6.Shutdown

To stop the engine in an emergency, turn the stop

switch to the OFF position.

Under normal conditions, use the following

procedure:

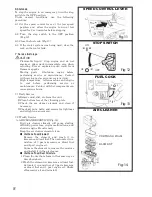

6-l Set the speed control lever at the low speed

position and allow the engine to run at low

speed for 2 or 3 minutes before stopping.

6-2 Turn the stop switch to the OFF position

(Frg-12)

6-3 Close the fuel cock. (Fig-13)

6-4 If the water system was being used, close the

cock on the water tank.

7. Service & storage

CAUTION

Flammable liquid

:

Stop engine and do not

smoke or allow work in immediate area when

refueling. Fire or explosion could result from

flames or sparks.

Moving parts

:

Shutdown engine before

performing service or maintenance. Contact

with moving parts can cause serious injury.

High temperature

:

Allow machine and engine

to cool before performing service or

maintenance. Contact with hot components can

cause serious burns.

7-l Daily Service

A.Remove mud, dirt, etc.,from the unit.

B.Clean bottom face of the vibrating plate

C.Check the air cleaner element and clean if

necessary.

D.Check all nuts, bolts, and screws for tightness

and retighten as necessary.

7-2 Weekly Service

A.AIR CLEANER SERVICE (Fig-14)

Dirty air cleaner element will cause starting

difficulty, power loss, engine malfunctions, and

shorten engine life extremely.

Keep the air cleaner element clean.

●

Urethane Foam Element

Remove the element and wash it in

kerosene or diesel fuel. Then saturate it in a

mixture of 3 parts kerosene or diesel fuel

and I part engine oil.

Squeeze the element to remove the mixture

and install it in the air cleaner.

●

Urethane Foam Dual Structure

1.Clean the urethane foam in the same way as

described above.

2.Wash the element in kerosene or diesel fuel.

Saturate it in a mixture of 3 parts kerosene

or diesel fuel and 1 part engine oil. Shake

off excessive oil and reinstall.

SPEED CONTROL LEVER

Fig-11

STOP SWITCH

ON

OFF

Fig-12

FUEL COCK

Fig-13

AIR CLEANER

ELEMENT

URETHANE FOAM

Fig-14

8