Petrol Powered Back Pack Blower

9

or damaged, clean the filter with warm water and mild detergent and allow to dry, or fit a new one. Place a

few drops of oil on the air filter element and squeeze it a few times to distribute the oil.

•

Install the filter element and re-install the air filter cover.

Carburettor

Your carburettor comes factory set for optimum fuel-air mixture under most operating conditions.

The high speed screw alters the engine power output and the maximum unloaded engine speed. If the setting is

too lean, there is a risk of engine damage due to insufficient lubrication and overheating.

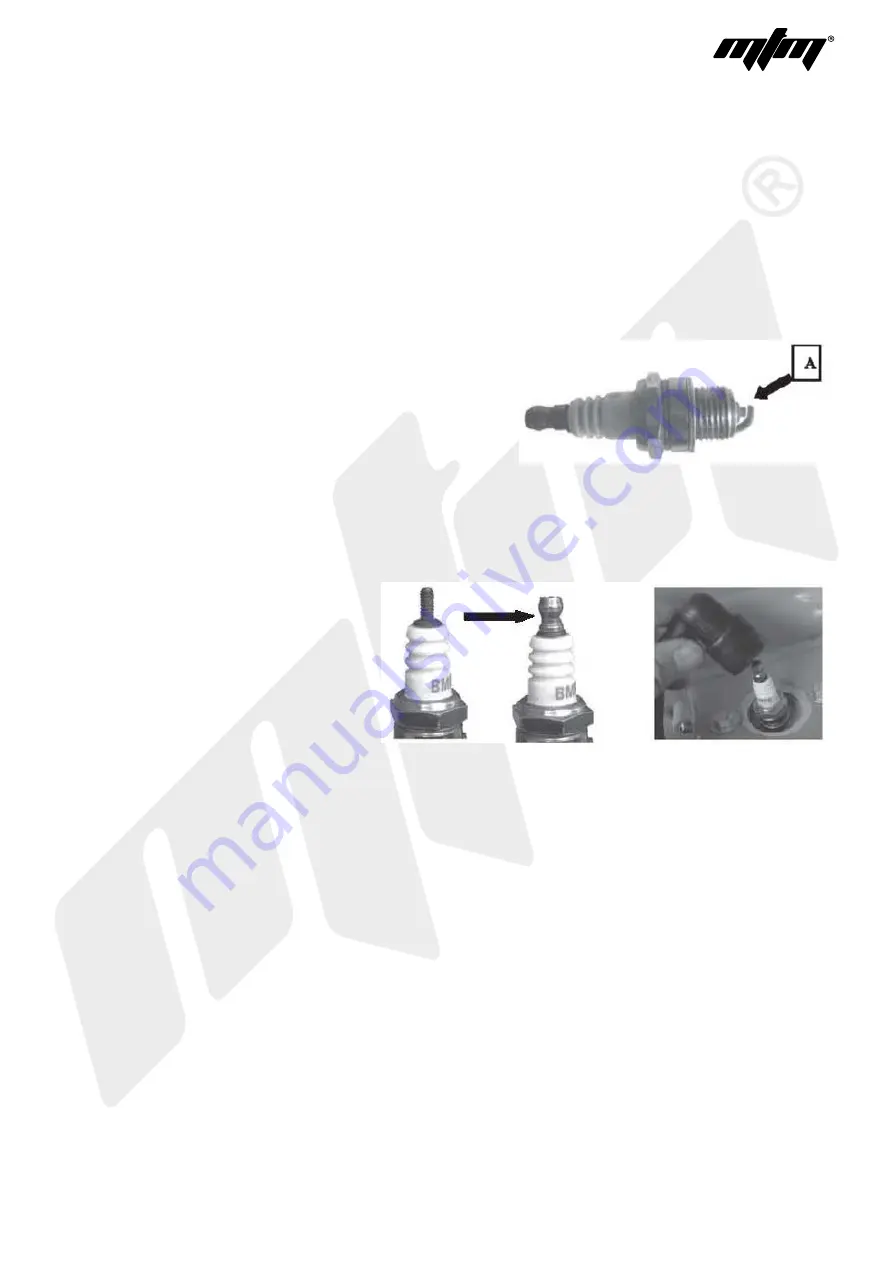

Checking the Spark Plug

If engine is down on power, difficult to start or runs poorly at idle

speed, first check the spark plug.

•

Remove the spark plug using the supplied spanner and

clean off any carbon build-up with a wire brush.

•

Check the electrode gap (A) (0.6 – 0.7mm) and adjust if

necessary.

•

Rectify any problems which may be affecting the spark plug:

−

Too much oil in fuel mixture (oily electrodes).

−

Dirty air filter.

Fit a new spark plug after about 100

operating hours, or sooner if the electrodes

are badly eroded.

•

If the spark plug comes with a

detachable connector, firmly tighten it.

•

Press the cap firmly onto the spark plug.

Engine Running Behaviour

If engine running behaviour is unsatisfactory even though the air filter is clean and the carburettor properly

adjusted, the cause may be in the muffler. Have the muffler checked for carbon build-up by the manufacturer or

an authorised service centre.

Storing the Machine

For periods of 3 months or longer:

•

Drain the fuel tank.

•

Run the engine until carburettor is dry. This helps prevent the carburettor diaphragms from sticking together.

•

Thoroughly clean the machine. Pay special attention to the cylinder and air filter.

•

Remove the spark plug and pour approximately 20ml of engine oil into the cylinder. Slowly pull the start cord

several times, then re-install the spark plug.

•

Store the machine in a dry, secure location out of the reach of children and unauthorised persons.