Installation and Operational Instructions for

EAS

®

-HT clutch Type 405_._ _400

Sizes 7

– 10

(B.4050.1.EN)

16/04/2019 TK/GH/SU

Chr. Mayr GmbH + Co. KG

Eichenstraße 1, D-87665 Mauerstetten, Germany

Tel.: +49 8341 804-0, Fax: +49 8341 804-421

Page 6 of 9

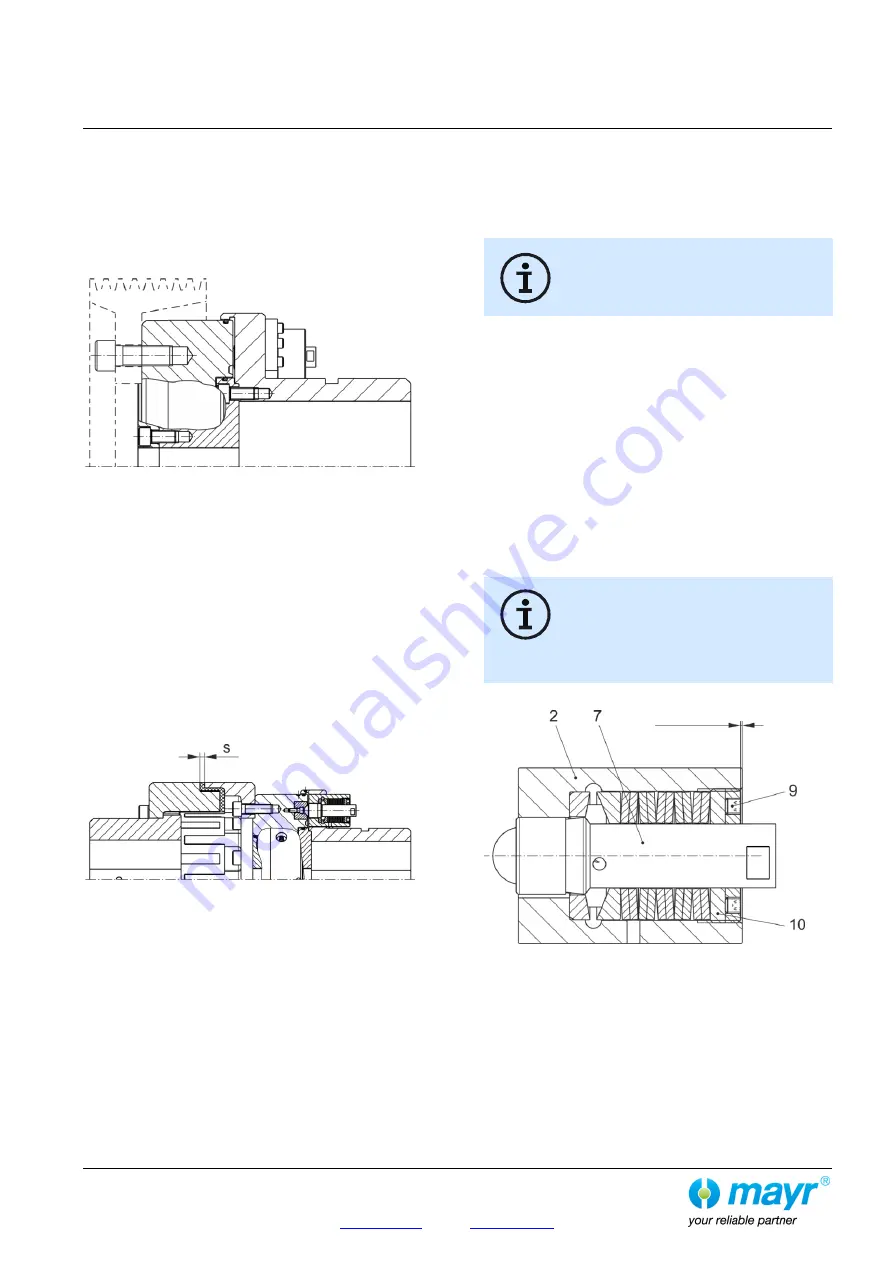

Design with Short Bearing-Supported Hub

Type 4050._ _400 (Figs. 1 and 7)

The design Type 4050._ _400 consists of Items 1 to 14, see

Fig. 1.

The output element can be mounted directly onto the bearing-

supported output-side pressure flange (3) of the clutch. Please

find the maximum permitted forces on the flange connection in

radial and axial direction in Table 3.

Fig. 7

EAS

®

-lastic Design

Type 4053._ _400 (Figs. 1, 2 and 8)

The EAS

®

-HT clutch, combined with a positive-locking, flexible

coupling component, consists of Items 1 to 22, see Figs. 1 and

2.

The flexible coupling component (Items 15

– 22) is in simple

plug-in coupling form and compensates for axial, radial and

angular shaft misalignments, whereby the total sum of

misalignments must not exceed 100 %.

When installing the clutch, the EAS

®

-clutch component and the

flexible component are mounted onto the shafts (input and

output) and secured axially. After this, both clutch/coupling

components can be joined to dimension “s” (see Fig. 8 and

Table 2, page 8).

Fig. 8

Torque Adjustment (Fig. 8)

Set the limit torque M

G

for overload on the clutch by changing

the cup spring pre-tension on each overload element (2)

according to the Adjustment Diagram.

On the clutches the adjusting nut (9) is adjusted by turning it in

the overload element (2) using a face wrench.

During torque adjustment, please ensure that

all overload elements (2) on the clutch are

evenly adjusted!

Torque Adjustment:

1. Determine the limit torque M

G

for overload.

2.

Please determine dimension “a” using the Adjustment

Diagram included in the clutch delivery.

This dimension is equal to the required limit torque M

G

.

3.

If necessary, unscrew the switching disk

(23) and remove

the cap screws (24).

4.

Loosen the locking set screws (10) on the

adjus

ting nuts (9).

5. Set all overload elements (2) by turning the adjusting nut (9)

to the dimension “a” (Fig. 9) found in the Adjustment

Diagram.

6.

Tighten the locking set screws (10) again in the

adjusting

nuts (9).

7.

If necessary, screw the

cap screws (24) via the switching

disk (23) in the bolts (7); then tighten them with a tightening

torque acc. Table 3.

In order to guarantee low-wear clutch operation,

it is essential that the clutch torque is set to a

sufficiently high service factor (overload torque to

operating torque). Our experience has shown

that an adjustment factor of 1.5 to 4 gives good

results. On very high load alternations, high accelerations and

irregular operation, please set the adjustment factor higher.

Fig. 9

Dim. “a”