7

B. Apply silicone grease to the end-cap o-ring seals,

using the recommended o-ring-area grease listed

in

(Table 2)

. Fit the end-cap o-ring seals (14) into

the groove in each end cap (30, 31).

C. Fit the end caps (30, 31) onto the body (50),

verifying that the o-ring seals (14) remain in the

grooves.

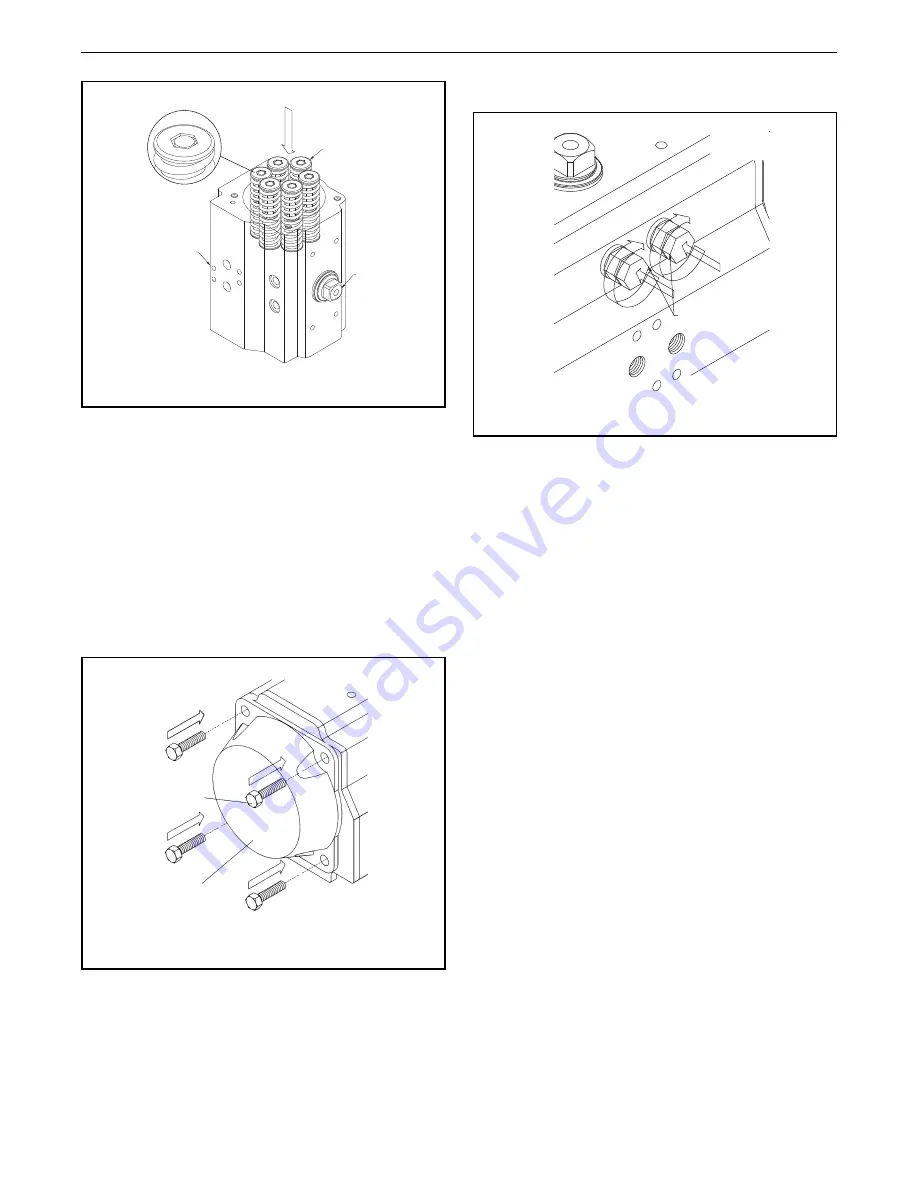

D. Insert all end-cap screws (13) and hand tighten.

Complete tightening by following the sequence

indicated in

(Figure 16)

.

4. Assembly of Stop Screws (2) and Stroke

Adjustment. (Figure 17):

A. Insert the nut (4), washer (3), and o-ring (11) onto

the stop screws (2).

B. Screw the stop screws (2) into the body (50).

5. External Travel Stop Adjustment, (Figure 17):

The stop adjustment screw (2) to the right controls the

clockwise end of travel. The stop adjustment screw (2) to

the left controls the counter-clockwise end of travel.

A. Cycle the actuator/valve to the clockwise end of

travel and measure to determine if the valve is in

the proper position. (In most applications this

will be fully closed.)

B. If the valve is not in the correct clockwise position,

turn the right stop adjustment screw (2) IN to

reduce actuator travel, or OUT to increase actuator

travel.

C. When the correct clockwise position is obtained,

hold the adjusting screw (2) stationary while

tightening the lock nut (4).

D. Cycle the actuator/valve to the counter-clockwise

end of travel and measure to determine if the valve

is in the proper position. (In most applications

this will be fully opened.)

E. If the valve is not in the correct counter-clockwise

position, turn the left stop adjustment screw (2)

IN to reduce actuator travel, or OUT to increase

actuator travel.

F. When the correct counter-clockwise position is

obtained, hold the adjusting screw (2) stationary

while tightening the lock nut (4).

6. Position Indicator (19, 39) Assembly. (Figure 18):

A. Fit position indicator (19) on the shaft (60),

verifying that it indicates the correct actuator

position.

B. Tighten cap screw (39) to secure the position

indicator.

Figure 16

3

13

1

30, 31

4

2

Figure 17

2, 3, 4, 11

Figure 15

60

17

50