IMO-227 EN

7

IMO 8/17

5. If the valve has the “leak-off” option, remove any

remaining “leak-off” port fittings or plugs.

6. The insert design requires that the insert (2) be

unthreaded in a counter clockwise motion using the

following method utilizing the insert field wrench.

Assemble the field wrench as follows (see Figures 5

and 19):

a. Place the driver (A) into the insert (2) slots.

b. Put the plate (C) on top of the driver (A).

c. Place the studs (E) through the plate (C) and flange

holes. Thread the nuts (F) onto the stud below the

flange.

d. On the top side of the plate (C) put a flat washer (G),

die spring (H), flat washer (G), and nut (F). Tighten to

slightly compress spring

7. Place a pipe or rod through the driver (A) and loosen

the insert (2) by turning counterclockwise.

8. Remove the tool and lift out the insert (2).

9. Place the valve in the vertical position with the insert

end up.

10. Rotate the stem so that the ball is in the closed position

for removal. If the ball (3) does not swing free from the

body, with the ball in the fully closed position, use a

piece of wood or some other soft material to gently

tap the ball (from the end opposite the body cap). This

should loosen the ball so that it can be pivoted free of

the steam (4). Lift out the body seal (6), seat (5), and the

ball (3). The bottom grounding spring (71), located in

bottom of the steam (4), may fall out at this time. If the

spring does not fall out with the stem, remove it from

the stem to prevent it from being lost.

11. Carefully remove the bottom seat (5) out of the body,

BEING CAREFUL NOT TO SCRATCH THE BODY

SEALING SURFACE BEHIND THE SEAT.

12. Remove the retaining ring (72) and grounding spring

(70) from stem (4).

13. Remove hex nuts (30), disc springs (31) and compres-

sion plate (20). Pay careful attention to the orientation

of the disc springs (31) and make sure they are in the

same orientation during assembly.

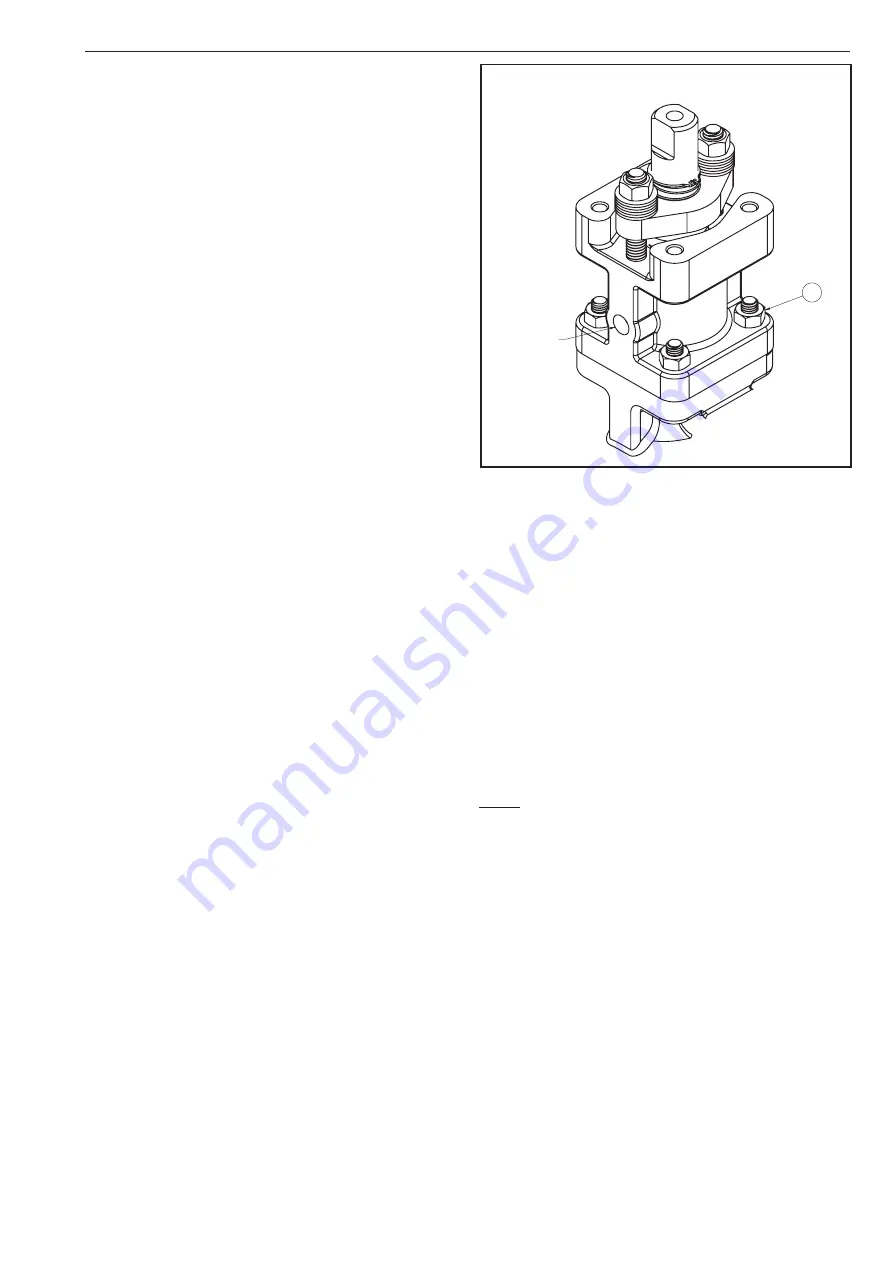

14. Remove hex nuts (111) and lift the

Emission-Pak

hous-

ing (101) straight up until the ball end of the stem

clears the valve body (1) (see Figure 6 and 20).

15. Carefully remove and discard the inner and outer stem

retainer seals (105) and (106).

16. From the

Emission-Pak

housing (101) remove the

stem (4), stem bearings (13), secondary stem seal

(7), stem seals (104), bearing strip (109) and lantern

ring (103), BEING CAREFUL NOT TO DAMAGE ANY

SEALING SURFACE.

Figure 6

4 .6

Checking Parts

1. Clean all disassembled parts.

2. Check the stem (4) and ball (3) for damage. Pay partic-

ular attention to the sealing areas.

3. Check all sealing and gasket surfaces of the body (1)

and insert (2).

4. Replace any damaged parts.

5. Replace any fastener where the threads are damaged

or have been heated, stretched or corroded.

6. Replace any parts that have cracks, gouges or pits that

will affect sealing.

NOTE: When ordering spare parts, always include the fol-

lowing information:

a. Valve catalog code from Identification plate,

b. If the valve is serialized – the serial number (stamped

on the valve body or indentification plate).

c.

From Figure 19 or 20, the ballooned part number, part

name and quantity required.

4 .7

Assembly – Bare Stem Valves

It is advisable to replace seats and seals if complete dis-

assembly and reassembly become necessary. Refer to the

Repair Kit chart (see Table 9A). A lubricant, compatible with

the flow media, MUST be applied to the threads on insert

(2) to prevent galling during assembly.

1. Clean all valve components if not done previously.

111

OPTIONAL

LEAK-OFF PORT

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: [email protected]