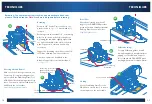

A

B

C

F

D

E

Congratulations on your purchase of the

GRR-RIPPER 3D PUSHBLOCK system.

We have put a lot of thought and effort into designing and making what we believe

is the safest, most precise pushblock available. Before using your GRR-RIPPER, read

through this booklet to familiarize yourself with the GRR-RIPPER and how it works.

Here is a general overview of the way the GRR-RIPPER was designed to work:

Green GRR-RIP

®

•

The GRR-RIPPER uses grooved

non-slip pads (Green GRR-RIP

®

) to

hold down and feed your workpiece

through the cutting element . The tool

can be rotated end-to-end to for use

with either the 1/2” or 1/4” Side Leg

against the fence .

•

With the rip fence set parallel to the

saw blade, the GRR-RIPPER glides

against the rip fence to ensure a

parallel feed . It also keeps both sides

of the workpiece in their original

positions throughout the cutting

process, which virtually prevents the

possibility of kickback and burning .

With bare-hand feeding eliminated,

finger injury is greatly reduced .

•

The GRR-RIPPER feeds the workpiece

as the saw blade passes through

either its right or left tunnel . This

feature provides protection to both

hands of the user . The GRR-RIPPER is

a protective blade-cover that the user

holds regardless of movement .

WARRANTY REGISTRATION

Each MICROJIG product includes a one year manufacturer’s warranty. Please mail in

the provided registration card or complete the registration online at

MICROJIG.com/support/warranty-registration/

RECEIVE THE MICROJIG E-NEWSLETTER

Get our free whitepaper on “4 Easy Ways to Tune-up Your Table Saw” by signing

up for the MJ INSIDER. Join the smartest woodworkers worldwide today. Go to

MICROJIG.com/newsletter

and enter your email address.

Work smarter.

INTRODUCTION

INTRODUCTION

4

5

GRR-RIPPER

glides against

rip fence

A

B

C

D

E

F

The Adjustable Handle can be relocated directly above the cut-line, providing

balanced and concentrated pressure .

The height adjustable Balance Support

accommodates different thicknesses

of stock .

The adjustable Center Leg precisely

supports different widths of cuts, providing

unique control of both sides of stock .

Wooden riser spacers can be added for

use with stock thicker than 2” .

Attach with #8 pan head wood screws

and washers (not included) .

A wooden spacer can also be added between the GRR-RIPPER and the fence to

increase the cutting width capacity of the GRR-RIPPER .

Fully adjustable GRR-RIPPER controls wood of different widths and thicknesses .

Adjustable design for your project needs.

Reversible

3

1

2