Operator's M

anual: Millereek 6700P & 8700P PT

O Spreaders

SECTION 4: MAINTENANCE & ADJUSTMENT

Guidelines

for Regular Maintenance

WARNING:

All shields must be replaced after maintenance or adjustment procedures are

Ah

performed. Failure to do so could result in serious personal injury or death.

Performing regular maintenance on you Millcreek Spreader will help ensure optimal performance.

Please follow these guidelines for maintaining your spreader:

•

Clean the spreader once a week and before storing the unit for an extended period oftime.

ATTENTION:

NEVER store manure in the spreader between unloading times during

criticalcoldweathermonthswhenafrozenloadcouldresultinsevereequipmentdamage

(i.e. tom floor apron chain). Storing wet manure in the spreader( or keeping the spreader

outdoorswithmanureinit)willacceleraterustingofthesteel.

•

Check the spreader each time it is used for loose, bent, broken or missing parts.

ATTENTION:

During operation, listen for abnormal soundswhichmightindicate loose

parts or other equipment damage. Correct anypartsproblems immediately; expanded parts

views of all spreader assemblies are provided in the Appendixes at the back ofthis manual.

ATTENTION:

For safe and proper operation of the spreader, adhere to the following

specifications fortightening the hitch hardware; failure to tighten all hitch hardware securelymay

result in equipment damage.

Hardware

Torque5Specification

1/2"°

60 ft. lbs.

3/8"

25 ft. lbs.

5/16"

15 ft. lbs.

•

Check and grease the lube fitting at the PTO (at the front of the spreader) once a year. Remove the

telescoping shaft, clean, and add alight coating of grease.

•

Check that implement tires have adequate air pressure (30 psi). Wheel bolts should be torqued to

7 5 to 80 ft. lbs.

•

Inspect the safety chain regularly to check the condition of the links and locking/hooking

mechanisms; replace the chain as soon as weakness/breakage is noted.

•

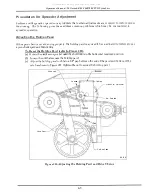

Periodically check the belt tension. Refer to the

Front Drive Assembly Parts Detail

in

Appendix A at the back ofthis manual to locate the belt tension components. The belt and

tensioning spring are located under the front belt shield. As needed, re-tension the belt by tightening

the eyeboltuntil the spring stretches to five ( 5) inches.

•

Apply chain lube once a month to the drive chains (showninFigure4B); use vegetable oil or a

common spray lube for chains.

4-1

All manuals and user guides at all-guides.com