Mercury 6-5 Stat – Installation & User Guide

Network Configuration

The final section to set-up is the network address. In all instances, this must be done before the controller is

plugged into the site network. The controllers have an auto-initialise function, which will automatically log the

device onto the site network. If the wrong address has been entered onto the network, you will have to reset

the controller address by setting the address to 00-0, and then re-enter the correct address. (You may have to

deregister the wrong address from the home system as well).

To set the controller onto a network you must first connect the controller to a communications module. This is

either a: -

•

IP Futura or

•

Mercury

Hub

IP Futura module

In an IP system there are two options

•

IP-L

•

IP-r

IP-L allows you to fix an IP address into the controller, which you would use when you are connecting the

controllers onto a customer’s local area network. This would allow the customer to view each controller using

Internet Explorer

IP-r allows you to give each controller on the system a unique number. This number is then allocated a

dynamic IP address by the system DHCP server (such as the RDM Data Director)

IP-L

To configure the communication module for IP-L, set all three rotary switches to zero. The module should

then be connected to the controller.

1. nEt. From the function menu you can now select nEt

•

Press enter and the display will show “IP-L”, press enter

•

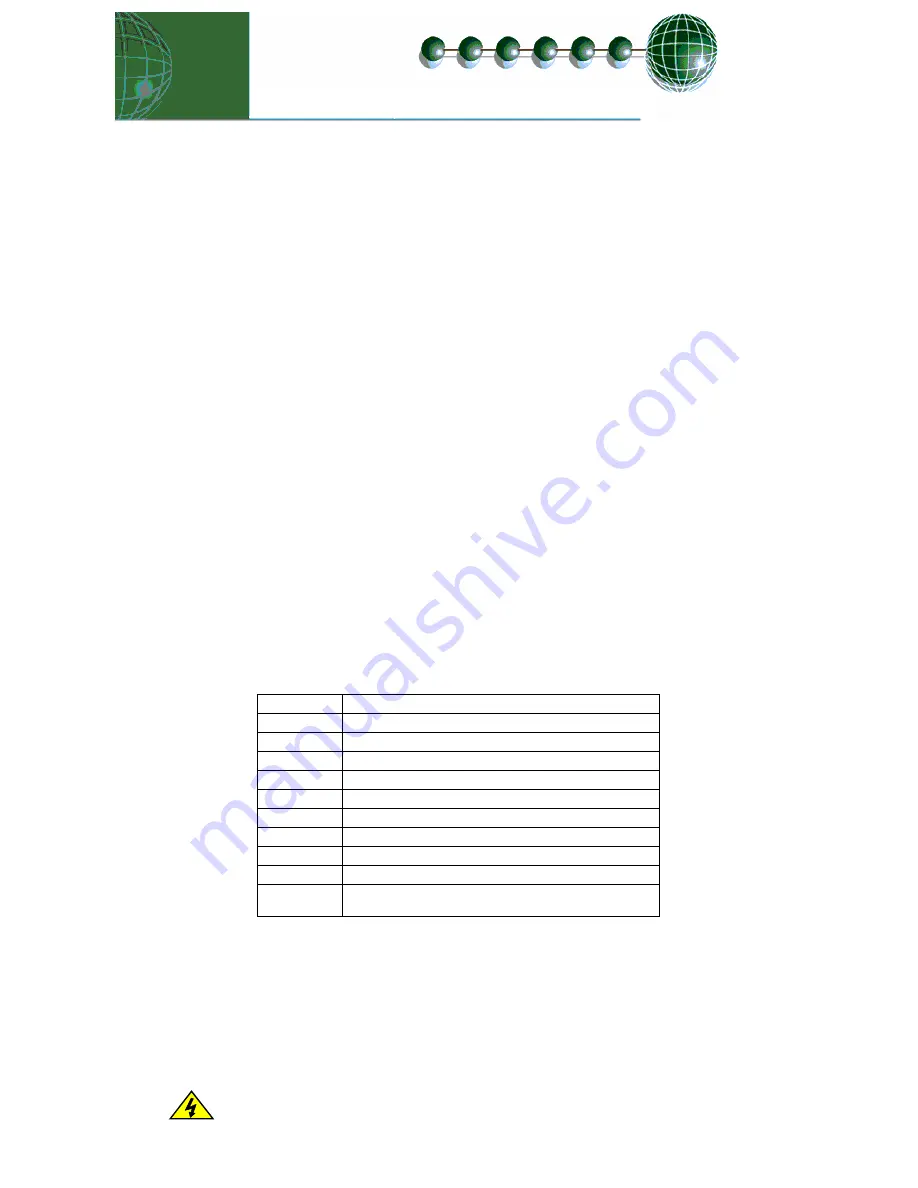

You can now set the address using the table below

Display

Option

IP-1

IP Address byte 1

IP-2

IP Address byte 2

IP-3

IP Address byte 3

IP-4

IP Address byte 4

nL Network

Mask

Length

gt-1

Gateway Address byte 1

gt-2

Gateway Address byte 2

gt-3

Gateway Address byte 3

gt-4

Gateway Address byte 4

ESC

Exit network menu.

N.B.

this option

must

be selected

to save any changes made in this menu

IP-r

To configure the communication module for IP-r, set the three rotary switches to give each controller a unique

identifier. The module should then be connected to the controller and the network.

The green network LED on the controller will flash until it has been logged on to the network. The Green

network LED will remain permanently on while it is on-line.

Ensure that all power is

Please refer to the Mercury Hub user guide, which can be obtained from the RDM website, for information

regarding connecting a controller to a network.

switched off before

installing or maintaining

this product

Revision 1.2

Page 10 of 21