12

7.3.

Battery

If the machine is not used for a long period of

time, disconnect the battery removing the cable

terminal from the positive pole (Fig. 9 No. 2). For

maintenance, consult the instruction and use

leaflet of the battery.

IMPORTANT:

Recharge the battery in a dry place.

Protect the contacts from dirt and water

stagnation. Do not spray with water.

Replacing the Battery (Fig. 9)

Handle the battery with particular care

since it contains acid.

1. Remove the protective cover and unhook

the two hooks.

2. Remove the connection terminals and

take care to first remove the negative one

(4) in order to prevent a short circuit.

3. Extract the battery and replace it with one

with the same characteristics (45 Ah).

Dispose

of

the

battery

in

the

appropriate manner in accordance

with the regulations in force in the

country of use.

7.4.

Cleaning the Machine

Clean the float machine at the end of each

working day to prevent cement from hardening

and forming encrustations on the machine. Wash

the dirty parts with a brush and water. Wet the

parts exposed to cement with “stripping” oil (never

fuel oil). Do not oil the rubber moving parts (belts,

etc.).

7.5.

Replacing the Floats

Be careful when installing the machine. One rotor

turns clockwise and the other counter-clockwise,

therefore you need to check that the various

components have been properly arranged.

Before mounting the floats, check that the blades

are clean, i.e. that there are no traces or residues

of cement mixes. The blades must be placed in

the horizontal position using the knobs (Fig. 4 No.

1 & 2).

To replace the floats proceed as follows:

Slightly lift the float machine off the ground (about

10 cm).

Mount the floats on the blades checking the

correct direction of rotation.

When the floats have been mounted, reposition

the float machine on the ground.

7.6.

Replacing the Blades

Always check the state of wear of the blades and

replace if they are damaged or bent. For proper

function all blades need to be replaced.

To replace the blades, proceed as follows (Fig.

10):

Clean any working residue off the

float machine.

Open the guard by unscrewing the

two fixing bolts and hook the guard to the

chain.

Slightly lift the float machine off the

ground (about 10 cm).

Remove the fixing bolts of the blades

on each arm.

Mount the new blades and fix the

bolts with the respective split washers (check

the state of the bolts and replace them if

necessary).

When

the

blades

have

been

mounted, reposition the float machine on the

ground.

Reposition the guard and tighten the

bolts.

7.7.

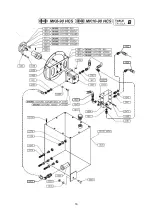

Replacing the Belts

To replace the belts, operate as follows:

Dismantle the belt protection guard

(Fig. 11 No. 1).

Slightly lift the float machine off the

ground (about 10 cm) in order to be able to

freely turn the pulley and the clutch and thus

easily remove and replace the belts.

Loosen the belt tightener.

Remove the worn belts and replace

them with ones of the same size.

Screw down the belt tightener until

the ideal tension is obtained.

Reposition the float machine on the

ground.

Reposition the guard (1).

7.8.

Gear Reduction Oil Level

To check the oil level in the gear reductions,

follow the instructions below:

There are two caps on the side of the two gear

reductions. The top cap (Fig. 12 No. 1)

determines the oil level in the gearbox. Pay

particular attention when you notice oil in the

lower part of the float machine. Clean and check

where the leak is coming from and take the

appropriate action.

Should the oil need to be topped off, use Mobil

Glygoyle 30 synthetic oil or equivalent. Check the

level on the gauges (2).

To replace the oil filter, open the support (3),

unscrew the filter (4) and proceed with

replacement.

Summary of Contents for 1830041

Page 3: ...3...

Page 14: ...14 7 11 Parts List...

Page 15: ...15...

Page 16: ...16...

Page 17: ...17...

Page 18: ...18...

Page 19: ...19...

Page 20: ...20...

Page 21: ...21...

Page 22: ...22...

Page 23: ...23...

Page 24: ...24...

Page 25: ...25...

Page 26: ...26...

Page 27: ...27...

Page 28: ...28...

Page 29: ...29...

Page 30: ...30...

Page 31: ...31...

Page 32: ...32...

Page 33: ...33...

Page 34: ...34...

Page 35: ...35...

Page 36: ...36...

Page 37: ...37...

Page 38: ...38...

Page 39: ...39...

Page 40: ...40...

Page 41: ...41...

Page 42: ...42...

Page 43: ...43...

Page 44: ...44...

Page 45: ...45...

Page 46: ...46...

Page 47: ...47...

Page 48: ...48...

Page 49: ...49...

Page 50: ...50...

Page 51: ...51...

Page 52: ...52...

Page 55: ...55 NOTES...