WARNING

Page 3

MT2421

MICRO 2" RANDOM

ORBIT SANDER

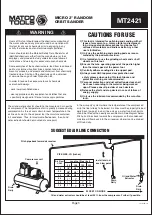

The oil and water extractor should not be mounted on or near the

air compressor. The temperature of air is greatly increased during

compression. As the air cools down to room temperature in the

air line on its way to the air power tool, the moisture contained

in it condenses. Thus, for maximum effectiveness, the oil and

water extractor should be mounted at some point

in the air supply system where the temperature of the compressed

air in the line is likely to be lowest. Air lines must be properly drained

daily. Each low point in an air line acts as a water trap. Such points

should be fitted with an easily accessible drain. See diagram below.

Pitch all air lines back towards the compressor so that condensed

moisture will flow back into the air receiver where it can be drained

off. Drain daily.

SUGGESTED AIR LINE CONNECTION

Pitch pipe back toward air receiver

Compressor unit

Drain

Daily

25 FEET OR MORE

Oil and water extractor should be at least 25 ft. from the compressor. Further if possible.

Drain

Daily

Drain

Daily

Oil and Water

Extractor

Install drain at

each low point

PIPE SIZE, I.D. (Inches)

Air Flow

CFM

Length of Pipe (feet)

10

20

30

40

50

70

50

1/2"

3/4"

3/4"

1"

1"

1"

100

3/4"

3/4"

3/4"

1"

1"

1"

150

3/4"

3/4"

1"

1"

1"

1-1/4"

200

3/4"

1"

1"

1"

1-1/4"

CAUTIONS FOR USE

Users of this tool should review the chemical composition of

the work surface and any products used in conjunction with

this tool for any such chemicals prior to engaging in any

activity that creates dust and/or microscopic particles.

Users should obtain the Material Safety Data Sheets for all

identified chemicals, either from the manufacturer or their

employer, and proceed to study, understand and follow all

instructions and warnings for exposure to such chemicals.

Some examples of these chemicals are: lead from lead based

paints; crystalline silica from bricks, cement and other

masonry products; and arsenic and chromium from chemically

treated lumber. A listing of the chemicals can be obtained

at www.oehha.ca.gov under Proposition 65.

In order to reduce their exposure to such chemicals

users should always:

- work in well-ventilated areas.

- wear appropriate safety equipment and clothes that are

specifically designed to filter out microscopic particles

1512179-14

1) This tool is intended for polishing and sanding with all

types of movement e.g. rotary, orbital and reciprocat-

ing, using coated abrasive product and bonnets of

various soft materials and endless belts. Any other

use is forbidden.

2) Only use the polishing and sanding pads as recom-

mended by the pad manufacturer.

3) It is forbidden to use the grinding wheels and cut-off

wheels on this tool.

4) Ensure the max. operating speed of the pad is higher

than the rated speed of the power tool.

5) Centrally adhere sanding disc to support pad.

6) Always wear ANSI approved ear protection and

safety glasses when using this tool. Gloves and

protective clothing are recommended.

7) Personal protection and dust collection devices shall

be chosen according to the material being worked

upon. Please consult provider of such devices.

8) Release the start and stop device in case of failure of

energy supply.

9) Only use the lubricant recommended by the manufac-

turer.