9

ENGLISH

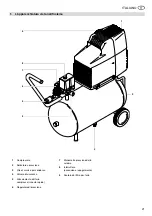

3.3 Safety devices

Safety valve

The spring safety valve

is incorpo-

rated into the pressure switch unit. The

safety valve opens if the max. permissi-

ble pressure is exceeded.

4.1 Prior to initial operation

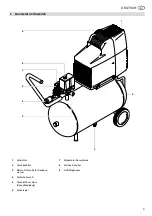

Wheel installation

1.

Install wheels as illustrated.

2.

Place starlocks on the wheels so

that the starlock's

tioned exactly opposite the receiving

grooves of the wheels

Then

push the starlocks onto the wheels.

4.2 Mains connection

B

Danger! High voltage

Operate machine in dry envi-

ronment only.

Operate machine only on a power

source complying with the following

requirements:

−

outlets properly installed, earthed

and tested;

−

fuse protection in accordance

with the Technical Specifications.

Position power cable so it does not

interfere with the work and is not

damaged.

Always check to see that the machine

is switched OFF before plugging in.

Protect power cable from heat,

aggressive liquids and sharp edges.

Use only extension cables with suffi-

cient lead cross section (see "Techni-

cal Specifications").

Do not stop the compressor by

unplugging, but switch OFF using the

switch.

Unplug after use.

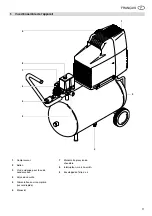

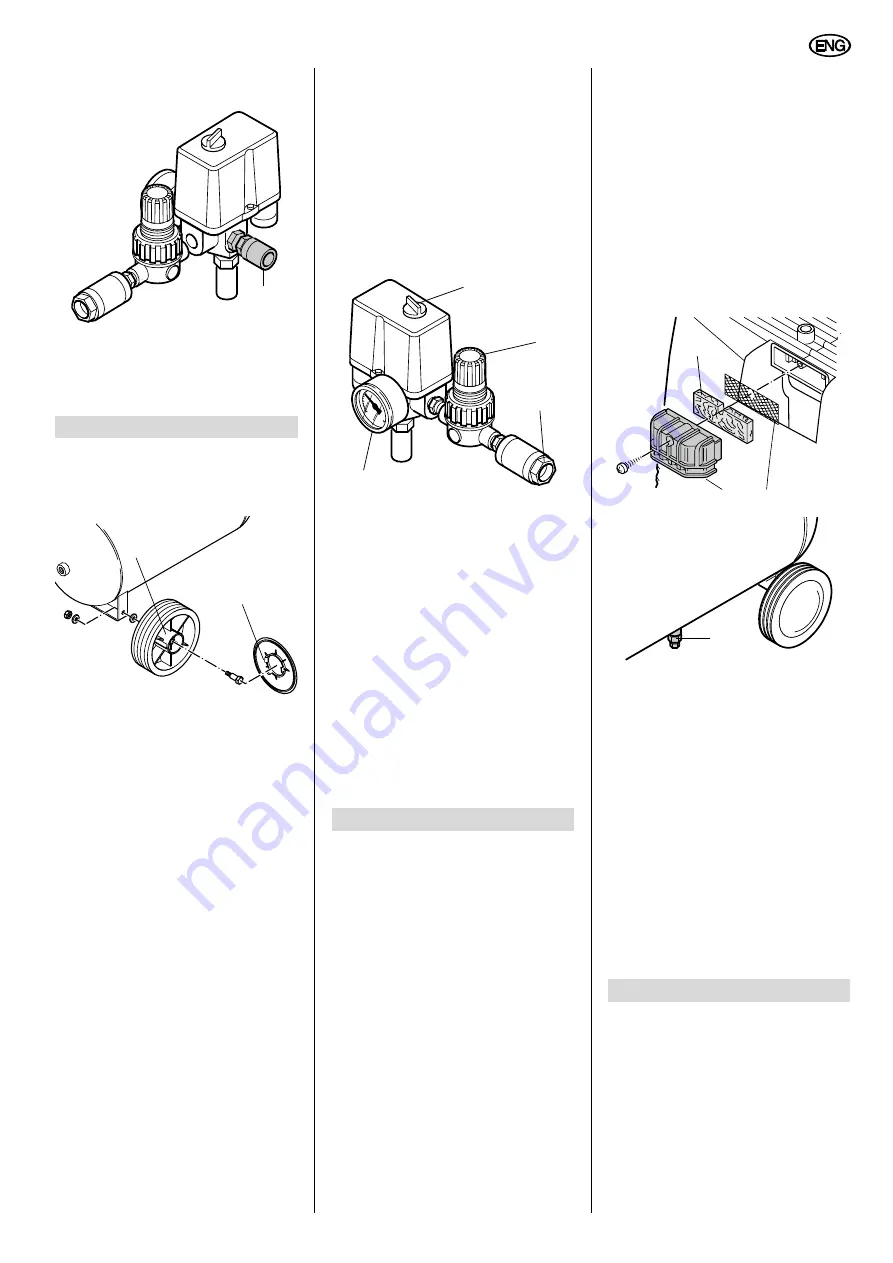

4.3 Generating compressed

air

1.

Start compressor

and wait until

the max. tank pressure is reached

(compressor shuts off). The tank

pressure is indicated by the tank

pressure gauge

2.

Set pressure regulator

required working pressure.

A

Caution!

The regulated pressure may

not be set higher than the max. wor-

king pressure of the connected air

tools!

3.

Connect air hose to compressed air

outlet

4.

Connect air tool.

You are now ready to work with the

air tool.

5.

Switch the compressor OFF, if you

do not continue working immediately

afterwards. Unplug after switching

OFF.

A

Danger!

Prior to all servicing:

−

Switch Off.

−

Unplug.

−

Wait until the compressor has

come to a complete stop.

−

Ensure the compressor and all air

tools and accessories connected

to it are relieved from pressure.

After all servicing:

−

Check to see that all safety

devices are operational.

−

Make sure that no tools or other

parts remain on or in the

machine.

Repair and maintenance work other

than described in this section must

only be carried out by qualified speci-

alists.

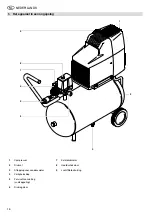

5.1 Periodic maintenance

Prior to each use

•

Check air hoses for damage,

replace if necessary.

•

Check all screwed connections for

tightness, tighten if necessary.

•

Check power supply cable for dam-

age, if necessary have replaced by

a qualified electrician.

Every 50 operating hours

•

Check air intake filter , clean if nec-

essary

•

Drain condensate

Every 250 operating hours

•

Replace air filter element.

5.2 Machine storage

1.

Switch unit OFF and unplug.

2.

Release pressure from tank and all

connected air tools.

3.

Store machine in such way that it

cannot be started by unauthorized

persons.

A

Caution!

Do not store machine unpro-

tected outdoors or in damp environ-

ment.

Do not lay machine on its side for

transportation or storing.

A

Danger!

Prior to all servicing:

−

Switch Off.

−

Unplug.

−

Wait until the compressor has

come to a complete stop.

−

Ensure the compressor and all air

tools and accessories connected

to it are relieved from pressure.

4. Operation

10

11

12

5. Care and Maintenance

15

14

13

16

6. Trouble Shooting

17

18