26

Cycle Signal

The End of Cycle Signal produces an audible sound when the drying cycle is finished.

Promptly removing clothes at the end of the cycle reduces wrinkling.

Press SIGNAL ON/OFF. The light on the control will glow yellow when the Cycle Signal is on.

NOTE:

When the WRINKLE PREVENT feature is selected and the End of Cycle Signal is on, an

audible sound will be emitted every 5 minutes until the clothes are removed, or the WRINKLE

PREVENT feature is finished.

Changing Cycles, Options and Modifiers

You can change Sensor Cycles, Timed Cycles, Modifiers and Options anytime before pressing

Start.

NOTE:

Three short tones sound if an unavailable combination is selected. The last selection

will not be accepted.

Changing Cycles after pressing Start

1.

Press START/PAUSE once. This pauses the current cycle.

2.

Select the desired cycle and options.

3.

Press and hold START/PAUSE. The dryer starts at the beginning of the new cycle.

NOTE:

If you do not press START/PAUSE within 5 minutes of selecting the cycle, the dryer

automatically shuts off.

Changing Modifiers and Options after pressing Start

You can change a Modifier or Option anytime before the selected Modifier or Option begins.

1.

Press START/PAUSE once.

2.

Select the new Modifier and/or Option.

3.

Press and hold START/PAUSE to continue the cycle.

Changing the Preset Sensor Cycles Dryness Settings

If all your loads on all Sensor cycles are consistently not as dry as you would like, you may

change the preset Sensor Cycles Dryness settings to increase the dryness. This change will

affect all of your Sensor cycles.

Your Sensor Cycles Dryness settings can be adjusted to adapt to different installations,

environmental conditions or personal preference. There are 3 drying settings: 1 (factory preset

dryness level), 2 (slightly dryer clothes, approximately 15% more drying time) and 3 (much

dryer clothes, approximately 30% more drying time).

1.

The Sensor Cycles Dryness settings cannot be changed while the dryer is running.

2.

Press and hold the Sensor Cycles Dryness button for 5 seconds. The dryer will beep, and

“CF” will be displayed on the Estimated Time Remaining screen for 1 second followed by

the current drying setting.

3.

To select a new drying setting, press the Sensor Cycles Dryness button again until the

desired drying setting is shown.

NOTE:

While cycling through the settings, the current setting will not flash, but the other

settings will flash.

4.

Press START/PAUSE to save the drying setting.

5.

The drying setting you selected will become your new preset drying setting for all Sensor cycles.

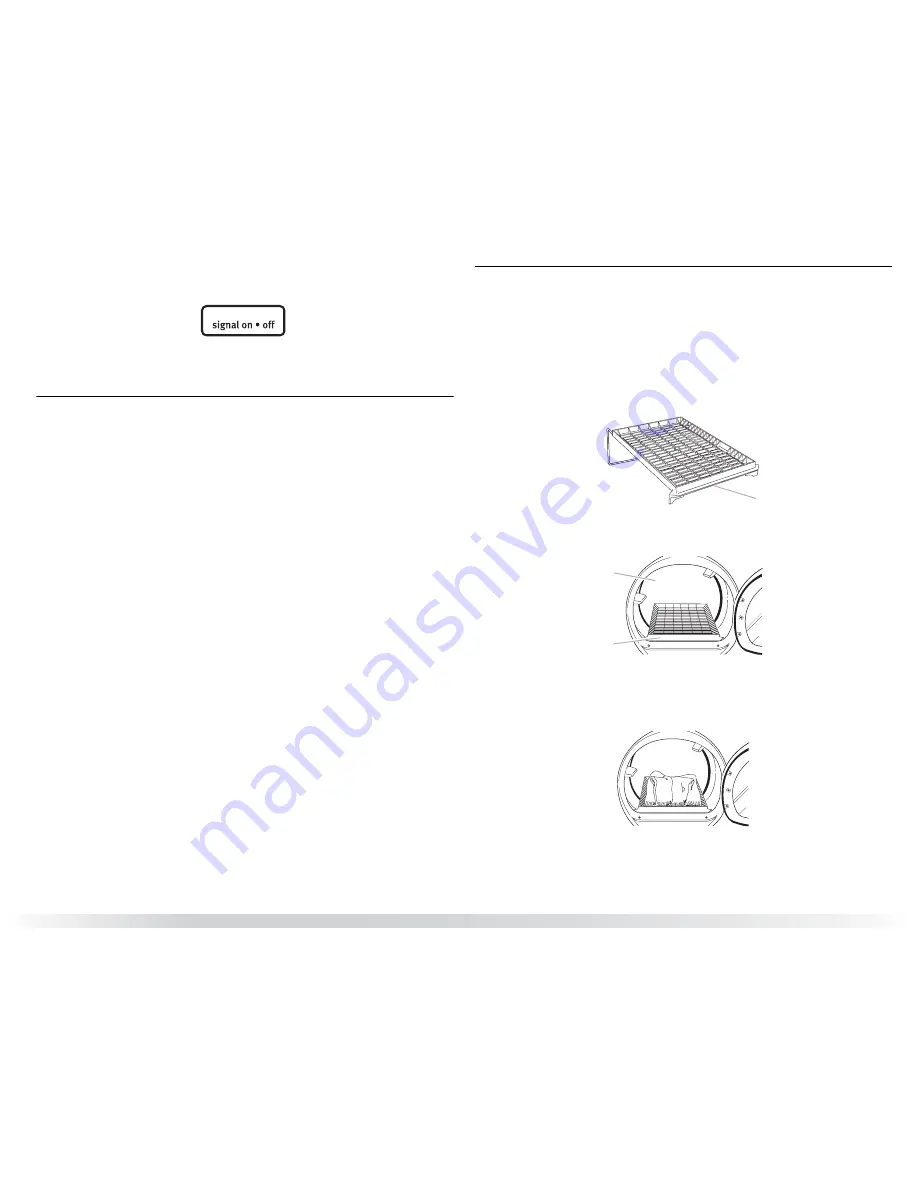

Drying Rack Option

The drying rack is useful for drying items you would not necessarily want to tumble dry or that

you would normally line dry (for example, sweaters).

If your model does not have a drying rack, you may be able to purchase one for your model.

To find out whether your model allows drying rack usage and for information on ordering,

please refer to the front page of the manual or contact the dealer from whom you purchased

your dryer.

To use the drying rack

Do not remove the lint screen.

1.

Open dryer door.

2.

Place drying rack inside dryer drum, positioning the back wire on the ledge of the inner

dryer back panel. Push down on front edge of drying rack to secure over the lint screen.

3.

Put the wet items on top of the drying rack. Leave space between the items so air can

reach all the surfaces.

NOTE:

Do not allow items to hang over the edge of the drying rack.

4.

Close the door.

5.

Select a timed drying cycle and temperature (see following chart). Items containing foam,

rubber, or plastic must be dried on a clothesline or by using the Air Dry temperature

setting.

6.

You must select a time by pressing the TIME ADJUST up or down buttons. Reset time as

needed to complete drying. Refer to the following table.

A. Front edge

A. Dryer rack front edge

B. Dryer back panel

A

A

B