8

Operation

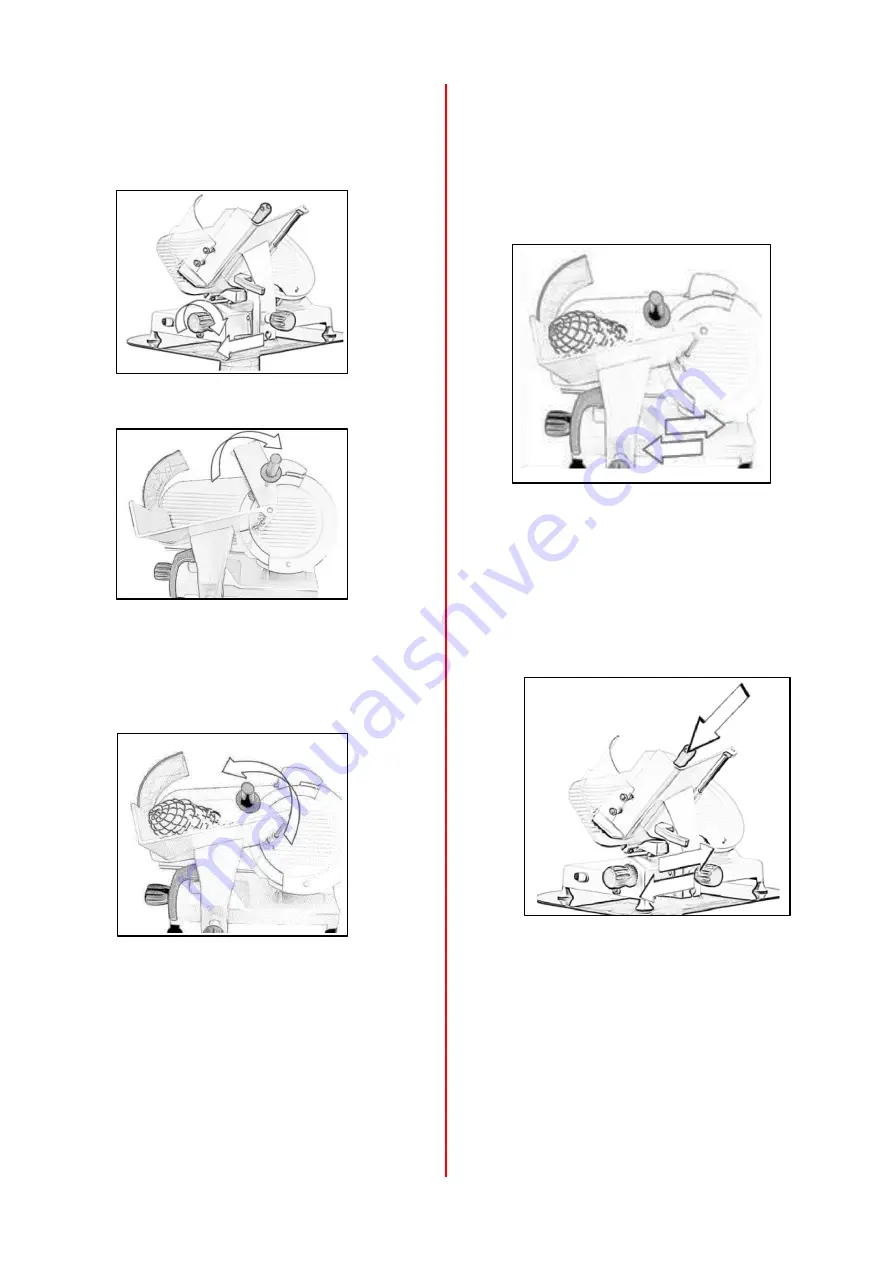

1.

Ensure the slicer is turned off and that the

thickness selection knob is set to “0”.

2.

Pull back the carriage completely (towards

the operator) to the loading position.

3.

Lift the end device up, into the rest position.

4.

Place product onto the table, the product will

press against the fence plate because of its

weight. Block it with the end device by

lowering it onto the product and pressing

down slightly.

5.

Rotate the thickness selection knob anti-

clockwise to the desired setting.

6.

Turn the slicer on by pushing the start button.

The power indicator light, which is located

between the on/off switch, will illuminate.

DO NOT hold the food product with your hand.

Never put your hand on or around the table

while the slicer is on. The end device handle is

the only part of the slicer you should touch

while slicing.

7.

Grip the handle attached to the meat table

support and manually push the carriage back

and forth. This handle and the end device

handle are the only parts of the slicer you

should touch while slicing. DO NOT catch slices

with your hands, let slices drop onto the

receiving area.

If a product needs to be adjusted during slicing,

first turn the slicer off and then pull the table

all the way towards you.

8.

When the weight or size of the product does not

allow a proper slice, use the end device handle

and apply some pressure to the product.

9.

After the last slice stroke, pull the carriage all the

way towards you. Turn the slicer off by pressing

the stop button, the power indicator light will go

out. Turn the thickness selection knob clockwise

until it stops to close the slicer table.

10.

You can now unload the product from the table.

Summary of Contents for NS250HD

Page 18: ...17 Notes ...

Page 19: ...18 Notes ...