INSTALLATION MANUAL CT550

4

1.

GENERAL INSTALLATION GUIDLINES

Decide on the best location for the thruster

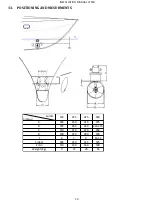

. (See drawing: “Positioning & Measurements” at back of manual).

The tunnel must be as low as possible and as far forward as possible.

The propellers must not protrude beyond the hull line.

The ideal position of the tunnel is such that there is at least the depth of one tunnel diameter from the water

line to the top of the fitted tunnel. Decreased performance of the thruster due to inadequate immersion depth

can be compensated by fitting the tunnel as far forward as possible (increasing lever arm movement).

Hydraulic thrusters can be fitted vertically, horizontally or tilting.

IMPORTANT:

When using tunnels of different thickness (example: metallic tunnel) it is imperative that the area

between the drive leg/gasket and the motor support, matches the thickness as indicated in the table on the

drawing “Positioning & Measurements” at back of manual and that the motor support is stable.

If you have less than 12 mm thickness, you will require an extra hard rubber gasket between the motor support

and the tunnel.

2.

TUNNEL

When the final tunnel position is determined (and all dimensions have been checked), mark the centre of the

tunnel’s position and drill a Ø 10 mm hole. Make up a metal compass from 8 mm rod with 212 mm radius.

Fit compass into the Ø 10 mm holes and trace the form of the tunnel on to the hull (elliptical).

After cutting out the elliptic hole, disc the interior surface of the hull, by approx. 10 to 15 cm around the holes.

The outside surface of the tunnel is then ready to be fibre-glassed.

Do not

stratify over

this zone