WARNING:

Do not use the proportioner

where water pressure exceeds

90 psig (620 KPa). Do not use

the proportioner with a water

supply temperature above

170°F (77°C). Use caution

when handling chemicals;

wear protective eyewear and

gloves to prevent contact with

the chemicals. Failure to follow

these instructions may result in

personal injury.

For more specific information

on the safety of the various

CIMCOOL metalworking flu-

ids, obtain the Product Infor-

mation Folder(s) and follow the

recommendations provided.

CIMCOOL MIX MASTER

PROPORTIONER

II

®

965621

Rev. D 9/08

Publication No. PC554-8

3000 Disney Street

Printed in U.S.A.

9/08

Milacron Marketing Company

Cincinnati, Ohio 45209

888-246-2665

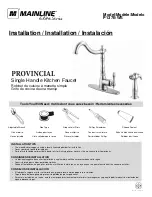

FIGURE 2

CIMCOOL Mix Master

II

Proportioner (EQ02549) Parts, Exploded View

KEY

ITEM NUMBER

DESCRIPTION

1

EQ00151

Strainer Washer (238100)

2

EQ00160

Hose swivel (506500)

3

EQ00078

Ball valve (502000)

4

EQ00159

Street Elbow (505600)

5

EQ00162

Nipple (505900)

6

EQ00074

Vacuum Breaker (506300)

7

EQ02246

Mounting Bracket (6150-K)

8

EQ02862

Bung Adapter Assy. (Plastic)

(90083030, 90083031, 90083032)

9

EQ00144

Metering Tip Kit (690015)

10

EQ00075

Orifice Retainer (441101)

11

EQ00142

Venturi (Eductor Body) Assy. (441100-CM)

12

EQ00082

Discharge Hose Assy. (5058-4DA)

13

EQ00168

Siphon Hose/Foot Valve Assy. (5058-4DM)

14

EQ00143

Foot Valve Assy. (10076305)

Part Number EQ02549

UPC 66250502549

OPERATING INSTRUCTIONS/INSTALLATION GUIDE

D E S C R I P T I O N

The CIMCOOL Mix Master

II

is a

simple, economical, and accurate

method to mix CIMCOOL metalworking

fluid concentrate with water. The most

important requirement in the use of

metalworking fluids is maintaining the

proper mix ratio. The Mix Master

II

siphons concentrate from a 55 gallon

or ( 200 L) drum and mixes it with water

to supply approximately 3 to 4* gallons

per minute of premixed fluid for an

individual machine tool reservoir, central

system, or premix tank. This is

accomplished by a siphoning venturi

operating on water pressure.

The two main requirements for

successful operation of the equipment

are a minimum water pressure of 15

psig (101 KPa) (flow pressure) and

selection of the proper metering tip.

The unit features a vacuum breaker to

prevent backflow of fluid concentrate to

the tap water line (in compliance with

OSHA regulation 29 CFR section

1910.141 (b)(2)(iii)).

The unit also features a foot valve/

strainer to prevent backflow of

concentrate into the drum.

* 3.7 gpm at 40 psig flow pressure (14 LPM at 275 KPa)

14

13

12

9

10

11

7

8

1

2

5

6

4

4

3

5

4