Installation and use

COMPUTER XP805

28

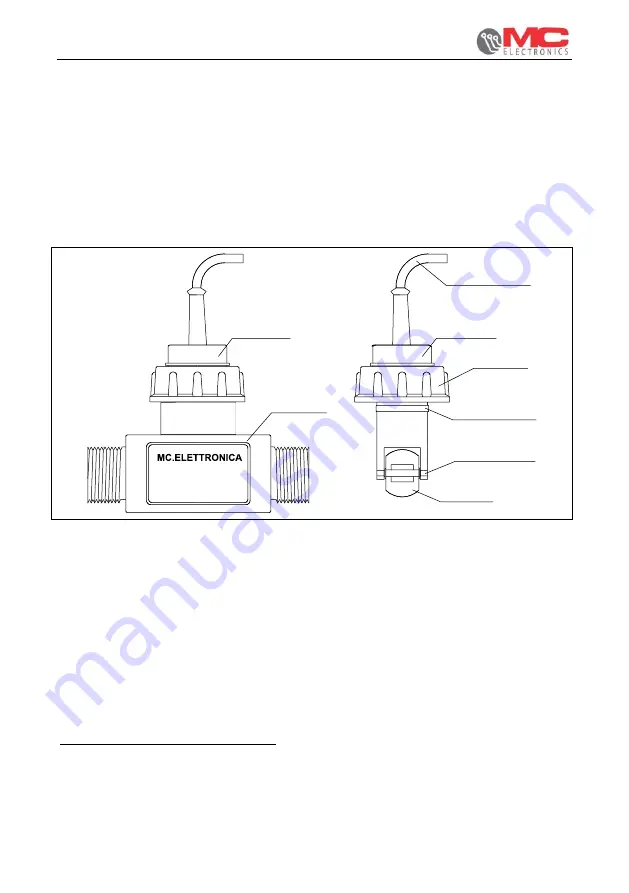

7.2.1 Maintenance of the flowmeter sensor

We recommend checking the cleanliness and state of wear of the flowmeter sensor

rotor periodically. Proceed as follows to carry out this operation:

1. Unscrew the sensor ring nut completely (Figure 9) and extract the sensor from

the main body (there will be some resistance from the O-ring);

2. Make sure that dirt is not found on the rotor or between the rotor and ceramic

axis;

3. Make sure there is no mechanical clearance on the rotor shaft

1

;

Figure 8

.

4. Reinsert the sensor, making sure that the fixing notches match

2

(Figure 10);

1

Excessive clearance means a range which is higher than 1 mm.

2

Before screwing the ring nut, it is necessary to remove the resistance of the O-ring

and check that the sensor does not turn inside its seat.

sensor

body

electric cable

sensor

ring nut

O-Ring

Rotor axis

in ceramic

rotor