10

2 L6 70 en

If the reason for the leakage does not become apparent

after doing the above, the valve must be disassembled for

replacing the parts.

5.5

Replacing the seat ring

Ensure that the valve is not pressurized.

Remove the valve from the pipeline. The valve must

be in a closed position during removal.

Follow the lifting methods shown in Section 3.

5.5.1

L6C, L6D, L6F/D and L4F/D

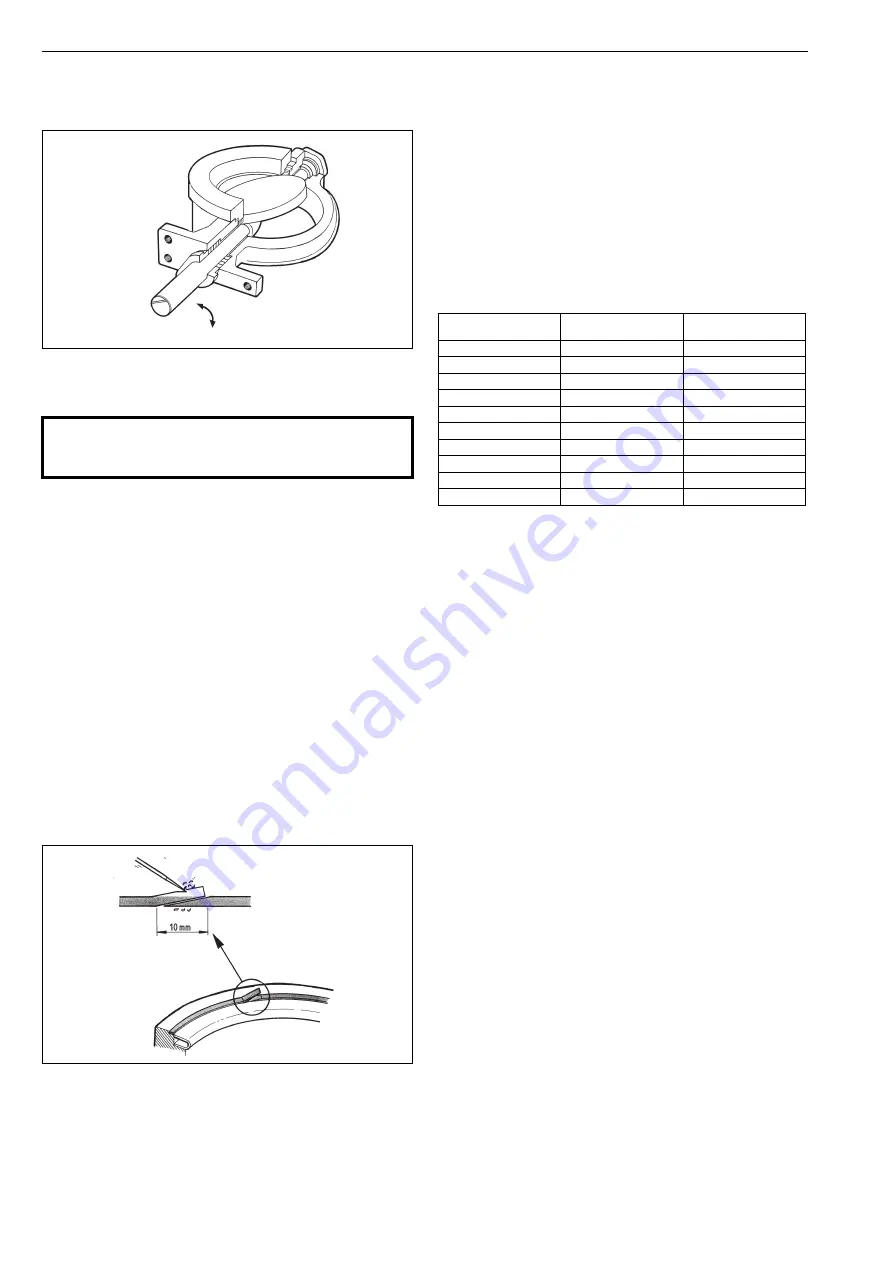

Remove the clamp ring (2) by untightening the

screws (27).

Remove the old body seal (19) and the seat ring (4).

Change the seat ring if it is damaged.

Clean all the surfaces of the seats and check the sur-

face of the seat ring.

Check also the condition of the disc. A damaged disc

must be changed (see Section 5.6).

Check the condition of the pin connection. Repair it

if necessary (see Section 5.6).

Mount a new, self-adhesive body seal (19) into the

body. The surface must be clean and free of grease.

Handle the ends of the seal according to Fig. 15.

Spray a thin layer of dry lubricating fluid, e.g.

Molykote 321R or equivalent, into the seat groove,

surfaces of the clamp ring, seat ring and screws.

Centre the seat ring (4) carefully into its groove and

turn the disc to maintain light contact with the seat.

Mount the clamp ring and tighten the screws (27)

lightly.

Turn the disc slightly open and pull it back to set the

seat into the proper position.

Tighten the screws (27) crosswise and evenly. First to

50 % of recommended torque, then to 100 %.

Recommended torque values for screws are listed in

Table 10. An unevenly tightened flange may damage

the seat ring. The screw heads must be below the

flange surface in lug type valves.

Check the position between the seat ring and the

disc. The valve closes clockwise (see Fig. 14).

Mount the actuator into the valve. Adjust the closed

position limit and check the open position limit (see

Section 6).

5.5.2

L6F

Remove the clamp ring (2) and the old seat ring (4).

Clean up graphite from the body groove.

Polish the contact surface of the new body seal with

emery paper (grade 240). Also polish the edge of the

disc.

Spray a thin layer of dry lubricating fluid, e.g.

Molykote 421R, to the edge of the disc.

Mount a new graphite body seal (19) to the body

and then the seat ring (4).

Mount the clamp ring (2). Tighten the screws (27)

lightly, so that the seat ring (4) is still moveable.

Ensure that the valve is well supported on a stable,

horizontal surface.

Turn the disc with a suitable lever to the horizontal

(=fully closed) position. Lock the lever to this posi-

tion, e.g. using a lifting crane, to prevent the disc

moving in the open direction. See Fig. 16.

Tighten the screws (27) crosswise, see Table 10 for

recommended torques.

Operate the disc to the open position and check the

contact between the seal and the disc. The trace left

in the disc by the seat should be continuous around

the disc. If not, remount the seat ring.

Fig. 14.

Open and closed positions of the valve

CAUTION:

Do not dismantle the valve or remove it from the pipe-

line while the valve is pressurized!

Fig. 15.

Mounting the body seal

open

closed

Table 10.

Clamp ring/blind flange screw torque, Nm ±10 %

Thread

mm / (UNC)

Clamp ring

Blind flange

M6, 1/4

14

11

M8, 5/16

19

15

M10, 3/8

38

29

M12, 1/2

66

51

M16, 5/8

160

123

M20, 3/4

310

240

M22, 7/8

420

324

M24, 1

540

416

M32, 1 1/4

1430

1100

M38, 1 1/2

2380

1830

Summary of Contents for NELDISC L4 Series

Page 34: ...34 2 L6 70 en ...

Page 35: ...2 L6 70 en 35 ...