−

If you modify spray gun, it cannot provide sufficient performance. Also, a failure of the machine may result.

2.

Stop other equipment.

−

To conduct spray work in an operating area of other equipment (robot, reciprocating equipment, etc.), confirm that the equipment has stopped first.

−

If you touch a robot or reciprocating equipment, you may get injury.

3.

Do not use spray gun for food and chemicals.

−

Do not apply spray gun to food or chemicals.

−

Corrosion of paint circuit may result in an accident. Also, mixture of foreign substances may result in health disorder.

4.

If an abnormal condition occurs, immediately stop spray gun.

−

If you find a problem, immediately stop spray gun, and examine the cause of the problem. Do not use gun until the problem can be solved.

Installation

1.

Use clean compressed air.

−

Use clean compressed air that has passed through an air dryer or air filter. If contaminated air is used, it results in a failure in spray work.

2.

Ensure tight connections.

−

When connecting paint cup and air hose to spray gun, tighten them securely by using spanner. If the connection is loose, compressed air, paint and other liquids

may spatter over human body, painted work pieces and peripheral equipment, resulting in damage.

3.

Conform to the rated withstand pressure of hose.

−

Make sure that the air pressure supplied to air hose does not exceed the rated withstand pressure of hose. Do not use an old or damaged hose.

1.

Operating Procedure

1.

Mount a paint cup and air hose securely to the spray gun by using a spanner or other tool.

2.

Although it varies depending on the paint viscosity, property, and operating conditions, a recommended spraying pressure is between 0.15 to 0.25 MPa. Never

use spray gun at a pressure higher than the maximum operating pressure (0.69 MPa).

3.

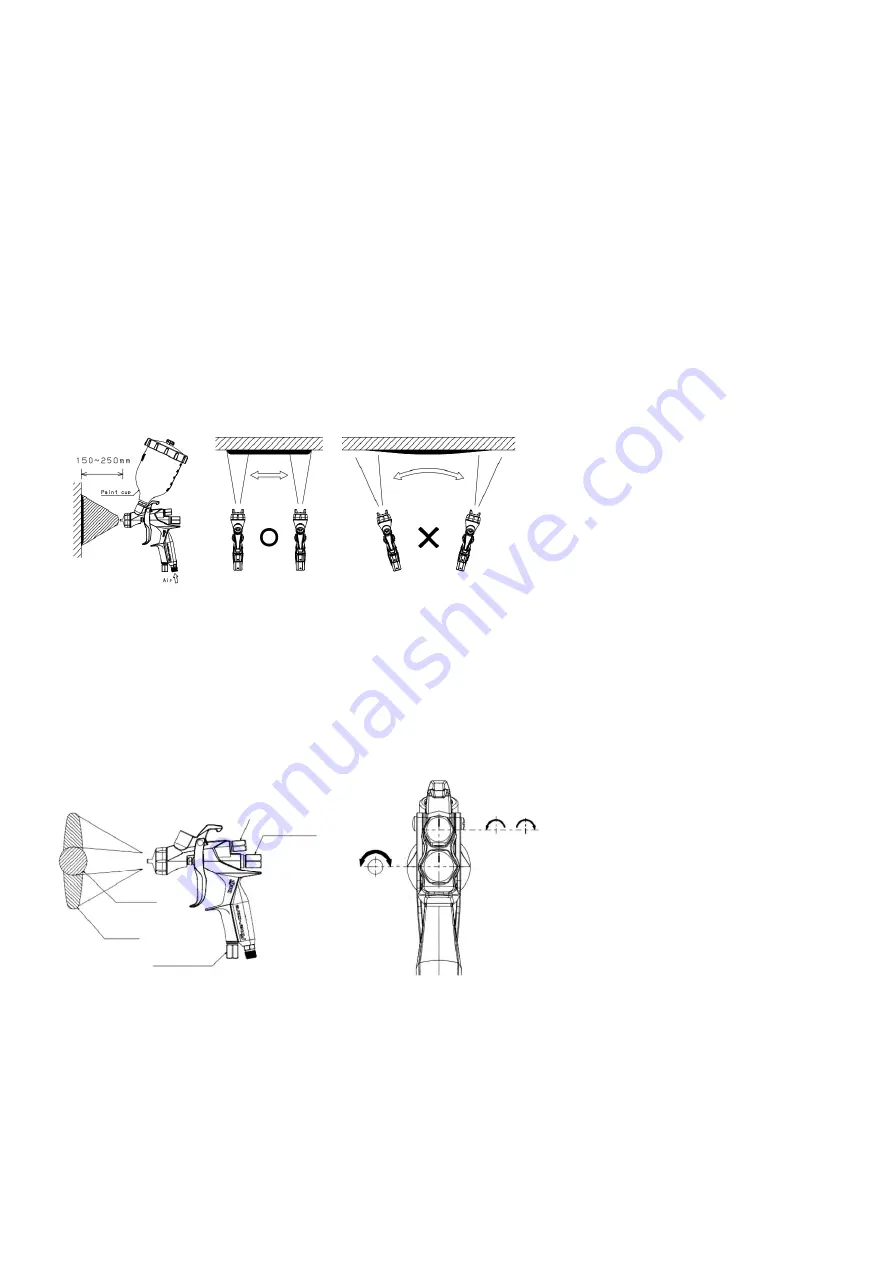

Recommended spraying distance is 150 to 250 mm. If spray gun is too close to a target work piece or it swings like an arc, good finished quality cannot be obtained.

4.

To obtain a uniformly finished condition, always hold spray gun at a right angle to the spraying surface.

5.

Tightening the air volume adjusting screw clockwise will decrease the air volume, and loosening the air volume adjusting screw counterclockwise will increase

the air volume.

6.

If you tighten the pattern adjusting screw by turning it clockwise completely, paint is sprayed in a spot pattern. As you loosen the pattern adjusting screw by

turning it counterclockwise, spray pattern area gradually increases. When you rotate the screw approximately three times, the pattern area becomes the

maximum. Adjust the spray pattern depending on the spray work step and the type of paint being used.

7.

If you tighten the paint adjusting screw by turning it clockwise, spray volume decreases. As you loosen the screw by turning it counterclockwise, spray volume

gradually increases. When you rotate the screw three to four times, spray volume becomes the maximum. Set paint volume depending on spray work

conditions.

Pattern adjusting screw

Paint adjusting screw

Clockwise (Spot

pattern)

Counterclockwise (Flat

pattern)

Air volume

adjusting screw

Counterclock wise

Clockwise

Rotation direction of paint adjusting screw

Max. Mín.

Rotation direction of

pattern adjusting screw