6. USING THE CROWCON TETRA 3 GAS

DETECTOR

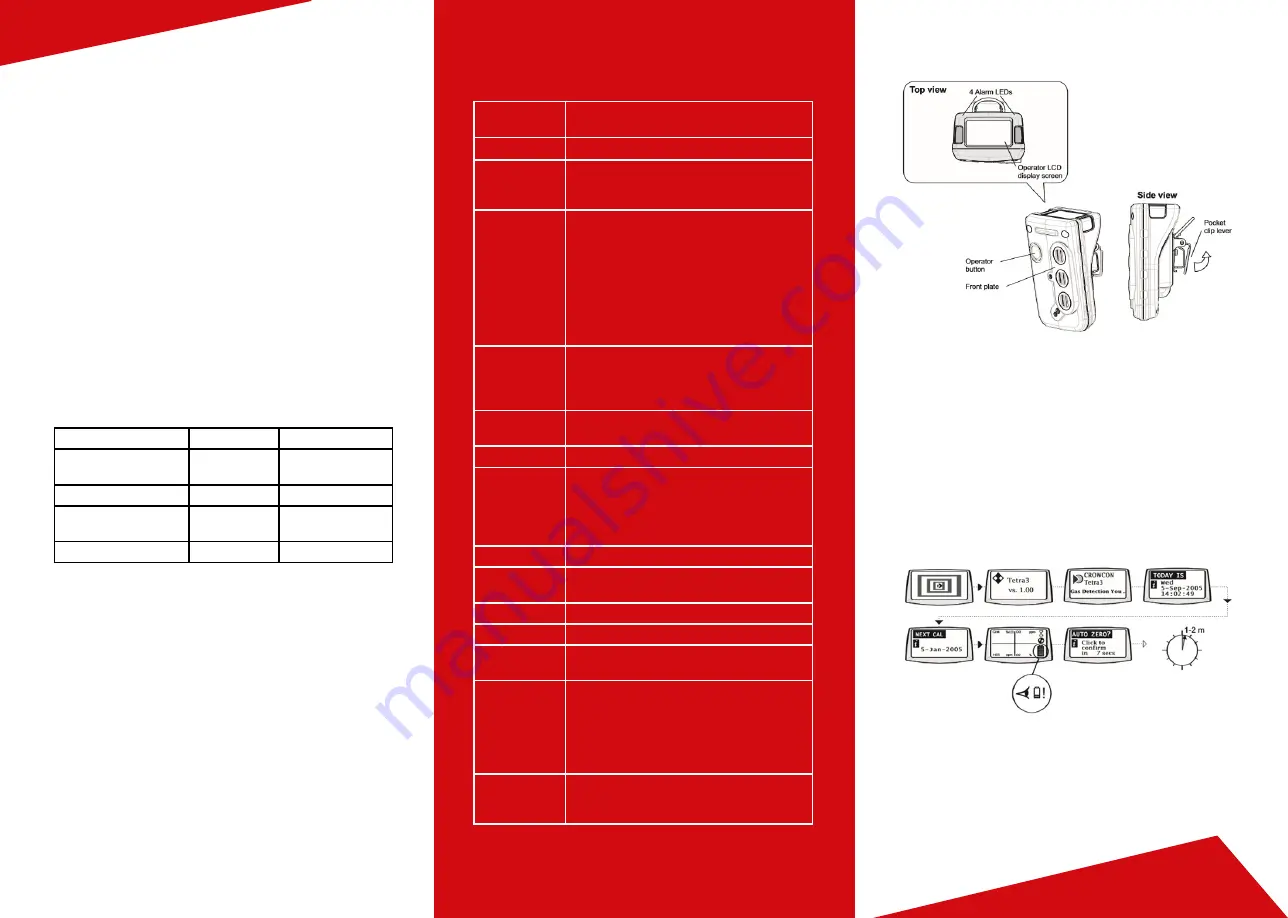

Switching on your unit

1)

Ensure the unit is in clean air.

2)

Switch on – Press and hold the operator button until the

red LED flashes. The operator display will light up and the

unit will begin a warm up sequence.

3)

The unit will test the alarm LEDs, sounder, vibration alerts,

and the operator display screen. The sounder may be

silenced by pressing the button.

4)

The unit will continue through a warm up sequence as

shown below, this will take approximately 45 seconds.

5)

If auto zero is enabled (default), the unit will display the

auto zero menu. Press the operator button with a single

click to confirm auto zero. If the operator button is not

pressed within the 10 second time out, Tetra 3 will proceed

directly to Run mode without performing zero.

1. IMPORTANT NOTES

•

For the use of MGF supplied equipment only.

•

Ensure users are fully trained in the operation of this

equipment and a site specific safe system of works is

in place and adhered to.

•

It is essential that site specific risk assessments are

undertaken.

•

Do not try to modify or change the equipment in any

way as this could void any warranty or cause damage

to equipment or persons using it.

•

If in doubt concerning the integrity of any part of the

equipment DO NOT USE IT

2. CROWCON TETRA 3 GAS DETECTOR

•

The Tetra:3 multi-gas monitor is a compact, robust and

easy-to-use diffusion based detector. Single button

operation, small size and clear top-mounted display make

it a favourite in the market amongst those working in

demanding industrial environments; such as those in the

water, telecoms, food, brewing or hydrocarbons sectors.

3. GASES AND RANGES

•

While these are the standard gases we use, we have the

ability to provide detection for other gases, please speak to

the MGF Safety Department for further details.

4. MGF EXAMINATION AND TESTING

•

Upon return to MGF the equipment will be cleaned,

inspected and function tested by a competent and trained

MGF safety technician.

5. VISUAL INSPECTION/FUNCTIONAL TEST -

PRIOR TO USE

•

Before the start of each use ensure that the equipment is

clean and free from debris and there are no obvious defects.

•

Ensure that the item has a green tag, stating when it was

last inspected.

•

Each item comes with a unique ID number, please ensure

this can be found.

Size

114 x 71 x 48mm (tapers to 20mm) (4.5 x 2.8

x 1.9ins)

Weight

295g (10.4oz)

Alarms

95dB multiple alarm sounds allow selection

of distinctive tones for different alarm

levels. Internal vibrating alarm

Display

Graphic LCD with backlight, giving simulta-

neous display for all gas channels. Graphic

symbols for battery (with proportional

indication of remaining operation time),

healthy operation or fault warning. Start-up

indication when calibration is due, over-

due, or service required. Normal display:

Real time gas concentration levels. Display

recall: Peak readings and TWA

Data Logging

Timed: 50 hours at 1-minute data rate

(>12,000 data logs of 4 channels) Threshold:

Starts after adjustable pre-set level

Event: >5,000 events

Event Logging

Alarm, over range, calibration, bump, on/off,

TWA, 1000 events

Battery

Rechargeable Li-ion battery

Operating

Time

Based on four-gas instrument fitted with

flammable sensor: A 5-hour charge from

flat provides at least 12 hours of continuous

use. A 12-hour charge provides at least 14

hours of continuous use

Sampling

Diffusion or hand aspirator

Operating

Temperature

-20°C to +55°C (-4°F to +131°F)

Storage

-25°C to +65°C (-13°F to +149°F)

Humidity

20 to 90% RH

@

40°C non-condensing

Ingress

Protection

IP65 and IP67

Approvals

ATEX II 2 G Ex ia d IIC T4 Gb (-20°C ≤ Ta ≤

+55°C) BASEEFA05ATEX0187

IECEx Ex ia d IIC T4 Gb (-20°C ≤ Ta ≤ +55°C)

BAS05.0059

CSA Class I Division 1 Groups A, B, C and D

Safety

Standards

EN60079-0, EN60079-11, EN60079-1,

CSA22.2, 152, EN50270, EN50271, EN50104,

EN45544, EN60079, IEC61508

Specifications

Gas

Range

Typical Alarms

Flammable

(Methane)

0-100% LEL

20%

Oxygen (O²)

0-25%

19/23.5%

Hydrogen Sulphide

(H²S)

0-100ppm

5ppm

Carbon Monoxide (CO)

1-500ppm

30ppm

mgf.ltd.uk