INSTALLATION MANUAL CT550

8

The hydraulic directional control valve (DCV) must be equipped with a pressure gauge and pressure relief

valve and should preferably be placed as close as possible to the thruster unit.

The piping can be flexible or a mix of rigid and flexible type and should have crimp-connected fittings.

The piping should match interior diameters and the service pressure equal or above that which has been

recommended.

The circuits must be as direct as possible and avoid any bends and joints.

The circuits must be clean and closed-off until final connection takes place.

The thruster hoses arriving at the thruster must be of the thermo-plastic non-conductive type.

The hydraulic motor drain line and the return T-line of the DCV should each go separately and directly, back

into the top of the oil tank.

Use synthetic, mineral or vegetable hydraulic oil, to ISO standard 32 to 48

8.

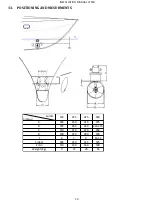

HYDRAULIC SPECIFICATIONS

CT550 Specifications

Power

49 KW

Pressure

250 bar

Flow

125 - 141 lt/min

Detailed instructions and diagrams are delivered with each pack, specific to the installation chosen.

9.

MAINTENANCE

In order to ensure peak performance from your thruster, the tunnel, the leg and the propellers must be kept

clean.

IMPORTANT:

In order to prevent chalky deposits, which cause damage to the oil seals, we recommend

cleaning the shaft and the oil seals first, then applying a layer of silicon oil before assembling the propellers.

ANNUAL BASIS:

CHANGE the anode (if necessary).

CHANGE the gear oil a minimum of every second year. Check the gearoil quality in the gearhouse

every time the boat is out of the water

CHECK the oil and the hydraulic filtration circuit (only if necessary).

EVERY 5 YEARS:

DRAIN hydraulic oil system and change the filter and refill.