10

EN

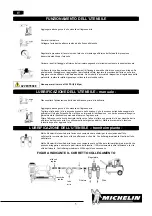

CLEARING A JAM FROM THE TOOL

FASTENER JAMMED IN FASTENER DISCHARGE AREA:

Disconnect air tool from air hose.

Open the nozzle part, grab jammed fastener with pliers and remove.

FASTENER JAM INSIDE MAGAZINE:

Disconnect air tool from air hose.

Pull back on the magazine cover.

Open the nozzle part and remove jammed fastener.

Push the magazine cover forward until the latch catches.

CLEANING THE TOOL

WARNING

Disconnect the air supply from the tool before cleaning and inspection. Ensure all parts are clean and re-

assembled properly before using the tool again.

DANGER

NEVER USE GASOLINE OR OTHER FLAMMABLE LIQUIDS TO CLEAN.

THE TOOL. VAPORS IN THE TOOL IGNITE BY A SPARK AND CAUSE THE TOOL TO EXPLODE AND RESULT IN

DEATH OR SERIOUS PERSONAL INJURY.

Disconnect the air supply from the tool.

Remove tap build-up with kerosene #2 fuel oil or fuel. Dry off tool completely before use.

NOTE

DO NOT SOAK tool with cleaning solutions, or damage may occur.

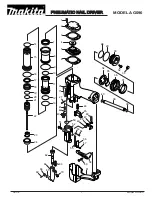

REPAIRING THE TOOL AND TROUBLE SHOOTING

SERVICE AND REPAIRS

All quality tools will eventually require servicing or replacement of parts due to wear from normal use. These operations should ONLY be

performed by a licensed professional technician. Never try to repair the tool by yourself.

TROUBLE SHOOTING

WARNING

Disconnect tool from air supply before performing any service procedure.

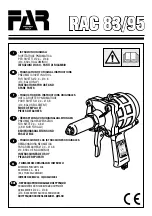

SYMPTOM PROBLEMS

SOLUTIONS

1

Air leak near top of tool or in trigger

area.

Loose screws.

Worm or damaged o-rings or seals.

Tighten screws. Install overhaul kit.

2

Tool does nothing or operates

sluggishly.

Inadequate air supply.

Inadequate lubrication.

Worn or damaged o-rings or seals.

Verify screws. Install overhaul kit.

3

Air leak nears bottom of tool.

Loose screws.

Worn or damaged o-rings or seals.

Tighten screws. Install overhaul kit.

4

Tool jam frequently.

Incorrect fasteners.

Damaged fasteners.

Magazine or nose screw loose. Magazine

is dirty.

Verify fasteners of correct size. Replace

w/undamaged fasteners. Tighten screws.

Clean screws.

5

Other.

Contact your local dealer for service.