IM 685-1

15

Grasp the rod and while applying some thrust to the rod in

the direction of the actuator to take up any free play, and

with the bracket in alignment with the linkages that connect

to it, tighten the two set screws. Return the actuator to the

minimum rate position.

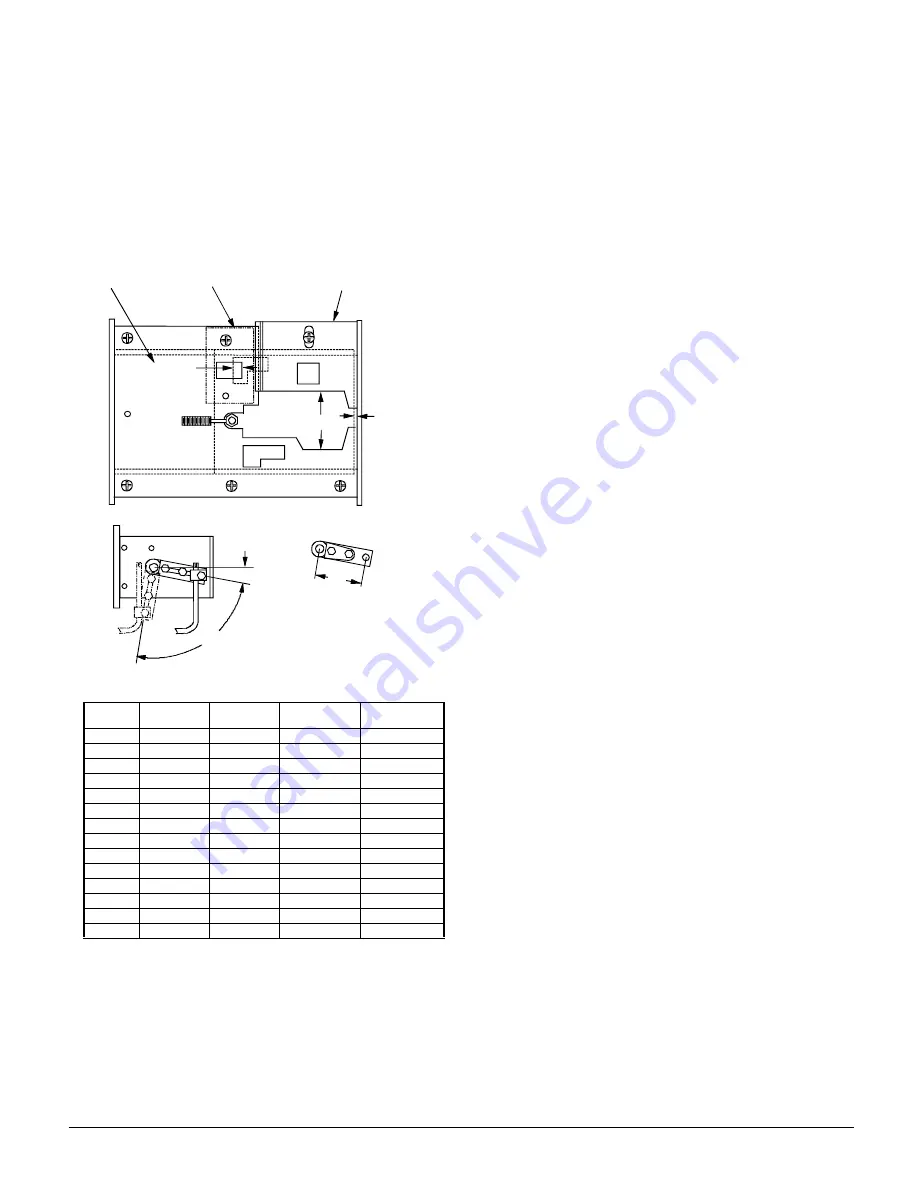

The adjustable plate (2), Figure 10a is positioned to provide

an opening per dimension "F".

Figure 10. Air and Gas Control Linkage

Actuator Crankarm

The actuator crankarm should not require adjustment. The

radius indicated by "G" dimension, Figure 10b will result in a

complete stroke from minimum to maximum, and provide the

correct amount of over travel to bottom out the linkage

bracket at the minimum rate position. Do not attempt to mod-

ify firing rates, etc. by changing the radius of the crackarm.

Switch Adjustment

Switches LS1 and LS2 prove maximum and minimum posi-

tion of the control rod. These switches are located in the con-

trol box switch compartment and have a limited range of

adjustment. When the two nuts that secure the switches are

loosened the switch will pivot on the inner stud and the outer

stud can be moved up and down. The switches should be

adjusted such that when the collar mounted on the actuator

rod is moved into position and pushes in the lever on the

switch, the switch will click to the "made" position, but the

lever will not bottom out against the switch body. When

properly adjusted the lever can move an additional 0.02

inches, as proven by slipping a feeler gauge between the

switch lever and the collar when in the "made" position. The

collar on the control rod should be adjusted so the switch

lever it is actuating will rest squarely on the outer surface of

the collar but only 0.03 inches from the edge. If the collar is

located for an engagement that is longer than 0.03 inches,

the collar may not reach the actuator on the other switch

when at the other end of its stroke.

Altitude Considerations

For altitudes of 2000 feet and higher, the gas burner must be

derated 4% for every 1000 feet of altitude.

Example: Model HT080 at an altitude of 3000 feet is derated

(0.04 x 3 = 0.12). At 1000 mbh input (1000 x 0.12 = 120

mbh), the actual input is (1000 - 120 = 880 mbh) at 3000 feet.

The method of derating the burner is to reduce the manifold

pressure. Multiply the Maximum Rate Manifold Pressure

shown under Column 8 in Table 5 by the following altitude

factors:

2000 feet = 0.845

5000 feet = 0.640

3000 feet = 0.774

6000 feet = 0.578

4000 feet = 0.706

7000 feet = 0.518

Model

HT***

D

E

F

G

020

.005

.116

.50

3.30

025

.005

.125

.83

3.30

032

.005

.101

.82

3.30

040

.005

.101

1.25

3.30

050

.020

.099

1.25

3.30

064

.020

.136

1.60

3.30

065

.020

.136

1.60

3.30

079

.020

.106

1.88

3.30

080

.020

.106

1.88

3.30

100

.020

.110

2.44

3.30

110

.020

.136

1.05

4.28

140

.020

.136

3.30

4.28

150

.020

.140

3.30

4.28

200

.020

.140

4.40

4.28

90º

10º

G

MIN

RATE

c

PROFILE

PLATE

d

ADJUSTABLE

PLATE

e

PRIMARY AIR

COLLECTOR

E

F

D

Figure 10b

Summary of Contents for SuperMod IM-685-1

Page 27: ...IM 685 1 27 Notes ...