-8-

Apply specified amount of grease to the following portions.

Grease (SEP-3A)

• Surface of the Base Ass’y

[54]

where Liner (A)

[52]

slides ·································· 5 g

• Surface of Shaft (B)

[55]

where the Turn Table

[25]

slides ··································· 0.5 g

• Surface of the Turn Table

[25]

where Liner (A)

[52]

slides ··································· 3 g

• Pinion of the Rotor Ass'y

[100]

and tooth surface

and gear chamber of the Spindle Ass'y

[75]

··················································· 15 g

• Surface of Shaft (D)

[10]

·············································································· 1 g

• Surface of the O-ring (P-6)

[15]

of the Stopper Pin Ass'y

[14]

······························ 0.2 g

• Surface of the Hinge

[13]

where the Turn Table

[25]

slides ·································· 2 g

• Surface of the Gear Case

[2]

where the Hinge

[13]

slides (grease chambers) ········· 5 g x 2 places

• Inside of the Spring

[5]

················································································ 5 g

• Surface of the Hinge

[13]

where Shaft (C)

[12]

slides ········································· 1 g

• Sliding surface of the Link

[89]

······································································ 0.2 g

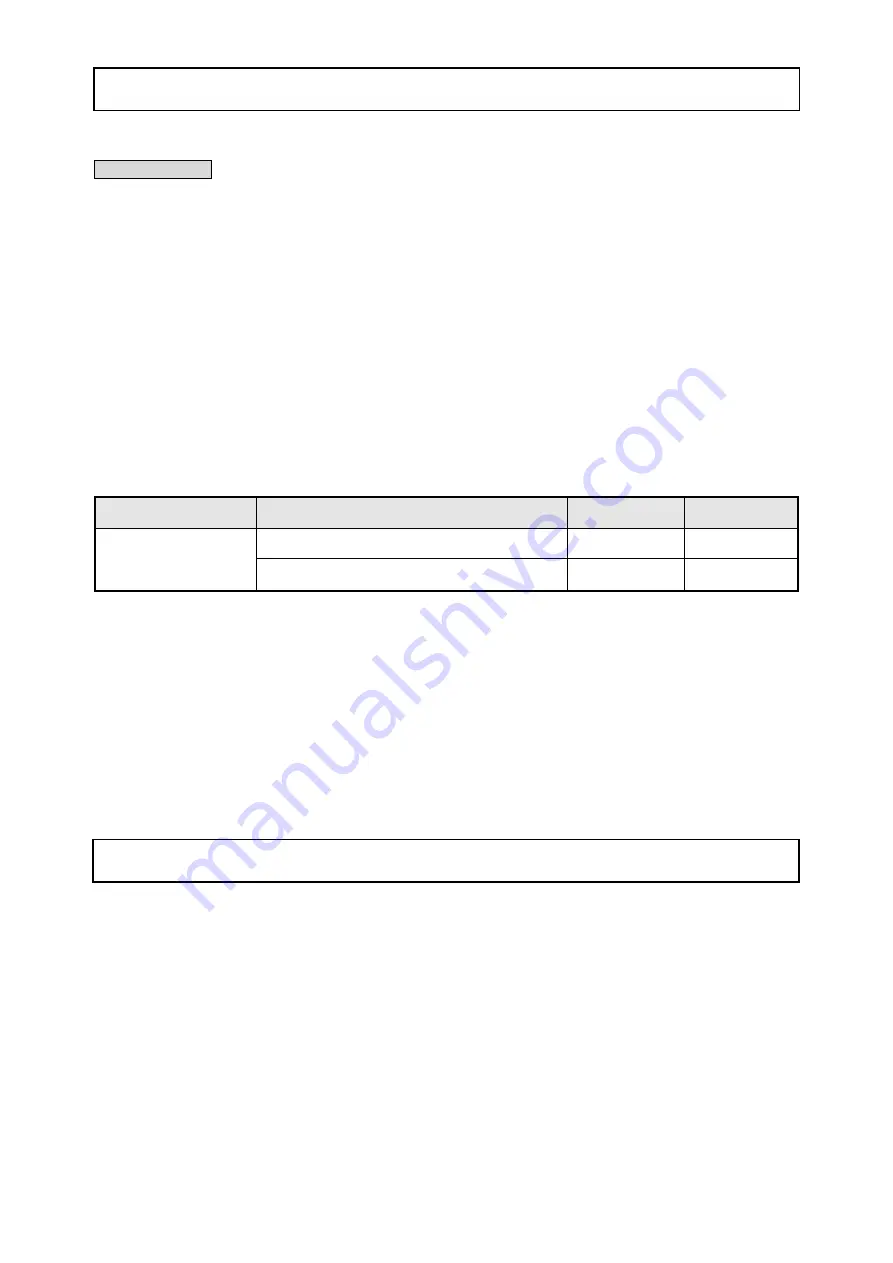

Please purchase the following grease as necessary.

Item

Registered part name

Net weight

Code No.

Grease (SEP-3A)

Grease (SEP-3A) (100 g)

100 g

930035

Grease (SEP-3A) (2.5 kg)

2.5 kg

930038

Advise the customer to lubricate the machine as indicated below at least once a month. Prior to lubrication,

any sawdust, dirt or other foreign matter should be thoroughly wiped away with a soft cloth.

(1) Swiveling section of the Gear Case

[2]

and Hinge

[13]

Coat the swiveling and sliding portions of the Gear Case

[2]

and the Hinge

[13]

with machine oil.

(2) Vise ass’y section

Coat the screw thread portion of the Knob Bolt M10 x 66

[35]

of the Vise Ass’y

[33]

with machine oil.

(3) Swiveling section of the Turn Table

[25]

and Hinge

[13]

Coat the swiveling and sliding portions of the Turn Table

[25]

and Hinge

[13]

with machine oil.

1. Checking after reassembly

• Check that the motor section can be moved up and down smoothly by holding the handle portion of the

Switch Handle Set

[106]

with operating force 58.8 N {6.0 kgf} max.

• Check that the Turn Table

[25]

can be rotated to the left and right smoothly by holding the Side Handle

[26]

with operating force 34.3 N {3.5 kgf} max. while the index stopper is released by pushing down the

Spring Plate

[29]

.

• Check that the Lower Guard

[90]

moves smoothly and properly.

• Check that the Off Lock Lever

[113]

and Trigger

[110]

operate smoothly and properly.

• Check that the motor does not start by pulling the Trigger

[110]

without moving the Off Lock Lever

[113]

of

the Switch

[114]

(switch operating force:100 N {10 kgf}).

• Check that LED

[84]

turns on and off by pushing the LED button.

• Check for braking (blade stopping time: 5 seconds max.)

• Check that the rotating direction of the spindle is the same as the arrow mark on the Gear Case

[2]

.

Lubrication points and type of lubricant

Checking and adjustment after reassembly