Set plate (A)

Blade

Groove

Fig. 29 (Correct installation)

Cutter block

Blade

3/64" (1 mm)

3/64" (1 mm)

Fig. 30

(2) Place the blade holder on the completed assembly,

as shown in Fig. 31, and fasten it with the three bolts.

Ensure that the bolts are securely tightened.

Blade holder

Bolt

Fig. 31

(3) Turn the cutter block over, and set the other side in the

same manner.

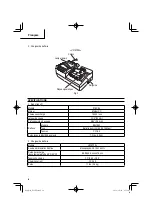

3. Adjustment of cutter blade height:

CAUTION

As the set gauge has been accurately factory

adjusted, never attempt to loosen it.

(1) Loosen the 2 screws holding on the blade and set

plate (A). (Fig. 32)

Machine screw

Fig. 32

(2) Press the turned surface of set plate (A) to the wall

surface b while adjusting the blade edge to the wall

surface a of the set gauge. Then, tighten them with the

2 screws. (Fig. 33, 34)

Machine screw

Fig. 33

Set gauge

Wall surface a

Blade

Set plate (A)

Wall surface b

Turned surface

Fig. 34

SHARPENING THE CUTTER BLADES

Use of the accessory Blade Sharpening Ass'y is

recommended for convenience.

(1) Use of Blade Sharpening Ass’y.

As shown in Fig. 35, two blades can be mounted on

the blade sharpening ass’y to ensure that the blade

tips are ground at equal angles. During grinding,

adjust the position of the cutter blades so that their

edges simultaneously contact the grinding stone as

shown in Fig. 36.

17

English

000Book̲P18DSL.indb 17

000Book̲P18DSL.indb 17

2018/10/16 17:38:41

2018/10/16 17:38:41

Summary of Contents for P 18DSL

Page 65: ...65 000Book P18DSL indb 65 000Book P18DSL indb 65 2018 10 16 17 38 46 2018 10 16 17 38 46 ...

Page 66: ...66 000Book P18DSL indb 66 000Book P18DSL indb 66 2018 10 16 17 38 46 2018 10 16 17 38 46 ...

Page 67: ...67 000Book P18DSL indb 67 000Book P18DSL indb 67 2018 10 16 17 38 46 2018 10 16 17 38 46 ...