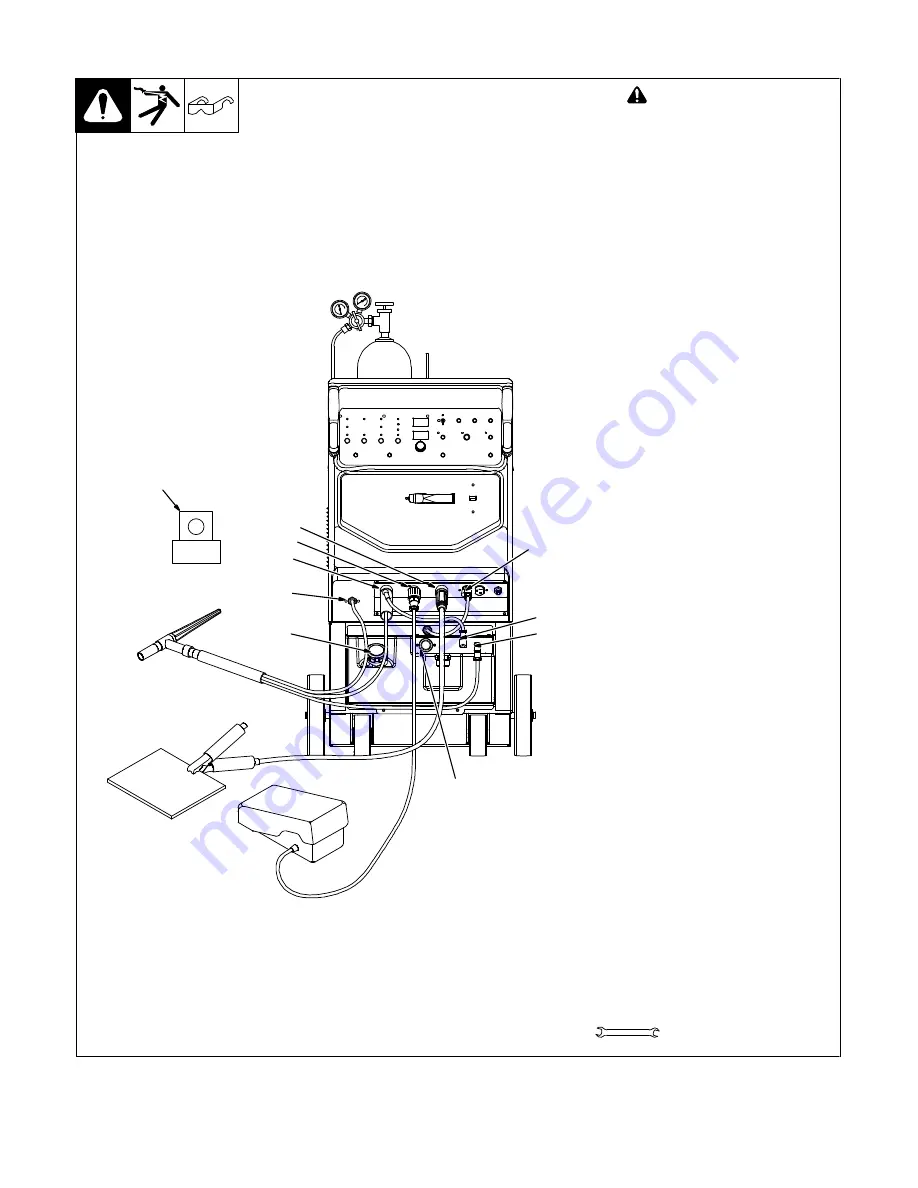

6-2. Optional Cooler Connections

805 102-B

Tools Needed:

11/16 in. (21 mm for CE units)

!

Disconnect cooler plug from

welding power source re-

ceptacle before filling.

1

Cap

Remove cap and fill tank with three

gallons of coolant (see Section

4-3).

2

Gas Out Connection

Connect TIG torch gas hose to gas

out fitting.

3

Electrode Weld Output

Terminal

4

TIG Block (Customer Sup-

plied)

Connect TIG torch to electrode

weld output terminal. Note: Some

models may require a TIG block

instead of the international style

water connector.

5

Remote 14 Receptacle

Connect remote control to recep-

tacle if desired.

6

Work Weld Output Terminal

Connect work lead to work weld

output terminal.

7

Water-In (From Torch)

Connection

Connect torch water-out (red) hose

to welding power source water-in

connection.

NOTICE

−

If welding power source

has a water valve, do not connect

hoses to water valve.

8

Water-Out (To Torch)

Connection

Connect torch water-in (blue) hose

to welding power source water-out

connection.

Operation:

9

115 VAC Cord

10 Flowmeter

To turn cooling unit On, connect

power cord to welding power

source 115 volts AC receptacle.

Unplug to turn unit Off.

Flow indicator spins to indicate that

at least 1.1 qt/min (1.0 L/min) of

coolant is flowing.

1

3

5

6

7

2

8

9

4

10

Summary of Contents for Cool Runner 3CS OM-230 161 F

Page 4: ......

Page 18: ...TM 216 869 Page 14 Dynasty 350 700 Maxstar 350 700 Notes...