TP-9579A

Issued 7-95

16579/22882

Page 2

© Copyright Meritor Automotive, Inc., 1995

Printed in the USA

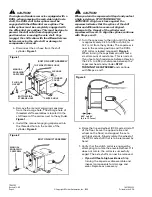

Brass Drift Method:

WARNINGS

To prevent serious eye injury, always wear safe

eye protection when you perform vehicle

maintenance or service.

WARNING

Do not strike the round driving lugs on the flange

of an axle shaft. Pieces can break off and cause

serious personal injury.

NOTE:

A 1.5-inch (38.1 mm) diameter brass

hammer can be used as a drift.

a. Hold a 1.5-inch (38.1 mm) diameter brass

drift against the center of the axle shaft

flange, INSIDE THE ROUND DRIVING LUGS.

Figure 2

.

b. Hit the end of the drift with a large hammer

(5 to 6 pounds, 2.3 to 2.7 kg) to loosen the

axle shaft and tapered dowels from the hub.

Figure 2

.

Air Hammer Method:

WARNINGS

To prevent serious eye injury, always wear safe

eye protection when you perform vehicle

maintenance or service.

a. Use an air hammer, such as Chicago

Pneumatic CP-4181-PULER, or equivalent,

with a round hammer bit to loosen the axle

shaft and dowels.

b. Put the round hammer bit against the axle

shaft flange between the studs, at different

points around the flange. Operate the air

hammer at each location and loosen the

axle shaft and tapered dowels from the hub.

Figure 3

.

7.

Identify each axle shaft that is removed from

the axle assembly so they can be installed in

the same location after transporting or repair is

completed. (Example: Match mark a mating

axle shaft and hub.)

8.

Remove the tapered dowels, gasket (if used)

and the axle shaft from the axle assembly.

Figure 1

.

9.

Install a cover over the open end of each hub

where an axle shaft was removed. This will

prevent dirt from entering the bearing cavity

and loss of lubricant.

NOTE:

If an air supply will be used for the brake

system of the transported vehicle, continue with

Steps 10 and 11, otherwise continue with Step 12.

10. Connect an auxiliary air supply to the brake

system of the vehicle that is being transported.

Before moving the vehicle, charge the brake

system with the correct amount of air pressure

to operate the brakes. Refer to the instructions

supplied by the manufacturer of the vehicle for

procedures and specifications. If an auxiliary

air supply is not used, continue with Step 12.

11. When the correct amount of air pressure is in

the brake system, release the parking brakes of

the vehicle that is being transported. Step 12 is

not required.

WARNING

When you work on a spring chamber, carefully

follow the service instructions of the chamber

manufacturer. Sudden release of a compressed

spring can cause serious personal injury.

12. If there are spring (parking) brakes on the

axle(s) that will remain on the road when the

vehicle is transported, and they cannot be

released by air pressure, manually compress

and lock each spring so that the brakes are

released. Refer to the manufacturer’s

instructions.

Figure 2

ROUND DRIVING LUG

Figure 3

AIR HAMMER

AND BIT