Quick Reference Guide

for Windows 7, Vista, and XP

Rev 10.03.26

Please visit our Technical Support website at www.microboards.com/support

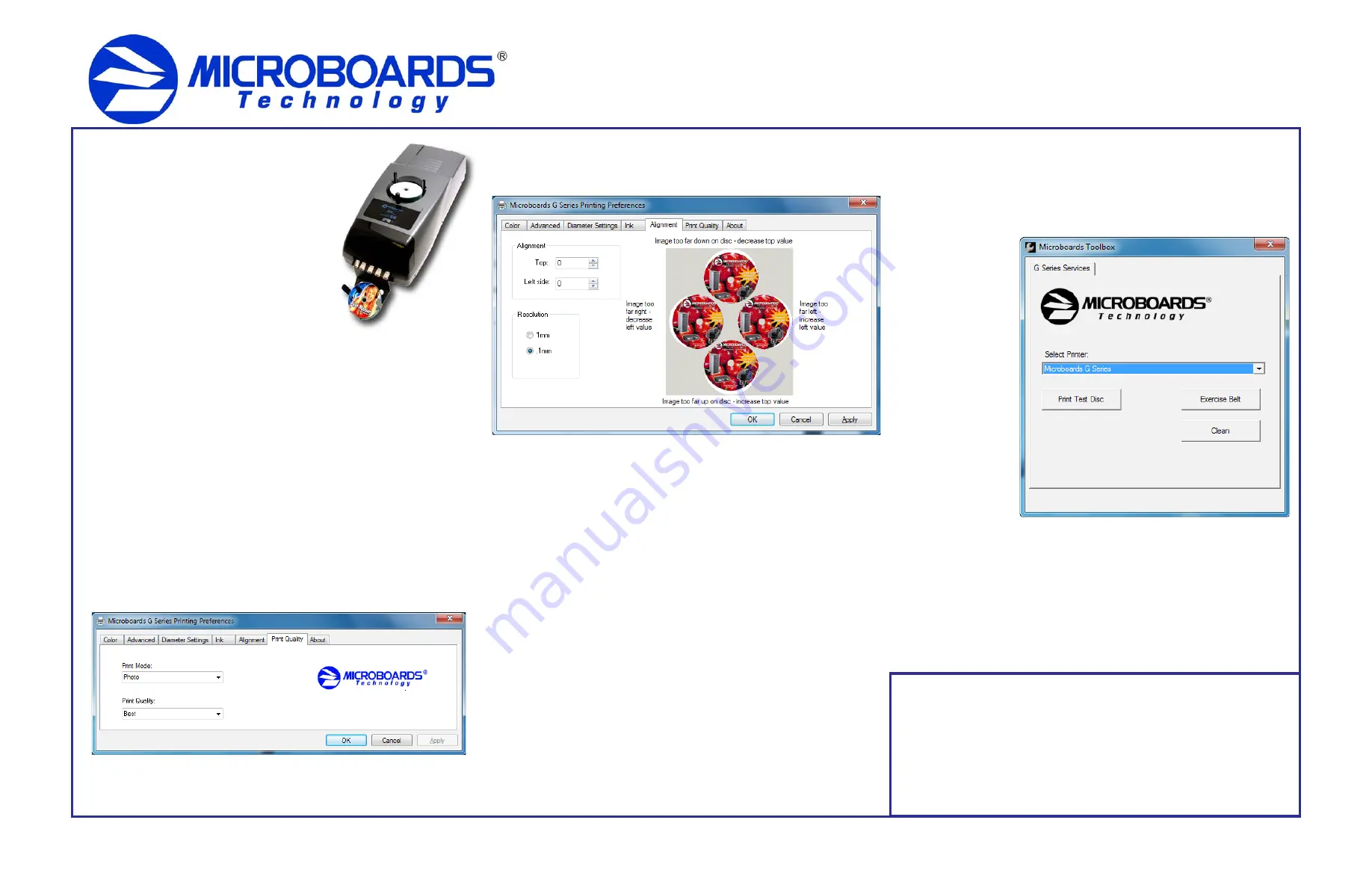

GX Auto Printer Alignment

Your GX Auto Printer has been factory aligned to .1mm

precision. The values provided with the GX Auto Printer,

located on the back of the unit below the power plug,

are the offset values to be used in the Printing

Preferences.

To set these values, please follow the steps listed

below:

1.

Access the Printing Preferences for the

Microboards G Series. How this is done will depend

on the Operating System and the currently selected

Start Menu layout.

Windows 7:

Select

Devices and Printers

from the

Start

button.

Windows Vista:

Select the

Control Panel

from the

Start

button. Once the

Control Panel opens, select

Printer

from the

Hardware and Sound

section.

Windows XP, Classic Start Menu layout:

You will need to go to the

Settings

selection, then to the

Printers and Faxes

from the

Start

button.

Windows XP, Start Menu layout:

Select

Printers and Faxes

from the

Windows Start

button.

2.

Right click on the icon for the

Microboards G Series

and select

Printing

Preferences…

3.

On the

Print Quality

tab, select

Photo

for the

Paper Type

and

Best

for the

Print Quality

.

Photo Best

should

always

be selected when aligning the printer, in order to

insure the greatest accuracy during the alignment process. Other settings

may not result in the best alignment.

4.

Select the

Alignment

tab. The

.1mm

Resolution

setting must be selected

before setting alignment values (see below). Set the

Top

and

Left Side

alignment

values to those required for image alignment.

These settings will change the size of the top and left margins, respectively.

Decreasing the values will move the image up or to the left, increasing will

adjust down or to the right.

5.

Click the

Apply

button to save the changes, found on the bottom of the Printing

Preferences window.

6.

Start the SureThing application. Select a pre-designed full-coverage SureThing

disc image.

Place an blank disc in the input hopper and print the disc.

Remember, Photo

Best mode should always be used when aligning the printer for the highest

accuracy.

7.

Check the printed disc. If the settings are correct, the image should be centered

on the disc. If not,

repeat steps 4 through 7

, changing the

Top

and

Left Side

amounts, using the graphic guide to the right of the alignment settings as a

reference to how the values should be changed.

8.

Fine tuning may be required for different brands and can be done within the

printing application to avoid altering these global alignment values set in the

Printer Properties.

For further details on the alignment process, please refer to the

section on Alignment in the GX Auto Printer User’s Manual.

GX Auto Printer Configuration

COLOR INK CARTRIDGE CAN BE USED!

As is true with all printers, the quality of ink cartridge and the quality of the ink

within the cartridge will affect your output. To ensure quality results, the GX Auto

Printer will not operate with any other color ink cartridge in place.

The use of refilled ink cartridges will void your warranty!

ONLY MICROBOARDS GX-300HC

In order to guarantee quality results from the GX Auto Printer,

G Series Toolbox

Double-click the icon for the Microboards Toolbox that was placed on your PC’s

desktop during the installation process. The Test and Clean disc functions require

blank media be loaded before the buttons are clicked.

Clicking the

Test Disc

button prints out a test

pattern to verify the

printer is functioning.

The

Exercise Belt

utility should be run if

the printer has been

idle for an extended

period of time, and can

be run multiple times if

necessary. The belts

will run at high speed

for a period of time to

recondition the belts. It

is not necessary to

load any media for this

utility.

Clicking the

Clean

Disc

button prints out a

heavy ink-usage pattern

to clear any clogged ink

nozzles.

Be sure your computer meets the Minimum System Requirements as stated

in the User’s Manual and that you have read these instructions and the

Manual prior to contacting Microboards Technical Support with installation

or configuration questions!