Metal Work Spa

- Via Segni 5 - 25062 Concesio (BS) Italy

ORIGINAL INSTRUCTIONS

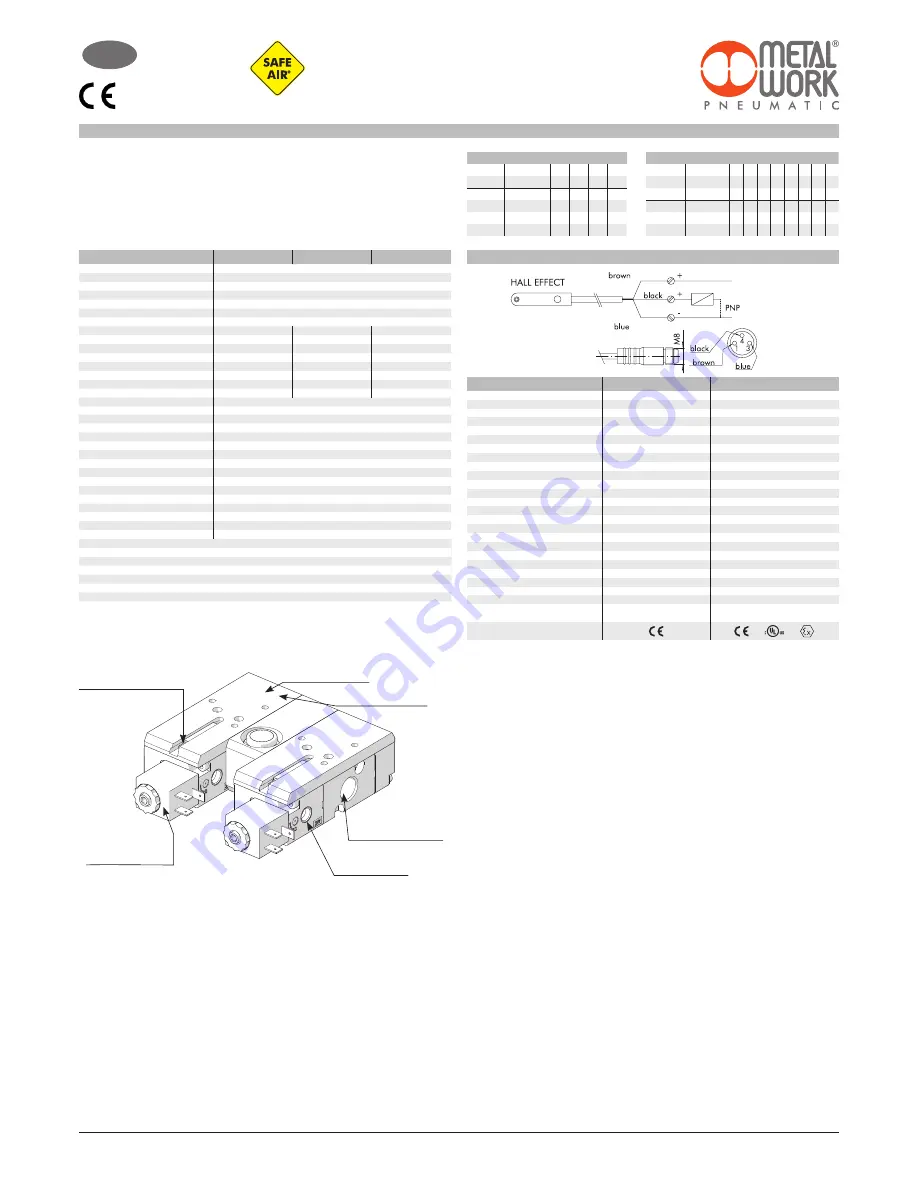

VALVE IN NON-INTERLOCKED VERSION

INPUTS

solenoid pilot 0

0

1

1

p port 1

0 1 0

1

OUTPUTS p port 2

0

0

0

1

sensor 1

1

1

1

0

sensor 2

1

1

1

0

VALVE IN INTERLOCKED VERSION

INPUTS

solenoid pilot 0 0 0 0 1 1 1 1

p interlock

0 0 1 1 0 0 1 1

p port 1

0 1 0 1 0 1 0 1

OUTPUTS p port 2

0 0 0 0 0 0 0 1

sensor 1

1 1 1 1 1 1 0 0

sensor 2

1 1 1 1 1 1 0 0

1. Designation

Control valve for cutting off the air supply and relieving the air circuit connected to port 2.

2. Description

3/2 electropneumatic monostable double valve with spool monitoring.

3. Technical data

4. Installation instructions

Proceed as follows to install the valve:

- Mount the Metal Work actuating coils on the two solenoid pilots and secure them using the ring nuts

(max torque 1 Nm).;

- connect the air pipes to port 1 of valve 1 and to port 2 of valve 2, using the pneumatic fittings provided and

following the port numbering shown on the valve;

- supply power to the coils at the rated voltage. N.B. For correct operation, the two valves must be activated

simultaneously;

- supply power to the Hall-effect sensors and connect them to the diagnostic system. N.B. For correct operation,

the reading of the two sensors must be independent;

- supply port 1 of valve 1 with compressed air;

- check operation of the valves and sensors:

- if both coils are de-energized, port 1 of valve 1 is not connected with the pneumatic circuit of downstream,

port 2 of the valve 2 discharges (port3) and both sensors are ON;

- if both coils are energized, port 1 is connected to port 2, both sensors are OFF;

- do not mount 2 or more dual SAFE AIR® valves in adjacent positions; if dual side-by-side valves are mounted,

they must be spaced at least 40 mm.

- any ferromagnetic masses must be at least 40 mm from the sensor;

- prevent magnetic fields from creating disturbance in the sensor area.

Perform consistency checks based on the following tables, which relate the valve input and output statuses:

status 0: power/signal absent;

status 1: power/signal present.

When the double valve is in the safe status (one of the spools in the home position), at least one of the sensors is

ON (1).

5. Maintenance instructions

Before carrying out any maintenance operations it is recommended to use the personal protective equipment ,

and then to remember to switch off the electricity and compressed air supplies.

Check the silencers regularly for blockage.

For maintenance operations, it is advisable to return the valve to Metal Work for the necessary repairs.

6. Instructions to prevent residual risks

- The valve must be installed by a qualified technician

- Make sure the power cables do not get damaged during operation

- Make sure the power terminals are properly connected

- Check that the pipes are inserted properly before activating the air supply

- Check that the coils and sensors are correctly wired

- Cut off the power and the air supply prior to maintenance interventions

- If the safety function (safe relief) is used less than once a month, it is advisable to conduct a monthly function test

7. Disposal instructions

The product must be dismantled and disposed of in accordance with the regulations in force in the country in which

the product is used.

TECHNICAL DATA SENSOR

Type of contact

Switch

Supply voltage (Ub)

V

Power

W

Voltage variation

Voltage drop

V

Input current

mA

Output current

mA

Switching frequency

Hz

Short-circuit protection

Over-voltage suppression

Polarity inversion protection

EMC

LED display

Magnetic sensitivity

Repeatability

Degree of protection (EN 60529)

Vibration and shock resistance

Temperature range °C

Sensor capsule material

2.5 m/2 m connecting cable

Connecting cable with M8x1

Wire NO.

Category ATEX

Certifications

ATEX

EFFECT HALL

EFFECT HALL

N.O.

N.O.

PNP

PNP

from

10 to 30 DC

from

18 to 30 DC

3

#

1.7

#

10% of Ub

#

10% of Ub

#

2

#

2.2

#

10

#

10

#

100

#

70

#

5000

1000

Yes

Yes

Yes

Yes

Yes

Yes

EN 60 947-5-2

EN 60 947-5-2

Yellow

Yellow

2.8 mT ± 25%

2.6

#

0.1 mT

#

0.1 (Ub and ta fixed)

IP 67

IP 68, IP 69K

30 g, 11 ms, from 10 to 55 Hz, 1 mm

30 g, 11 ms, from 10 to 55 Hz, 1 mm

from

-25 to +75

from

-20 to +45

PA66 + PA6I/6T

PA

PVC; 3 x 0,14 mm

2

PVC; 3 x 0,12 mm

2

Polyurethane; 3 x 0,14 mm

2

-

3

3

-

II 3G Ex nA op is IIC T4 Gc X

II 3D EX tc IIIC T135°C Dc IP67 X

WIRING DIAGRAM SENSOR

OPERATING INSTRUCTIONS

FOR VALVE DOUBLE

SERIE 70 VALVES SAFE AIR

®

GB

1/8”

1/4”

3/8”

Fluid

Filtered unlubricated air (50µm); lubrication, if used, must be continuous

Operation

3/2 monostable

Operating pressure:

bar

- non-assisted

2.5 ÷ 10

- pilot-assisted

Vuoto ÷ 10

Minimum pilot pressure

bar

2.5

Operating temperature range

°C

-10 ÷ +60 (-10 ÷ + 45 for Atex version)

Conductance C

Nl/min · bar

80

202

346

Critical ratio b

bar/bar

0.35

0.11

0.24

Flow rate at 6.3 bar ∆p 0.5 bar

Nl/min

261

561

1038

Flow rate at 6.3 bar ∆p 1 bar

Nl/min

358

778

1433

TRA/TRR at 6.3 bar

ms/ms

28/35

38/45

50/72

Conductance C on relief

Nl/min · bar

132.96

228.52

491.66

Critical ratio b on relief

bar/bar

0.27

0.21

0.21

Flow rate on free exhaust 6.3 bar

Nl/min

930

1700

3550

Installation

any position

Assembly

In line

Manual actuator

Monostable

Recommended lubricant

ISO and UNI FD 22

Compatibility with oils

See webpage www.metalwork.it/eng/materiali_compatibilita.html

Coils

22 mm side, ø 8 hole

2 W - 12 VDC, 24 VDC

3.5 VA - 24 VAC, 110 VAC, 220 VA 50/60 Hz

Certified EN 60204.1 and VDE 0580 (*)

Max coil ring nut torque

Nm

1

Class of protection

IP65 with coil and connector mounted

Noise level

Max. 78 dBA with silenced relief

B10d

50 x 10

6

cicli

Category - ISO EN 13849

4

DC

High (99 %)

PL - ISO EN 13849

Suitable for use in safety circuits up to PL=e

* To avoid malfunctions, we recommend using Metal Work accessories.

Mount the coil on the

pilot and tighten the

locking nut (max 1 Nm)

The port number is shown

on valve

The electrical connection of the

sensor must be as indicated

Check the order code is

correct

Connect the air tubes to

the base using pneumatic

fittings

Pilot (only SES

versions)